A kind of carbon nanotube modified low-temperature solder and its preparation method

A carbon nanotube modification and low-temperature solder technology, which is applied in welding equipment, welding/cutting media/materials, manufacturing tools, etc., can solve the problems of high specific surface energy, poor interface bonding, and difficult dispersion of carbon nanotubes, and achieve Effect of improving drop toughness, improving drop toughness, and enhancing dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

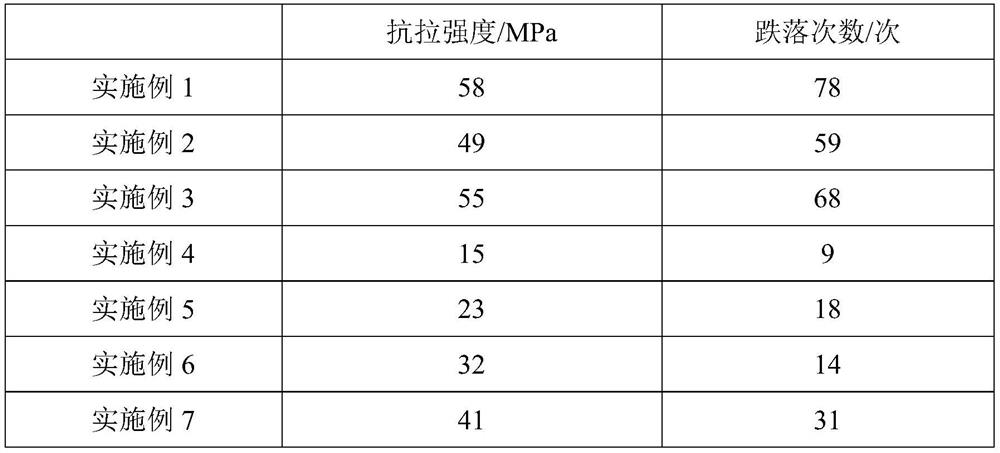

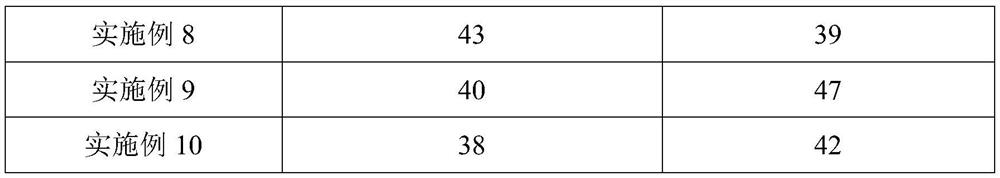

Examples

preparation example Construction

[0048] Among the present invention, the preparation method of described modified carbon nanotubes comprises the following steps:

[0049] (1) Acidified carbon nanotubes: Add carbon nanotubes to the mixed acid solution, ultrasonically treat for 2-4h, stir at 50-70°C for 1-3h, and cool to room temperature naturally; after centrifugation, wash with water several times to the lotion The pH value is 7, filtered and dried to obtain acidified carbon nanotubes;

[0050] (2) Activation of carbon nanotubes: Add the acidified nanotubes into the sensitization solution, stir for 20-40min, centrifuge and wash with water several times until the pH value of the washing solution is 7 to obtain sensitized carbon nanotubes; then sensitized carbon nanotubes Add activation solution to the tube, stir for 20-40min, centrifuge and wash with water for several times until the pH of the washing solution is 7, filter and dry to obtain activated carbon nanotubes;

[0051] (3) Electroplating carbon nanotu...

Embodiment 1

[0081] Embodiment 1 provides a carbon nanotube-modified low-temperature solder, which includes the following components by weight percentage: 3% nickel-plated carbon nanotubes, 4.5% hydroxyl multi-walled carbon nanotubes, 3% modified carbon nanotubes, The balance is tin-bismuth series alloy; the weight ratio of nickel-plated carbon nanotubes and hydroxyl multi-walled carbon nanotubes is 1:1.5; the weight ratio of nickel-plated carbon nanotubes and modified carbon nanotubes is 1:1 .

[0082] The nickel-coated carbon nanotubes have a length of 20±10 μm, a diameter of 25±5 nm, and a nickel content of 60%. They were purchased from Beijing Deke Daojin Technology Co., Ltd., model CNT805.

[0083] The tin-bismuth series alloy is Sn42Bi58, purchased from Nangong Zhuyu Alloy Materials Co., Ltd.

[0084] The hydroxyl multi-walled carbon nanotubes have a length of 20±10 μm, a tube diameter of less than 8 nm, and a hydroxyl content of 5.58%. They were purchased from Beijing Deke Daojin T...

Embodiment 2

[0093] Embodiment 2 provides a carbon nanotube-modified low-temperature solder, which includes the following components by weight percentage: 0.05% nickel-plated carbon nanotubes, 0.005% of hydroxyl multi-walled carbon nanotubes, 0.025% of modified carbon nanotubes, The balance is tin-bismuth series alloy; the weight ratio of nickel-plated carbon nanotubes and hydroxyl multi-walled carbon nanotubes is 1:0.1; the weight ratio of nickel-plated carbon nanotubes and modified carbon nanotubes is 1:0.5 .

[0094] The nickel-coated carbon nanotubes have a length of 20±10 μm, a diameter of 25±5 nm, and a nickel content of 60%. They were purchased from Beijing Deke Daojin Technology Co., Ltd., model CNT805.

[0095] The tin-bismuth series alloy is Sn42Bi58, purchased from Nangong Zhuyu Alloy Materials Co., Ltd.

[0096] The hydroxyl multi-walled carbon nanotubes have a length of 20±10 μm, a tube diameter of less than 8 nm, and a hydroxyl content of 5.58%. They were purchased from Beij...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com