Cerium-based ozone catalyst containing double active sites as well as preparation method and application thereof

A catalyst and dual-activity technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as narrow pH range, low organic mineralization performance, and easy loss of active components. Achieve the effect of small size, promote cracking and decarboxylation mineralization, and good mineralization enhancement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Ce-g-C 3 N 4 Catalyst preparation:

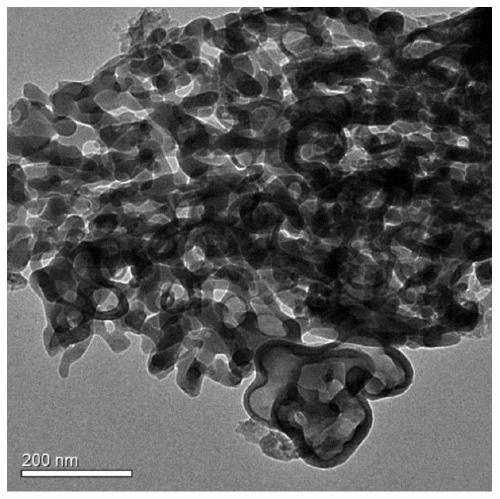

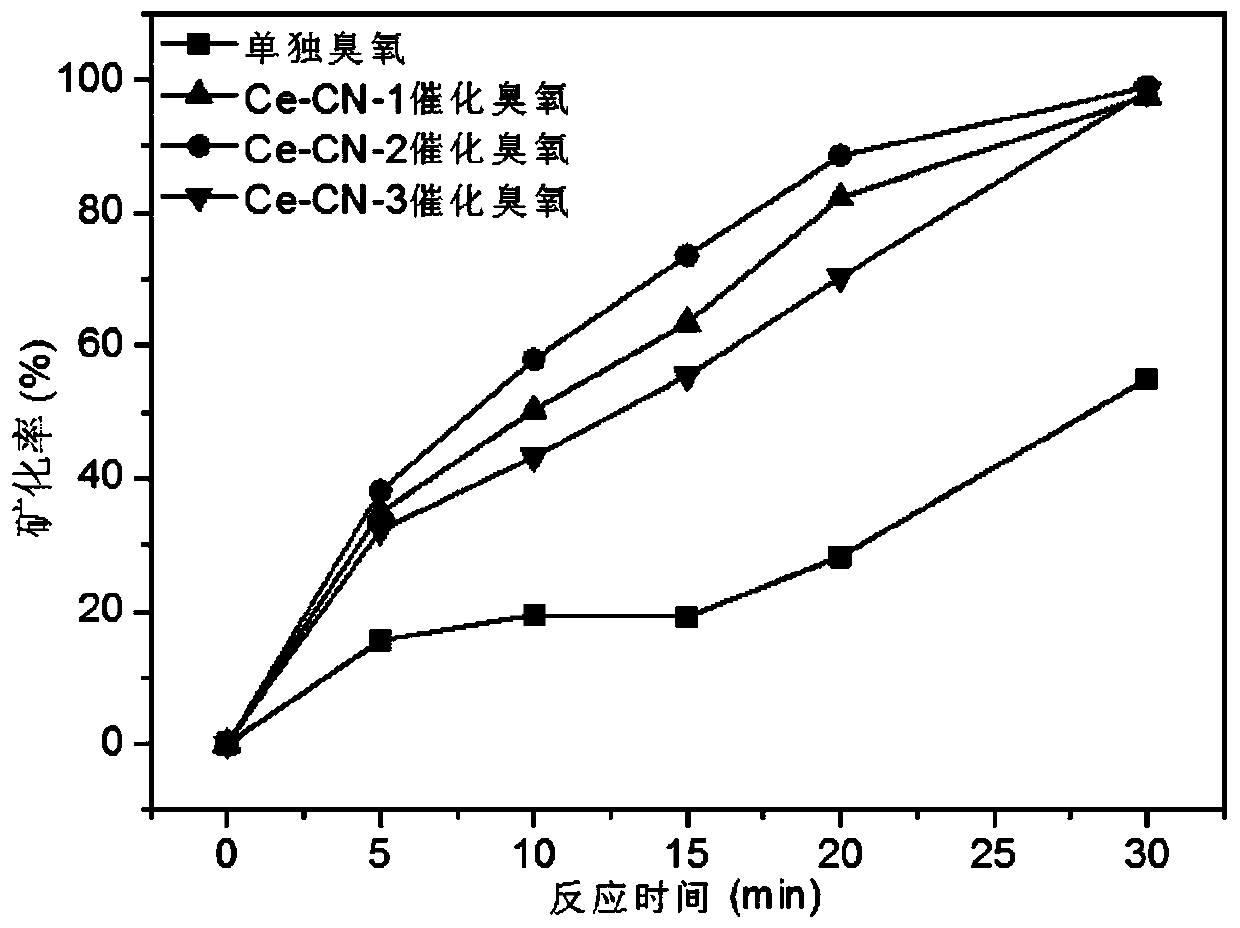

[0043] Melamine powder was dissolved in 100mL boiling water to make a melamine solution with a concentration of 0.5mol / L; 1.0gCe(NO 3 ) 3 ·6H 2 O powder was added to the melamine solution with a concentration of 0.5mol / L, then 15g of gluconic acid and 5mL of 37wt% hydrochloric acid were added, and mechanically stirred in a constant temperature water bath at 100°C for 30min; the mixture obtained after mechanical stirring was dried at 60°C for 8h; The final solid was calcined at 450 °C for 1 h in a tube furnace with a nitrogen flow rate of 50 mL / min to obtain Ce-g-C 3 N 4 The catalyst material is named Ce-CN-1. Its TEM image is shown in figure 1 , the catalyst is a layered stacked structure with a size of about 100nm.

Embodiment 2

[0045] Ce-g-C 3 N 4 Catalyst preparation:

[0046] Melamine powder was dissolved in 100mL boiling water to make a melamine solution with a concentration of 5mol / L; 0.1gCe(NO 3 ) 3 ·6H 2 O powder was added to the melamine solution with a concentration of 5mol / L, then 10g of ascorbic acid and 5mL of 37wt% hydrochloric acid were added, and mechanically stirred in a constant temperature water bath at 100°C for 30min; the mixture obtained after mechanical stirring was dried at 100°C for 12h; after drying, the solid Calcined at 500 °C for 2 h in a tube furnace with a nitrogen flow rate of 100 mL / min to obtain Ce-g-C 3 N 4 The catalyst material is named Ce-CN-2.

Embodiment 3

[0048] Ce-g-C 3 N 4 Catalyst preparation:

[0049] Melamine powder was dissolved in 100mL boiling water to make a melamine solution with a concentration of 2mol / L; 0.5gCe(NO 3 ) 3 ·6H 2 O powder was added to the melamine solution with a concentration of 2mol / L, then 20g of citric acid and 5mL of 37wt% hydrochloric acid were added, and mechanically stirred in a constant temperature water bath at 100°C for 30min; the mixture obtained after mechanical stirring was dried at 80°C for 10h; after drying The solid was calcined at 550 °C for 1.5 h in a tube furnace with a nitrogen flow rate of 150 mL / min to obtain Ce-g-C 3 N 4 The catalyst material is named Ce-CN-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com