Connecting rod milling tool and connecting rod milling tool assembly

A technology for milling cutters and connecting rods, which is applied in the direction of milling cutters, manufacturing tools, milling machine equipment, etc. It can solve the problems of difficult size adjustment, affecting production capacity, and failure to meet the normal requirements of the production line. The effect of clamping difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in more detail below in conjunction with the accompanying drawings. It should be noted that the following description of the present invention with reference to the accompanying drawings is only illustrative rather than limiting. Different embodiments can be combined with each other to form other embodiments not shown in the following description.

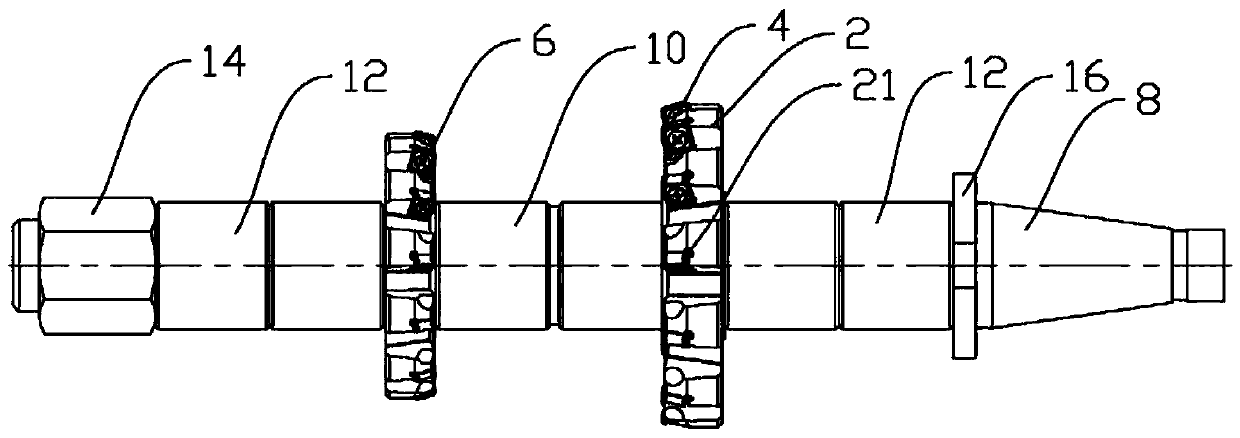

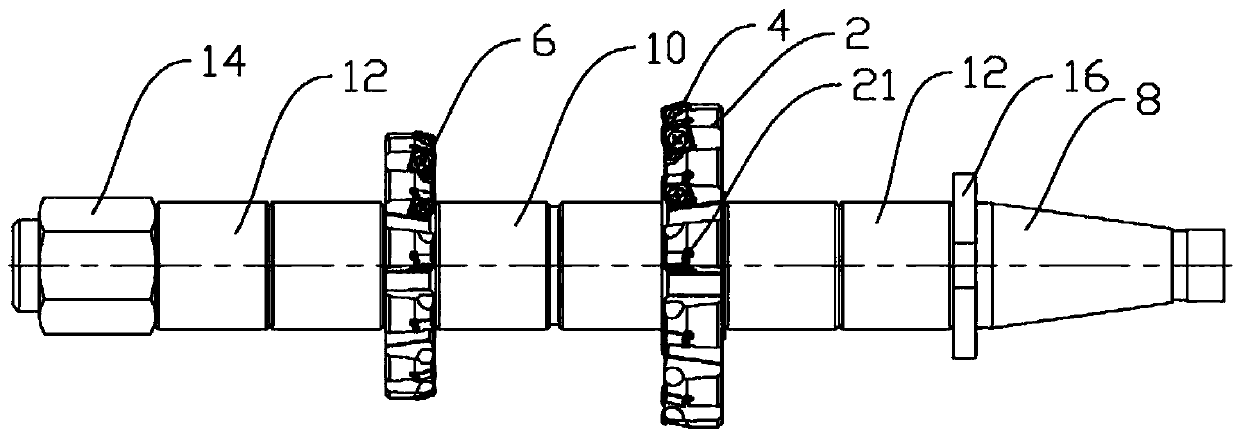

[0019] The invention provides a connecting rod milling tool, referring to figure 1 , the connecting rod milling tool includes a cutter head 2 and a plurality of blades 4, wherein, the cutter head 2 is provided with a plurality of installation positions 21, and the blades 4 are mounted on the installation positions one by one through threads. The present invention improves the cutter head, sets corresponding threaded holes on the cutter head and the blade, fixes and clamps the blade and the cutter head through bolts or screws 6, greatly reduces the difficulty of clamping, and makes the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com