Color-selectable nylon composite material for laser welding and preparation method thereof

A nylon composite material, laser welding technology, applied in the field of color selectable, nylon composite material for laser welding and its preparation, to achieve the effect of increasing the application field, high absorption efficiency, and changing limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

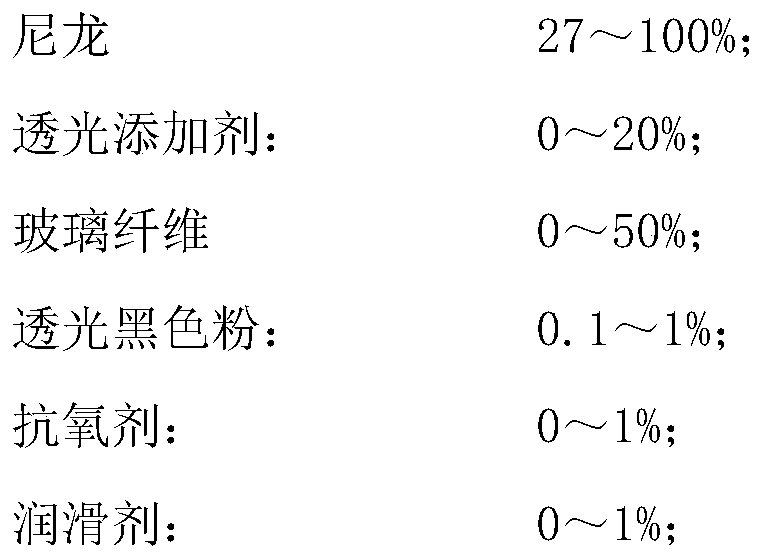

[0049] Translucent components:

[0050] Weigh PA6 5.87kg, bake at 100°C for 4 hours, PA6I 1.0kg, light-transmitting black powder 50g, lubricant 50g, antioxidant 30g, mix well in a high-speed mixer to obtain a resin mixture, set aside;

[0051] Weigh 3.0 kg of glass fiber and set aside.

[0052] Above-mentioned resin mixture is joined in the twin-screw extruder (screw diameter is 35mm, length-to-diameter ratio is L / D=40) through main feeding port, glass fiber is added into twin-screw extruder through side feeding port, double The control temperature of each section of the screw extruder (from the feeding port to the nozzle outlet) is 180°C, 210°C, 225°C, 225°C, 215°C, 210°C, 210°C, 210°C, 210°C, 210°C, 210°C ℃, 210 ℃, the twin-screw extruder speed is set to 480r / min, the strips are cooled in a water tank, dried by a blast dryer, and pelletized by a pelletizer to obtain the product.

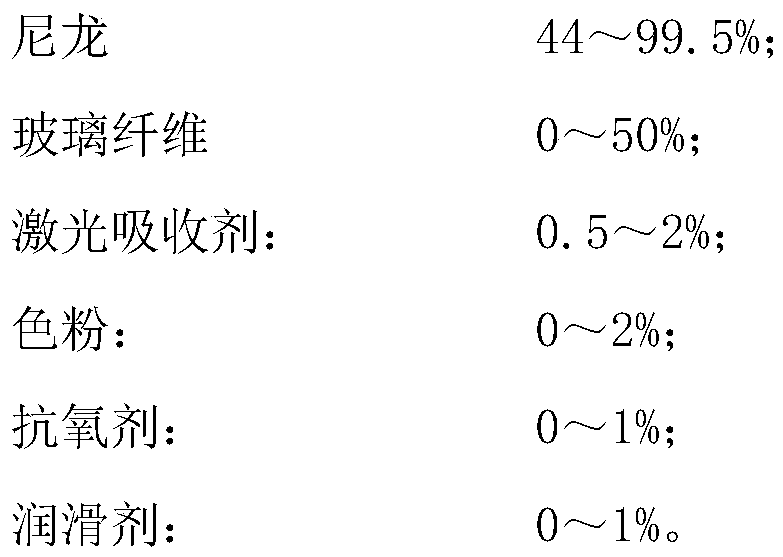

[0053] Absorbing component:

[0054] Weigh 6.87kg of PA6, bake at 100°C for 4 hours, add 50g...

Embodiment 2

[0059] Translucent components:

[0060] Weigh 5.87kg of PA66, bake at 100°C for 4 hours, PA6I 1.0kg, 50g of translucent black powder, 50g of lubricant, and 30g of antioxidant, mix them evenly in a high-speed mixer to obtain a resin mixture, and set aside;

[0061] Weigh 3.0 kg of glass fiber and set aside.

[0062] Above-mentioned resin mixture is joined in the twin-screw extruder (screw diameter is 35mm, length-to-diameter ratio is L / D=40) through main feeding port, glass fiber is added into twin-screw extruder through side feeding port, double The control temperature of each section of the screw extruder (from the feeding port to the nozzle outlet) is 210°C, 240°C, 265°C, 265°C, 255°C, 240°C, 240°C, 240°C, 240°C, 240°C, 240°C ℃, 240 ℃, the twin-screw extruder speed is set to 480r / min, the strips are cooled in a water tank, dried by a blast dryer, and pelletized by a pelletizer to obtain the product.

[0063] Absorbing component:

[0064] Weigh 6.87kg of PA66, bake the mat...

Embodiment 3

[0069] Translucent components:

[0070] Weigh 5.87kg of PA6 / 66, bake at 100°C for 4 hours, PA6I 1.0kg, 50g of translucent black powder, 50g of lubricant, 30g of antioxidant, mix them evenly in a high-speed mixer to obtain a resin mixture, and set aside;

[0071] Weigh 3.0 kg of glass fiber and set aside.

[0072] Above-mentioned resin mixture is joined in the twin-screw extruder (screw diameter is 35mm, length-to-diameter ratio is L / D=40) through main feeding port, glass fiber is added into twin-screw extruder through side feeding port, double The control temperature of each section of the screw extruder (from the feeding port to the nozzle outlet) is 180°C, 210°C, 225°C, 225°C, 215°C, 210°C, 210°C, 210°C, 210°C, 210°C, 210°C ℃, 210 ℃, the twin-screw extruder speed is set to 480r / min, the strips are cooled in a water tank, dried by a blast dryer, and pelletized by a pelletizer to obtain the product.

[0073] Absorbing component:

[0074] Weigh 6.87kg of PA6 / 66, bake the mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com