Deep-hole numerical control fine cold-welding equipment

A cold welding and fine technology, applied in welding equipment, arc welding equipment, metal processing equipment, etc., can solve problems such as non-concentricity, and achieve the effect of stable welding formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions of the present invention will be further described in detail below through specific implementations.

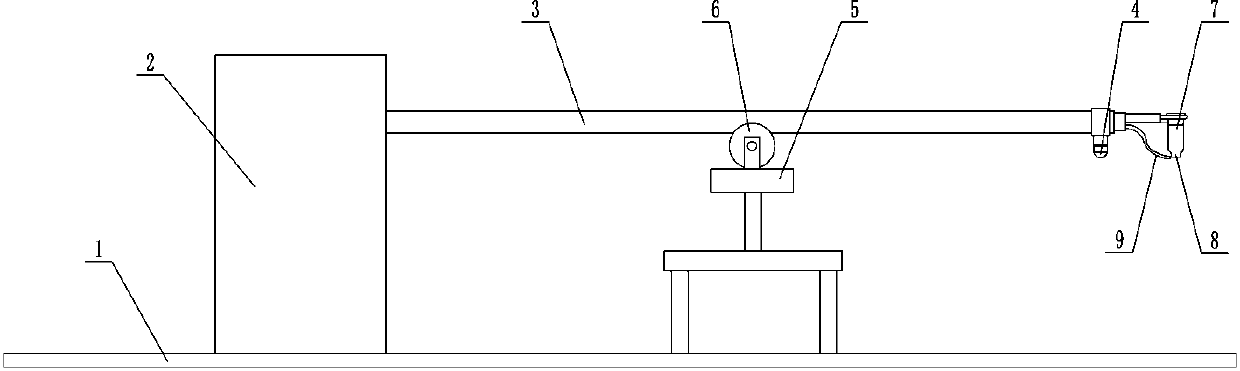

[0020] Such as figure 1 As shown, a deep-hole numerical control precision cold welding equipment includes a welding machine track 1, a welding machine 2, a long rod welding torch 3, a self-calibrating fixed distance rod 4, and a lifting gun frame 5. The welding machine 2 runs on the welding machine On track 1, its walking process is controlled by a program, and the welding speed is used to control the progress of deep hole welding in the depth direction.

[0021] The welding machine 2 is connected to one end of the long rod welding torch 3, the lifting gun holder 5 is used to lift the long rod welding torch 3, the lifting type gun holder can use a hydraulic support, a pneumatic support or a screw support, the lifting type gun A passive top wheel 6 is installed on the top of the frame 5. The top wheel 6 is provided with a U-shaped groove or a groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com