Rotary blowing clamping head for film coating of inner wall of light emitting diode (LED) lamp tube

A technology of LED lamp tube and wall coating film, applied in the direction of coating, device for coating liquid on the surface, pretreatment surface, etc., can solve the problems of stability affecting product quality, shaking of lamp tube, uneven thickness of coating film, etc. , to achieve the effect of stabilizing product quality, designing scientifically, and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

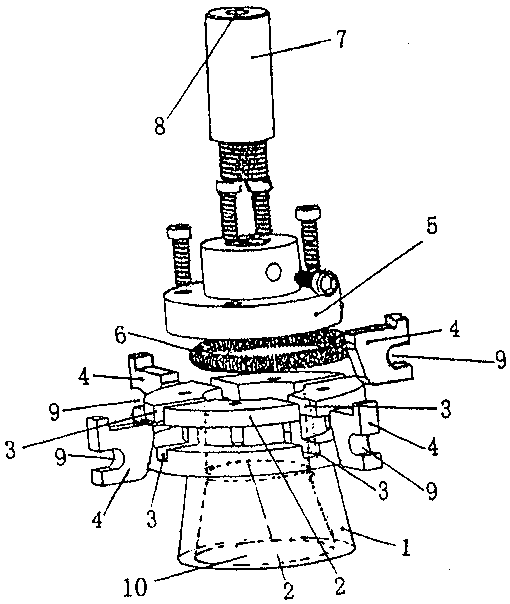

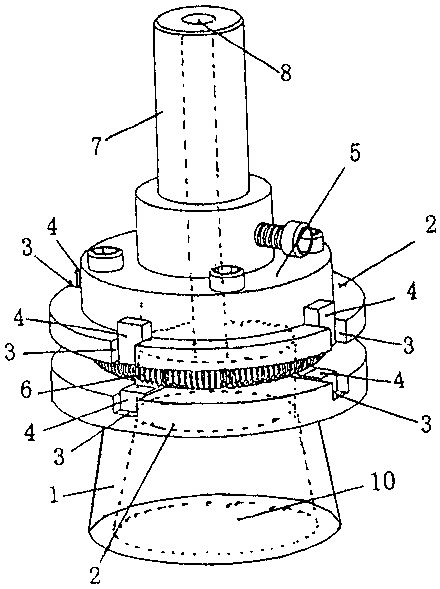

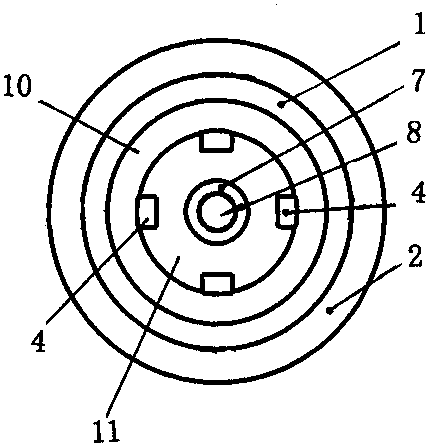

[0013] figure 1 , 2 , shown in 3 and 4: the conical revolving seat 1 that can be inserted into the lamp tube head 12 from the trumpet-shaped opening 10 below is connected with an integrated flange seat 2, and the conical revolving seat is distributed around the flange seat 2 1. There are several chutes 3 connected to the upper pipe head socket 10. Several chute 3s are respectively equipped with sliding claws 4 that can be snapped into the chute 3 and expose the tail end at the pipe head socket 11. Several sliding claws 4 pass through the ring Shaped extension spring 6 is tensioned and positioned in the chute 3, a bolt-fixed flange plate 5 is arranged above the flange seat 2, and a blowing nozzle 7 is screwed on the top of the flange plate 5, and the middle hole 8 of the blowing nozzle 7 is connected to the The lamp holder socket 11 in the conical revolving seat 1 below penetrates through. The annular tension spring 6 is clamped in the slots 9 of several sliding claws 4, form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com