Valve clamping system

A technology of valves and clips, applied in the direction of heart valves, valve rings, etc., can solve the problems of difficult clamping, atrium and chord damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

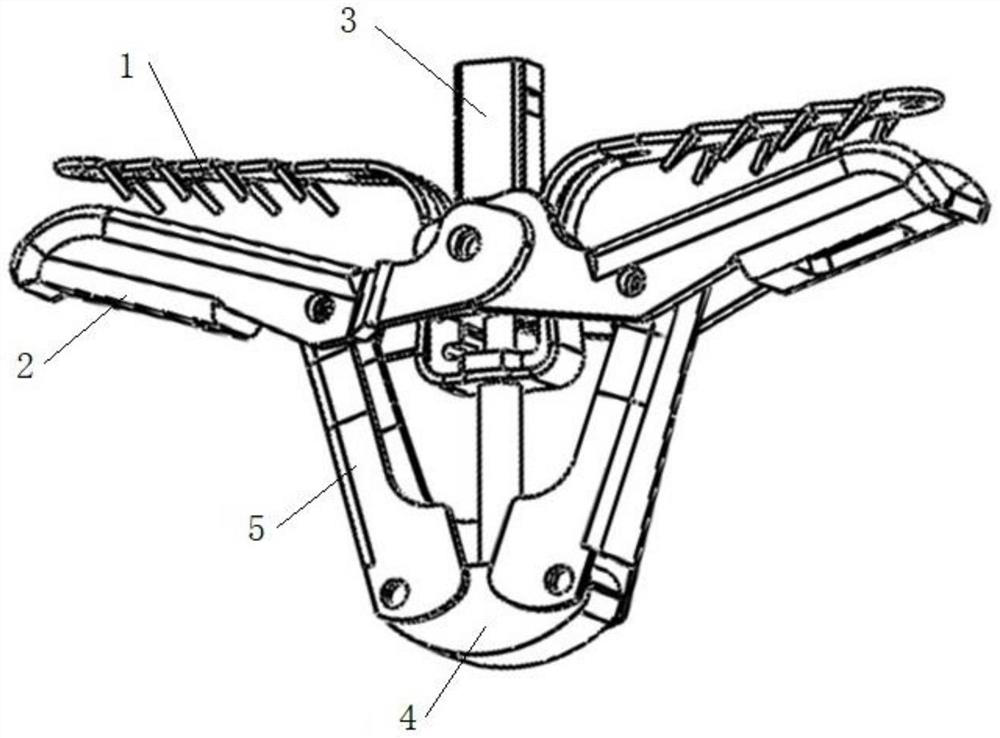

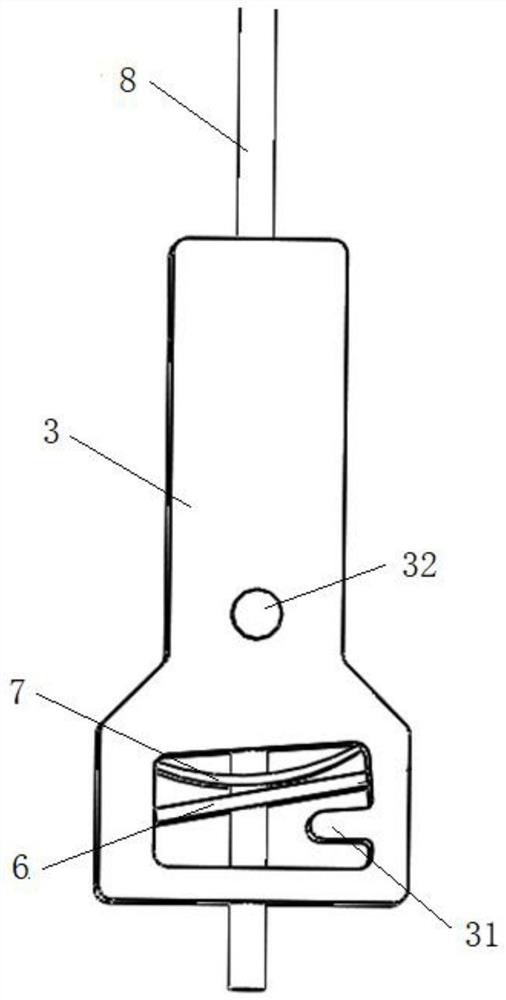

[0036] like Figure 1 to 4 , The present embodiment provides a valve clamping system, comprising an adjustment mechanism and a locking mechanism. Wherein the adjusting mechanism comprises a clip proximal end, the distal end of the clip 2, the center of the base 3 and the base body, a proximal end of the clip the clip base to the central body 3, and the proximal end of the clip 1 has elasticity, the distal end of clip 2 rotatably attached to the central body and the base body base 3, toward or away from the proximal end to a clip, having a central seat body receiving chamber 3, the center of the seat body is provided with drill holes on opposite side walls 3; locking mechanism comprises a fixing piece A6, B7 fixing piece, the push rod 8 and 9 the control member, and a fixing piece fixing piece A6 B7 against each other is provided in the receiving chamber, the push rod 8 is located in receiving chamber and through the fixing piece and the fixing piece A6 B7 is connected to the a base...

Embodiment 2

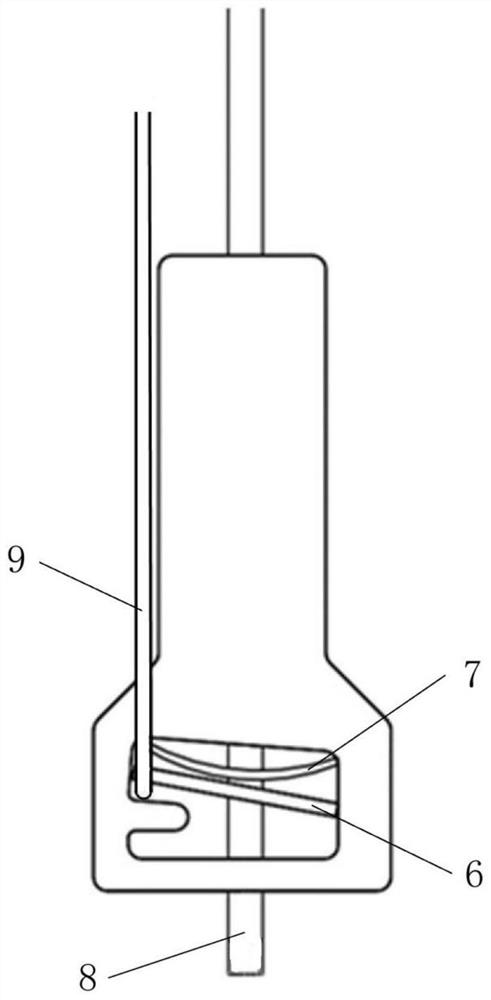

[0053] The present embodiment discloses a clamping system valve, the valve according to the present embodiment a clamping system in the embodiment of the valve clamping system embodiment except that: The Figure 5 with Image 6 , At least a fixing piece of shrapnel B7, B7 fixing piece is configured to cause the fixing piece A6 against the stopper projection 31, and in the first position, the control member 9 away from the stopper projection 31 of a push rod 8 bypassing the side fixing piece and the fixing piece A6 B7, and pulls the control member 9 is not capable of fixing sheet A6 in the first position. Alternatively, the fixing piece and the fixing piece A6 B7 are shrapnel, but when the fixing piece A6 elastic force of gravity and the applied B7 fixing piece, different from the embodiment example 1, such as Figure 5 , In relaxing the control member 9, the fixing piece can not be placed horizontally A6 receiving cavity, but is pressed against the fixing piece B7 first position, whe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wire diameter | aaaaa | aaaaa |

| Maximum radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com