Preparation method ofprobiotic microcapsules by extruding granulation method and product prepared by method

A technology of extrusion granulation and microencapsulation, applied in the direction of bacteria, lactobacilli, bifidobacteria, etc. used in food preparation, can solve the problems of limited application fields, harsh application conditions, and less retention of probiotics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

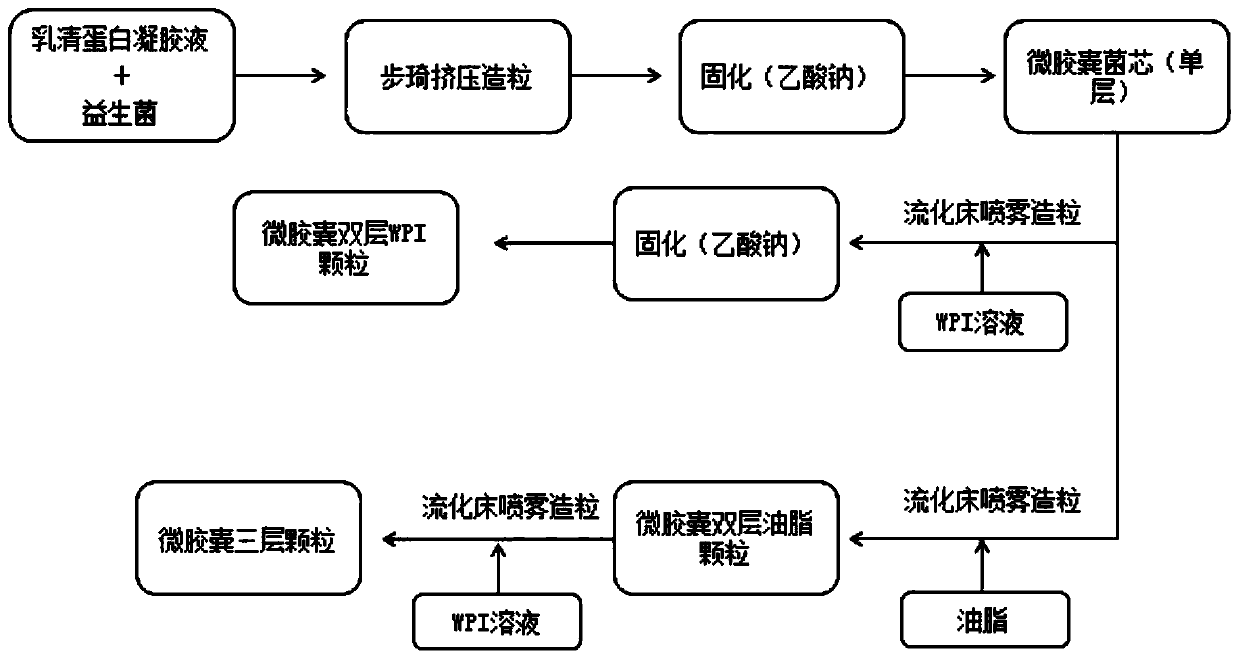

Method used

Image

Examples

Embodiment 1

[0193] 1. Raw materials (based on 1000g dry microcapsules)

[0194] WPI 750g (concentration 11%);

[0195] Water 6068g;

[0196] Bacillus coagulans powder 250g;

[0197] The curing agent solution is 6818ml, the concentration is 0.5mol / L, wherein: the curing agent is a mixed solution of sodium acetate, glacial acetic acid and Tween-20. Sodium acetate is 137g, glacial acetic acid is 100ml, Tween-20 is 2.9g, water is 6718g.

[0198] 2. Preparation method

[0199] a. Mix whey protein with water and stir at 180rpm / min at 4°C for 16 hours;

[0200] b. heat-treat the whey protein solution at 78°C, 95rpm / min, and 45 minutes;

[0201] c. Cool immediately at 0°C; store at 4°C for 12 hours;

[0202] d. Mix 137g of sodium acetate, 100ml of glacial acetic acid and 6718g of water to make a curing agent solution, adjust the pH to 4.6, add 2.9g of Tween-20, mix well and set aside.

[0203] e. Acute angle extrusion granulation method: nozzle combination 200μm / 400μm, voltage 1600mv, freq...

Embodiment 2

[0223] 1. Raw materials (based on 1000g dry microcapsules)

[0224] WPI (the first layer of wall material) 450g (concentration 11%);

[0225] WPI (second layer wall material) 300g (concentration 11%);

[0226] 6068g of water, including 3641g of water for the first layer of wall material and 2427g of water for the second layer of wall material;

[0227] Bacillus coagulans powder 250g;

[0228] The curing agent solution is 6818ml, the concentration is 0.5mol / L, wherein the curing agent is a mixed solution of sodium acetate, glacial acetic acid and Tween-20. Sodium acetate 137g, glacial acetic acid 100ml, Tween-20 2.9g, water 6718g.

[0229] 2. Preparation method

[0230] a. Mix whey protein with water and stir at 180rpm / min at 4°C for 16 hours;

[0231] b. heat-treat the whey protein solution at 78°C, 95rpm / min, and 45 minutes;

[0232] c. Cool immediately at 0°C; store at 4°C for 12 hours;

[0233] d. Mix 137g of sodium acetate, 100ml of glacial acetic acid and 6718g of ...

Embodiment 3

[0257] 1. Raw materials (based on 1000g dry microcapsules)

[0258] WPI (the first layer of wall material) 300g (concentration 11%);

[0259] Palm oil (second layer of wall material) 200g (concentration 100%);

[0260] WPI (the third wall material) 250g (concentration 11%);

[0261] 4450g of water, including 2427g of water for the first layer of wall material and 2023g of water for the third layer of wall material;

[0262] Bacillus coagulans powder 250g;

[0263] 5000ml of curing agent solution, concentration 0.5mol / L, wherein the curing agent is a mixed solution of sodium acetate, glacial acetic acid and Tween-20. Sodium acetate 101g, glacial acetic acid 74ml, Tween-20 2g, water 4926g.

[0264] 2. Preparation method

[0265] a. Mix whey protein with water and stir at 180rpm / min at 4°C for 16 hours;

[0266] b. heat-treat the whey protein solution at 78°C, 95rpm / min, and 45 minutes;

[0267] c. Cool immediately at 0°C; store at 4°C for 12 hours;

[0268] d. Mix 101g o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com