Graphene heat dissipation film and preparation method thereof

A technology of graphene heat dissipation film and graphene, which is applied in the field of graphene heat dissipation film and its preparation, can solve the problems of complex preparation process of graphene heat dissipation film for mobile phones, poor quality of graphene oxide raw materials, and reduced performance of graphene heat dissipation film. Ease of large-scale production and application, low price, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

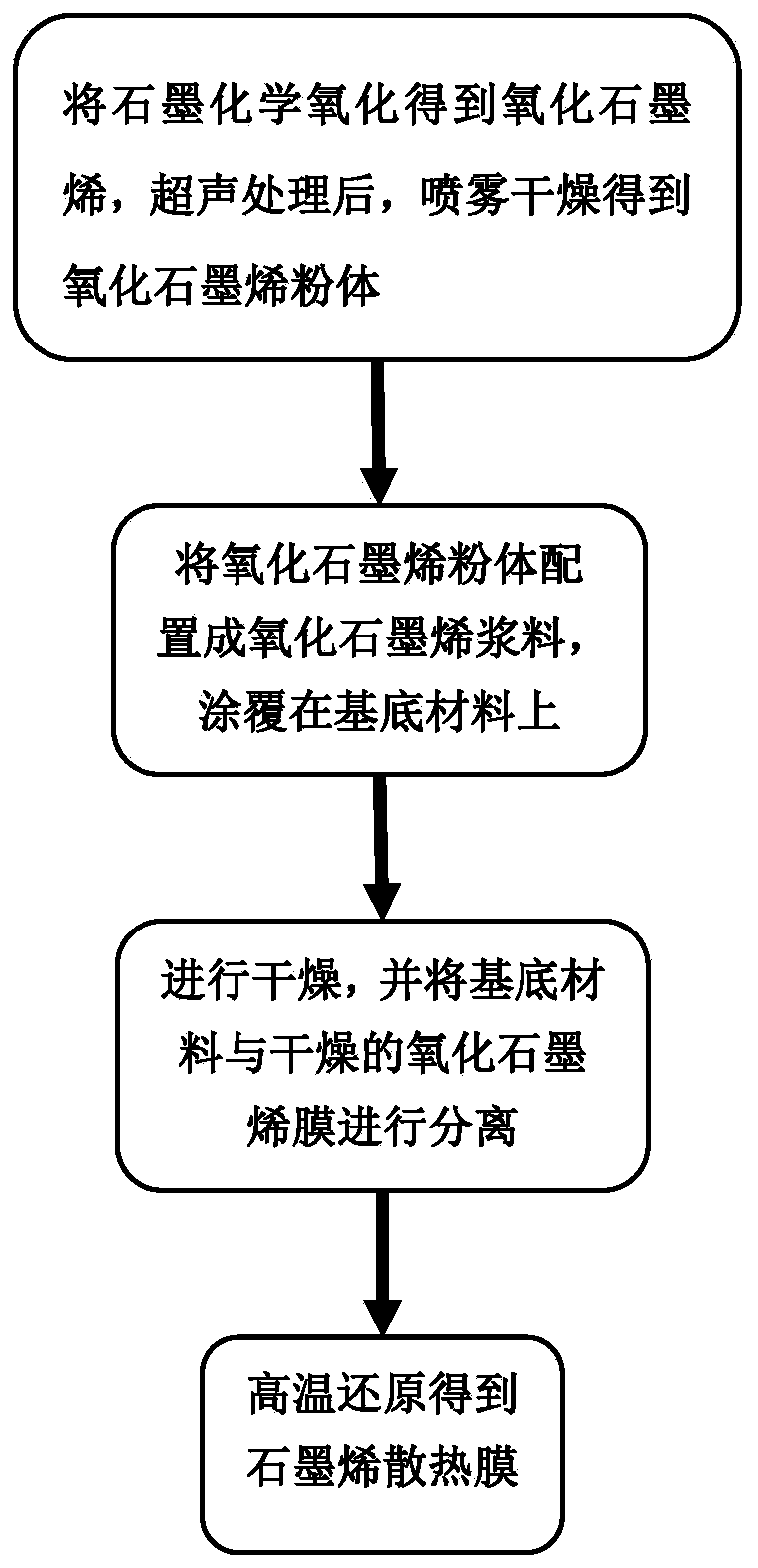

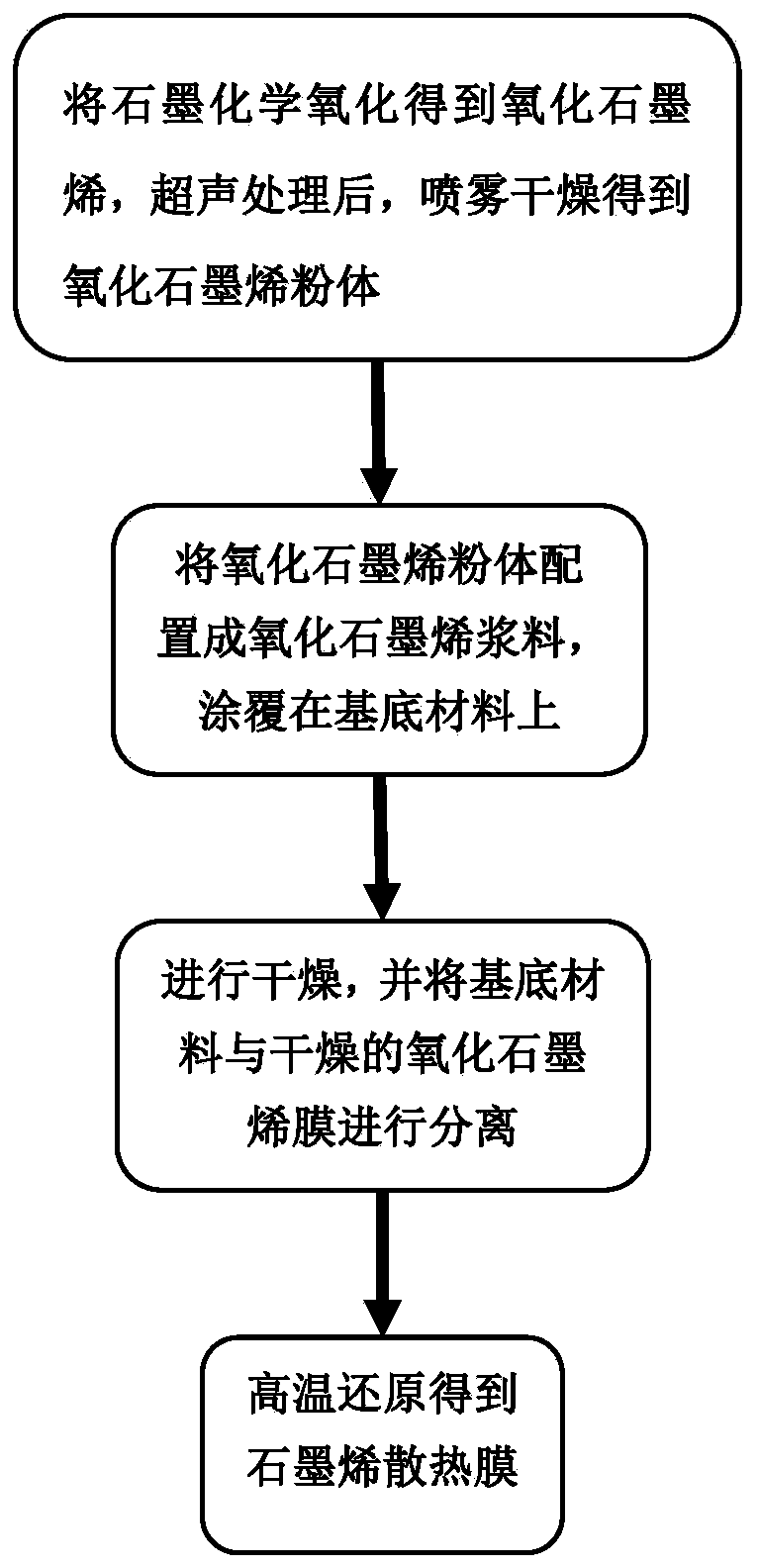

[0037] See figure 1 The preparation method of the graphene loose film of the present invention includes the following four steps: In the first step, the flake graphite is chemically oxidized with bismuth salt under strong acid conditions, washed to a pH of 5-7, and then subjected to ultrasonic treatment to obtain oxidation The graphene aqueous dispersion is spray-dried to obtain graphene oxide powder; the second step is to configure the graphene oxide powder into a slurry, and the graphene oxide slurry is coated on the base material; the third step is to The base material coated with the graphene oxide slurry is dried, and the base material is separated from the dried graphene oxide film; the fourth step is to reduce the dried graphene oxide film at high temperature to obtain a graphene heat dissipation film.

[0038] Preferably, in the first step, the water used in the ultrasonic treatment is deionized water or distilled water.

[0039] Preferably, in the first step, the temperatu...

Embodiment 1

[0049] Put 10g flake graphite (600 mesh) into 300mL concentrated sulfuric acid (mass concentration 98%), after mechanical stirring for 30min, put 40g sodium bismuthate at 10℃, stir at 40℃ for 2h, then pour the reaction solution into 300mL. After filtering the ionized water with a ceramic membrane filter device, the obtained solid is washed to a pH of 5-7, and then added to 1000 mL of deionized water and ultrasonically treated for 1 hour to obtain an aqueous dispersion of graphene oxide.

[0050] The above aqueous graphene oxide dispersion is spray-dried at 120° C. to obtain graphene oxide powder. Disperse the graphene oxide powder in deionized water to form a graphene oxide slurry with a solid content of 3%, and apply it on the PET film with a film coater, and dry it in an oven at 50°C for 3 hours. Remove the graphene oxide film and use A graphene heat dissipation film with a thickness of 30 μm was obtained by reducing at a high temperature of 1200°C for 30 minutes.

[0051] The g...

Embodiment 2

[0054] Put 10g flake graphite (1000 mesh) into 300mL concentrated sulfuric acid (mass concentration 98%), after mechanical stirring for 30min, put 40g sodium bismuthate at 10℃, stir at 40℃ for 2h, then pour the reaction solution into 300mL. After filtering the ionized water with a ceramic membrane filter device, the obtained solid is washed to a pH of 5-7, and then added to 1000 mL of deionized water and ultrasonically treated for 1 hour to obtain an aqueous dispersion of graphene oxide.

[0055] The above aqueous graphene oxide dispersion is spray-dried at 120° C. to obtain graphene oxide powder. Disperse the graphene oxide powder in deionized water to form a graphene oxide slurry with a solid content of 3%, and apply it on the PET film with a film coater, and dry it in an oven at 50°C for 3 hours. Remove the graphene oxide film and use Reduced at a high temperature of 1200°C for 30 minutes to obtain a graphene heat dissipation film with a thickness of 33 μm.

[0056] The graphen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com