A method for assembling small-scale drilling equipment for climbing slopes

A technology of drilling equipment and assembly method, applied in drilling equipment and methods, drilling equipment, drilling tools, etc., can solve problems such as single fixed structure, inability to adapt to complex site conditions, and vibration of drill pipes up and down.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

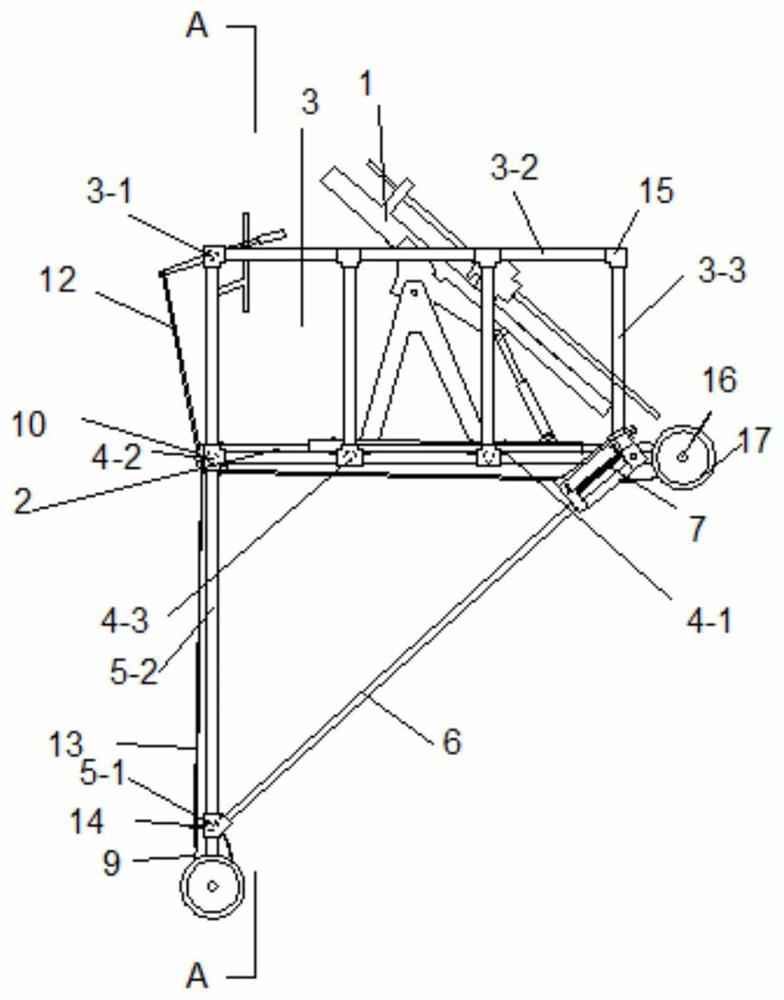

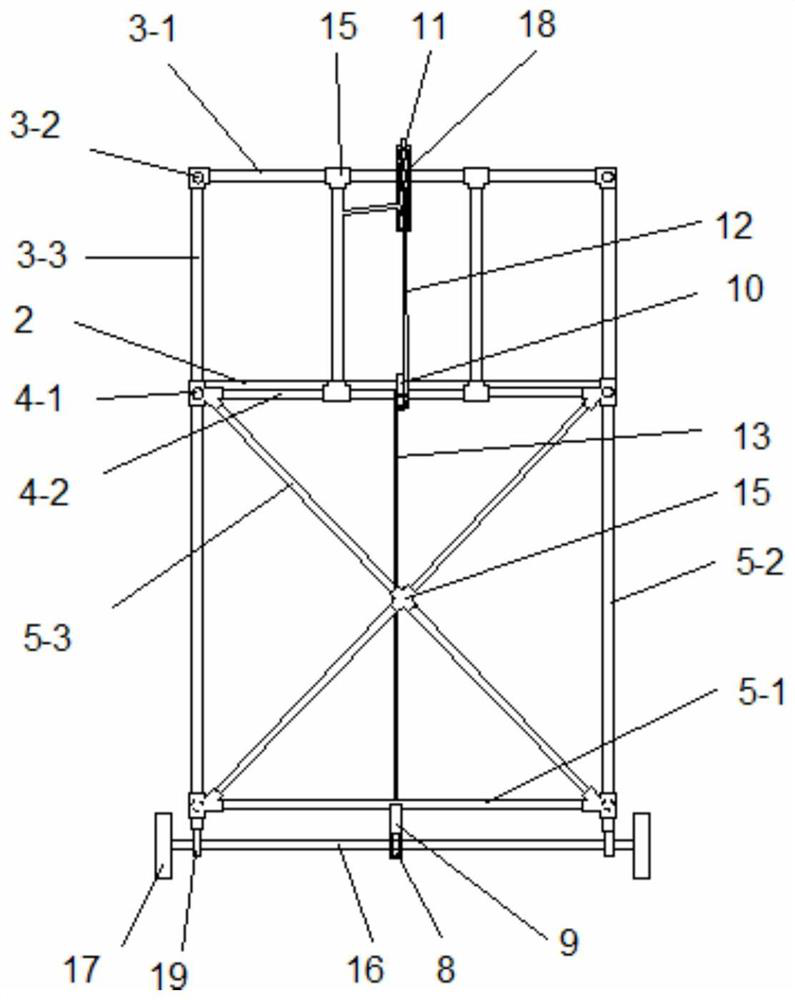

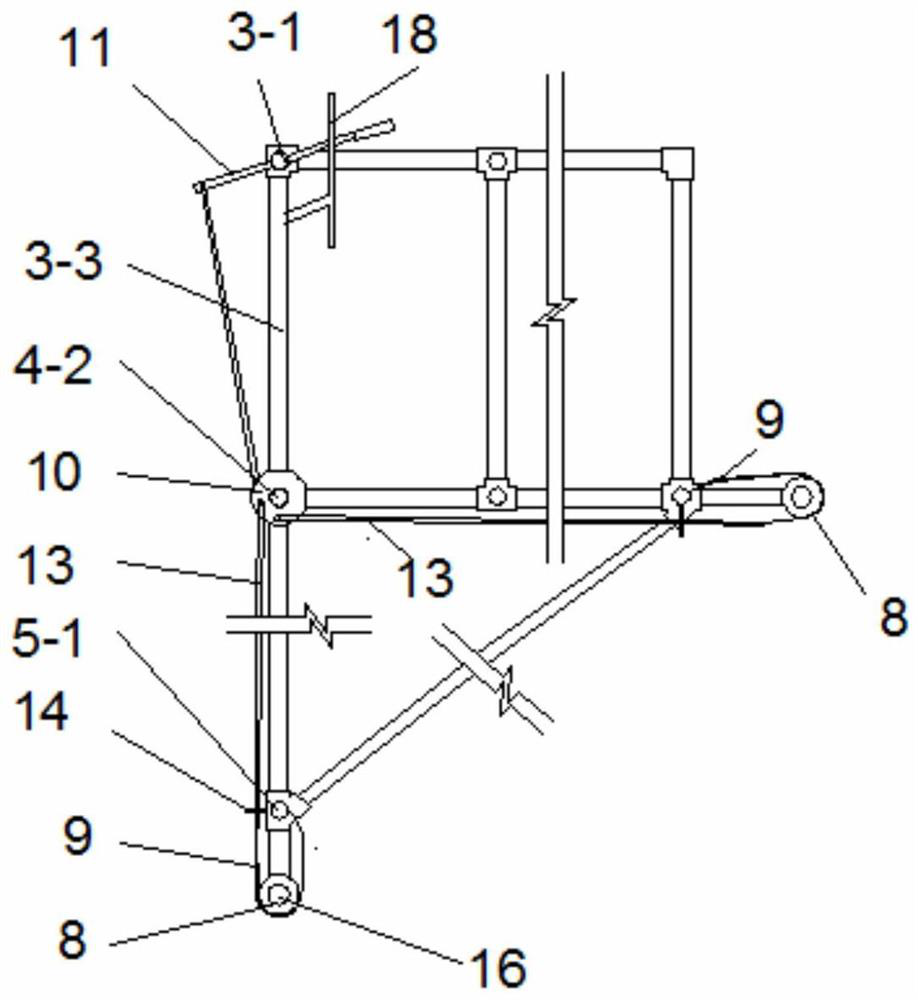

[0033] A small drilling equipment for climbing slopes, comprising a climbing trolley and a suspension device 7, the climbing trolley includes a vehicle frame, a braking system, a front coupling wheel and a rear coupling wheel, the vehicle frame It is a triangular prism support structure, including a horizontal support, a vertical support and a chassis. An operating platform 2 is arranged on the horizontal support. A bolter rig 1 is installed on the operating platform 2, and a fence 3 is installed around the operating platform 2. Fence 3 comprises two parallel longitudinal steel pipes 3-2, two parallel horizontal steel pipes 3-1 and several vertical steel pipes 3-3, longitudinal steel pipes 3-2, horizontal steel pipes 3-1 and vertical steel pipes 3-3 Assembled into a fence 3 through fasteners 15; the horizontal support includes two parallel longitudinal beams 4-1, a front beam 4-2, several middle beams 4-3 and a rear beam, the longitudinal beam 4-1, the front beam The upper bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com