Slideable lifting appliance

A spreader and sliding technology, which is applied in the direction of load hanging components, hoisting equipment braking devices, bottom support structures, etc., can solve the problems of short sliding distance, short sliding stroke of oil cylinder and oil cylinder, frequent maintenance of steel wire rope, etc., to achieve Avoid maintenance, increase distance, and slide easily and flexibly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

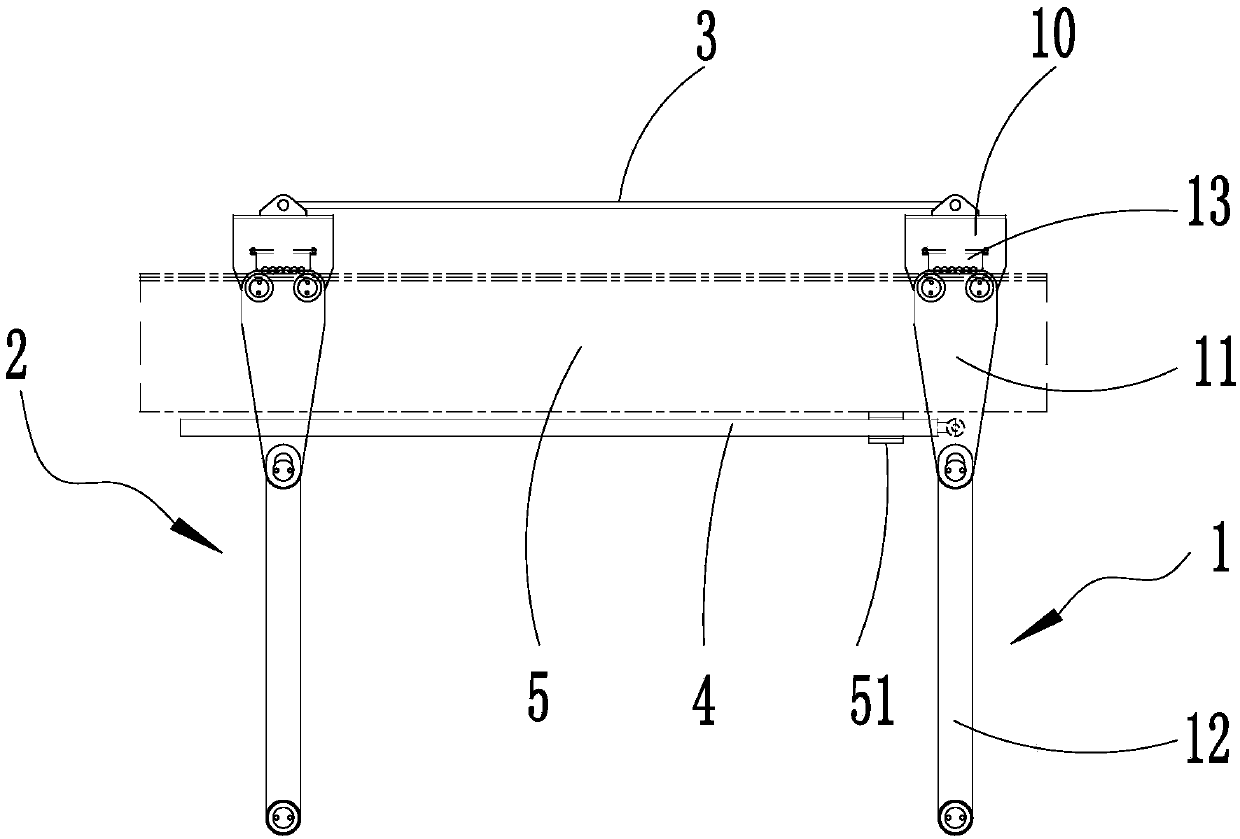

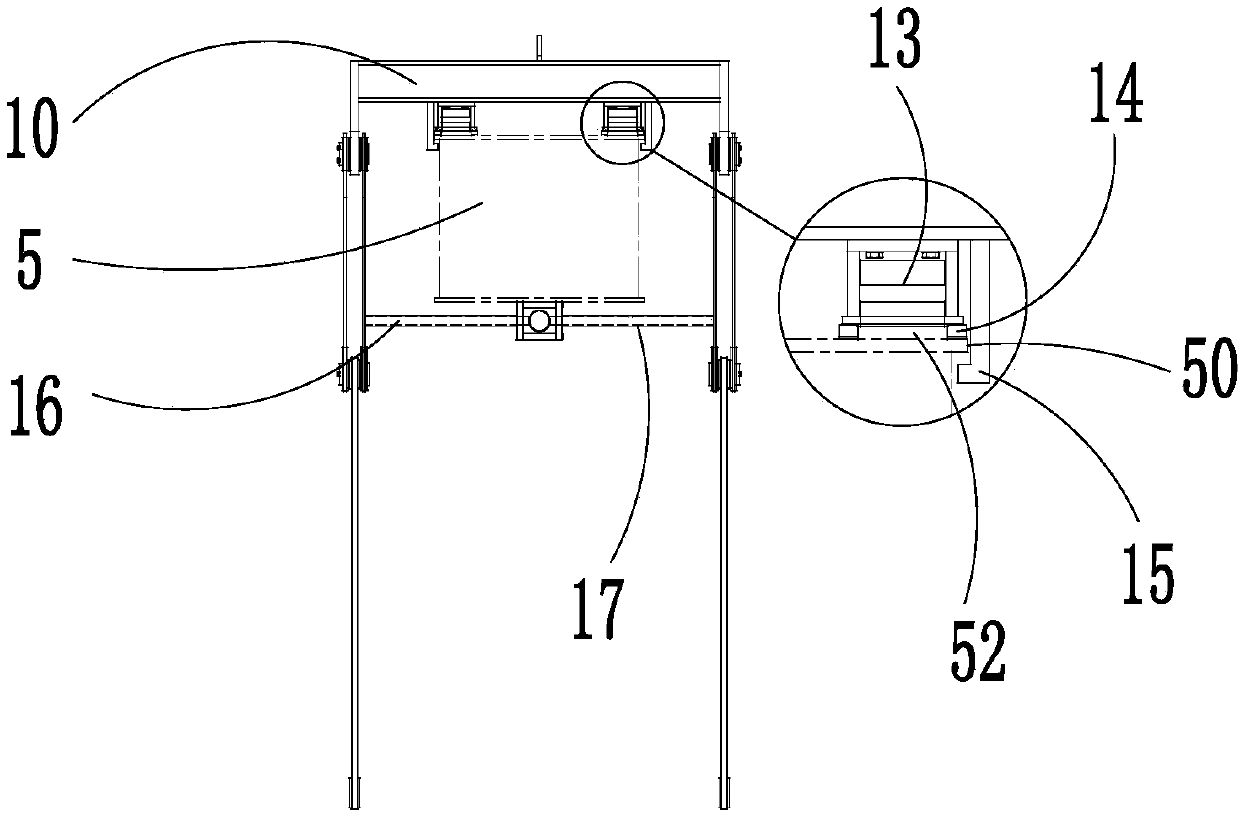

[0025] As shown in the figure, a slidable spreader includes an active spreader 1, a driven spreader 2 connected with the active spreader 1, and a power component for driving the active spreader 1 to slide. Active spreader 1 and driven spreader 2 are connected through connecting rod 3 .

[0026] In this embodiment: the active spreader 1 includes a fixed frame 10, a suspension plate assembly connected to the fixed frame 10, and a rolling assembly connected to the bottom of the fixed frame 10. The lower part of the rolling assembly and the upper part of the power part are formed for the beam to pass through. space, that is to say: when the slidable spreader is installed on the beam 5, the rolling assembly is arranged above the beam 5, and the power part is located below the beam 5.

[0027] There are two sets of hanging plate assemblies, and the two sets of han...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com