Warehousing shelf and warehousing storage applying same

A storage rack and storage rack technology, applied in the field of warehousing and logistics, can solve the problems that logistics vehicles are prone to failure and need maintenance when climbing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

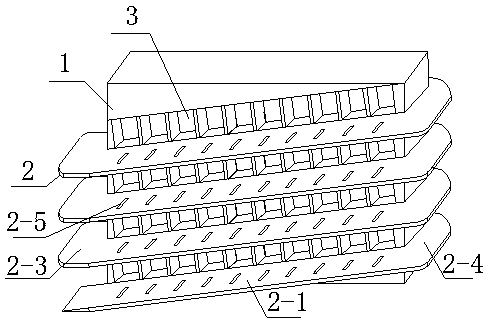

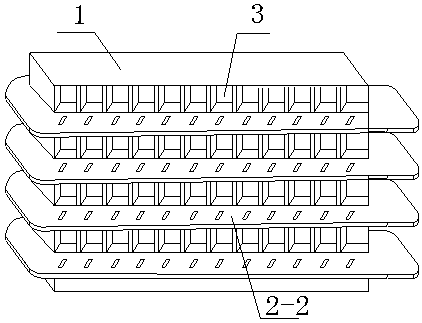

[0043] Such as figure 1 , figure 2 As shown, a storage rack includes a storage rack body 1 and a spirally upward aisle 2 around the storage rack body 1 , and several storage compartments 3 are arranged on the front and rear end surfaces of the storage rack body 1 at positions matching the aisle 2 .

[0044] The cross-section of the storage rack body 1 is square. In the aisle 2, the front aisle 2-1 located at the front end of the storage rack body 1 is inclined upward, and the rear aisle 2-2 located at the rear end of the storage rack body 1 is located at the storage rack body. Both the left aisle 2-3 on the left end surface of the rack body 1 and the right aisle 2-4 on the right end surface of the storage rack body 1 are horizontal.

[0045] A locator 2-5 is provided at a position corresponding to the storage compartment 3 on the aisle 2 .

[0046] The storage rack of this embodiment is designed with a winding aisle, and the vertical track is cancelled. The starting point i...

Embodiment 2

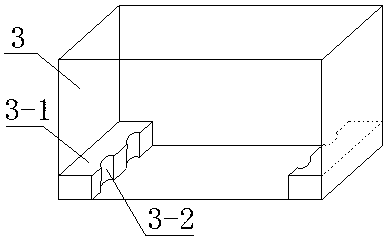

[0051] Such as image 3 In this embodiment, on the basis of Embodiment 1, the device is respectively provided with a grid squat 3-1 on both sides of the storage compartment 3, and two grid squats 3-1 of the same storage compartment 3 are provided with One-to-one correspondence with the fixing slots 3-2.

[0052] In this embodiment, there are two fixing grooves 3-2 inside the grid squat 3-1, and the fixing grooves 3-2 on the two grid squats 3-1 of the same storage grid 3 correspond one-to-one, and correspond to the fixing grooves 3-2 The connecting line is parallel to the outer aisle 2 of the storage compartment 3. The logistics vehicle is also equipped with four wheels. The height of the wheels is higher than the grid squat 3-1, that is, the car body is lifted, so that the wheels can be parallel to the grid squat and close to the grid squat to drive into the storage compartment 3, and the logistics vehicle enters the storage compartment 3 Inside, the four wheels correspond t...

Embodiment 3

[0055] Such as Figure 4 In this embodiment, on the basis of Embodiment 2, the storage compartments 3 of the device are arranged in sequence and at equal intervals along the extension direction of the aisle 2, and there are only compartments 3-1 between adjacent storage compartments 3 .

[0056] This embodiment is mainly to cancel the partition wall between the storage compartments 3, and there is a grid squatting 3-1 between adjacent storage compartments, which is mainly used for the use of combinable logistics vehicles, such as two or more logistics vehicles Combined into a longer logistics cart, it can be used for larger items, or for items that are not easy to store separately. The longer logistics vehicle also finds its way, arrives outside the allocated storage compartment 3, and turns to drive into the corresponding storage compartment 3 in the same way, because there is only a 3-1 separation of grids, there is no obstacle to the logistics vehicle. Two adjacent storage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com