Process for preparing sophocarpine

A preparation process and a technology for sophocarpine, which are applied in the field of the preparation process of sophocarpine, can solve the problems of staying, unsuitable for industrial production and the like, and achieve the effects of high yield and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

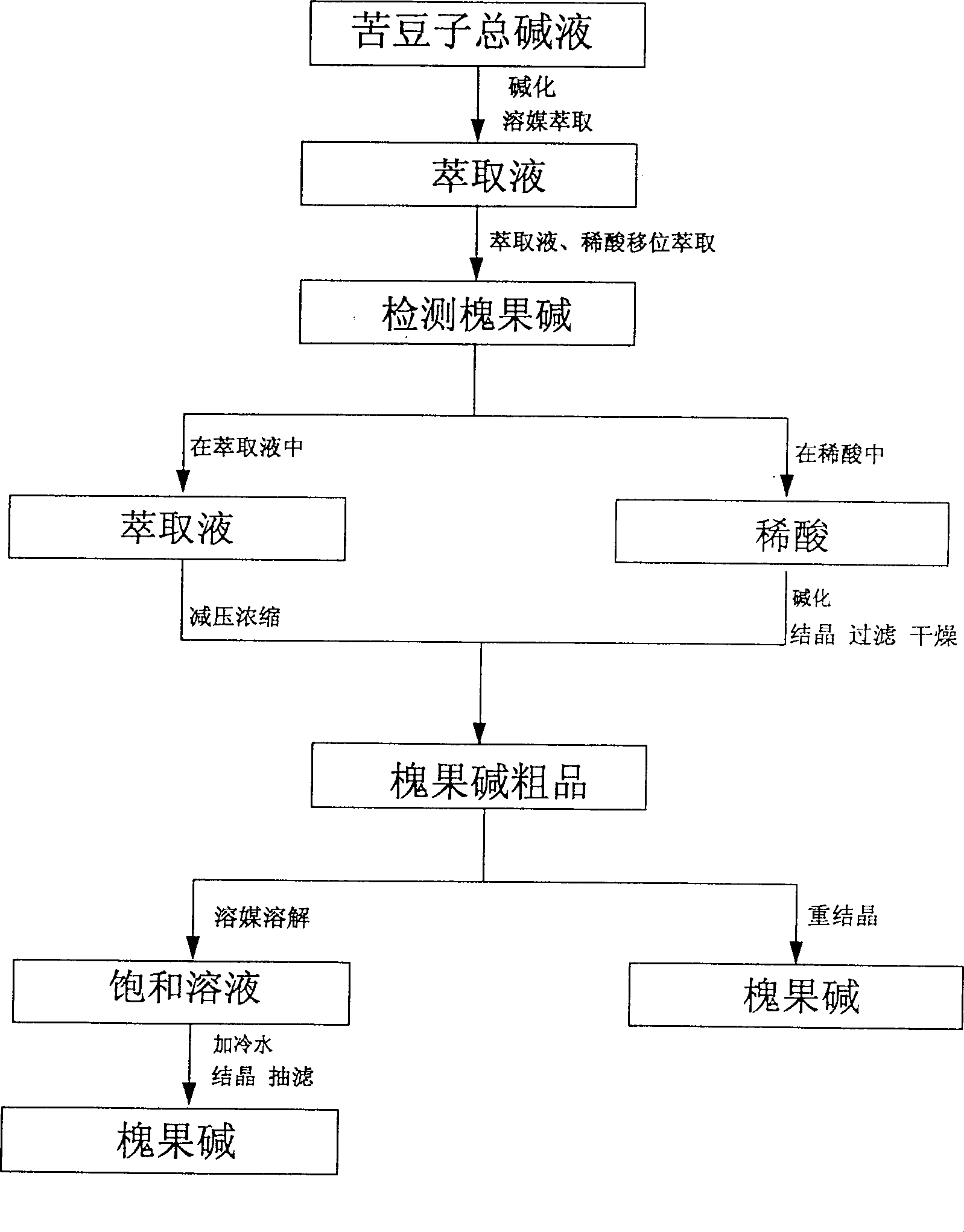

Image

Examples

Embodiment 1

[0028] Total lye 125kg, alkalized with industrial NaOH to above PH12, benzene extraction 4-5 times, combined extracts, extracts and hydrochloric acid shift extraction, first extracted with 10kg of 5% hydrochloric acid, then with 10kg of 10% hydrochloric acid, and then with 10kg10 % Hydrochloric acid extraction, use thin layer chromatography to check that this part of the alkaloid is mainly sophocarpine. Through detection, if sophocarpine is in hydrochloric acid, the hydrochloric acid is adjusted to PH=9 with ARNaOH, crystals are precipitated, filtered, and dried to obtain crude sophocarpine. If it is detected that sophocarpine is in the extract, the extract is concentrated under reduced pressure to obtain 8 kg of crude sophocarpine. Recrystallized with ether to obtain 4.5 kg of sophocarpine.

Embodiment 2

[0030] 125kg of total lye, alkalized with industrial KOH to above PH12, extracted 4-5 times with chloroform, combined the extracts, and extracted with sulfuric acid by shifting, extracting with 10kg of 5% sulfuric acid, then with 10kg of 10% sulfuric acid, and then with 10kg10 % Sulfuric acid extraction, use thin-layer chromatography to check that this part of the alkaloid is mainly sophocarpine. Through detection, if sophocarpine is in sulfuric acid, the sulfuric acid is adjusted to PH=9.5 with ARNaOH, crystals are precipitated, filtered, and dried to obtain crude sophocarpine. If it is detected that sophocarpine is in the extract, the extract is concentrated under reduced pressure to obtain 8 kg of crude sophocarpine. Dissolve the crude sophocarpine in ethanol to make a hot saturated solution, stir and add 3 times the amount of cold water to precipitate white crystals, and then suction and filter to obtain 4.5 kg of sophocarpine.

Embodiment 3

[0032] 125kg of total lye, alkalized with industrial NaOH to above PH12, extracted 4-5 times with ether, combined the extracts, and extracted with phosphoric acid by shifting, extracting with 10kg of 5% phosphoric acid, then with 10kg of 10% phosphoric acid, and then with 10kg10 % Phosphoric acid extraction, use thin layer chromatography to check that this part of the alkaloid is mainly sophocarpine. Through testing, if sophocarpine is in phosphoric acid, the phosphoric acid is adjusted to PH=9.5 with ARNaOH, crystals are precipitated, filtered, and dried to obtain crude sophocarpine. If it is detected that sophocarpine is in the extract, the extract is concentrated under reduced pressure to obtain 8 kg of crude sophocarpine. Dissolve the crude sophocarpine in acetone to make a hot saturated solution, stir and add 4 times the amount of cold water to precipitate white crystals, and then suction and filter to obtain 4.5 kg of sophocarpine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com