Synthesis method of cyclobutanone

A synthesis method and technology of cyclobutanone, which are applied in chemical instruments and methods, preparation of carbon-based compounds, preparation of hydroxyl compounds, etc., can solve problems such as affecting the use of cyclobutanone and being difficult to separate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Unless otherwise specified, the experimental methods used in the following examples are conventional methods, and those of ordinary skill in the art can choose other commonly used methods in the art to replace the specification on the basis of the disclosure of the present invention.

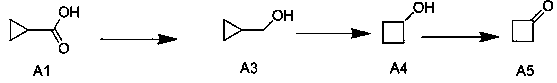

[0031] The present invention discloses a kind of synthetic method of cyclobutanone, and its reaction formula is as follows:

[0032]

[0033] Add 300g of raw material A1 and 1.5L of methyl tert-butyl ether into a cleaned and dried 5L kettle. After the system is dissolved, cool down to 0°C with an ice-water bath, and add 131.9g of sodium borohydride in batches, (about 15g per batch ), at the beginning the system exothermic and degassed obviously, and the internal temperature rose up to 40°C; the system continued to control the temperature dropwise, and the system exothermed obviously, and the maximum did not exceed 50°C. Dilute, and then adjust the pH to be weakly alkaline (pH 8-9), GC ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com