Soft package battery cell automatic disassembling equipment

A cell and automatic technology, which is applied in the field of automatic dismantling equipment for soft-packed cells, can solve problems such as health hazards, low efficiency of manual disassembly, and strong odor, and achieve the goals of improving accuracy, high degree of automation, and reducing risks Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

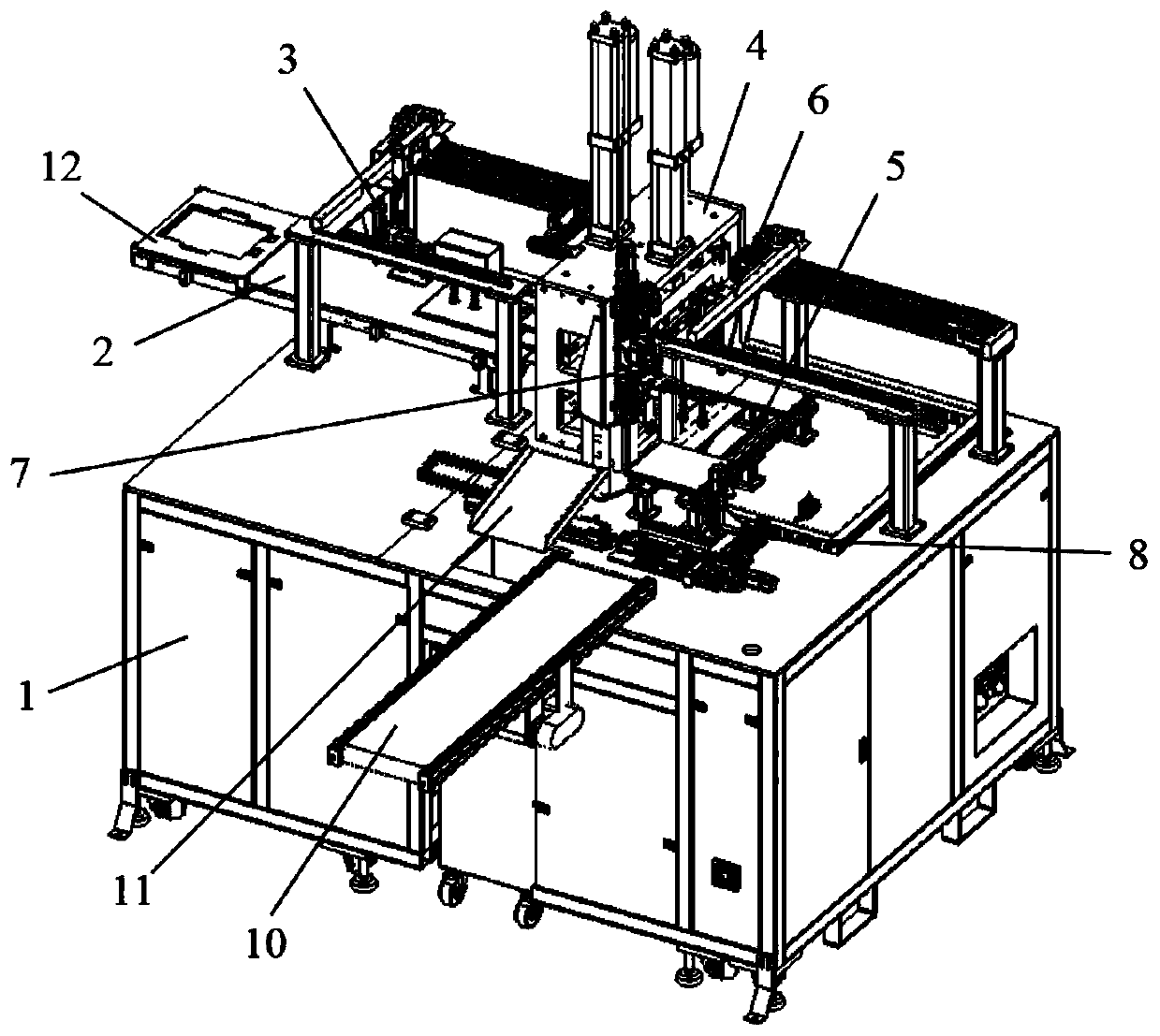

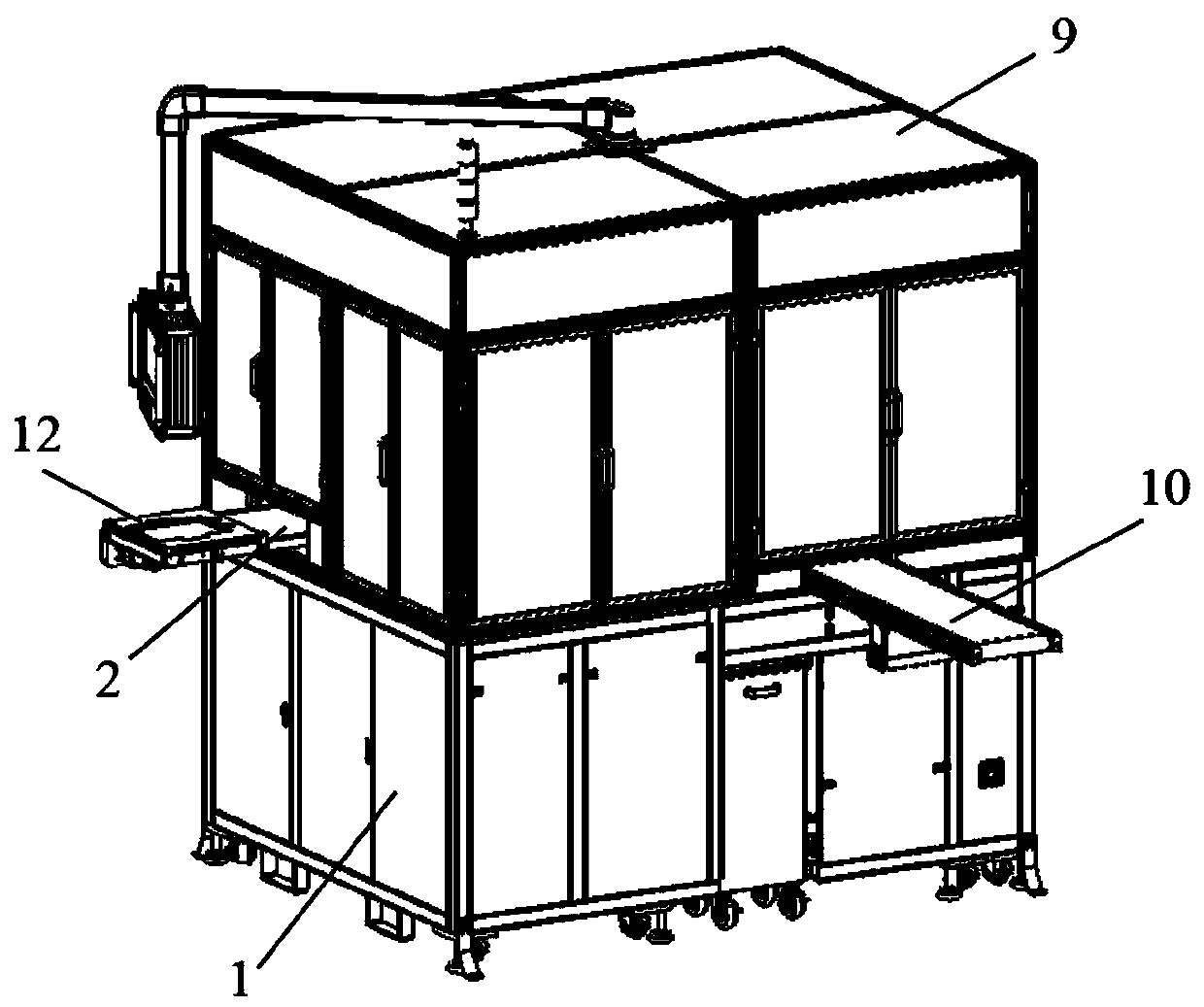

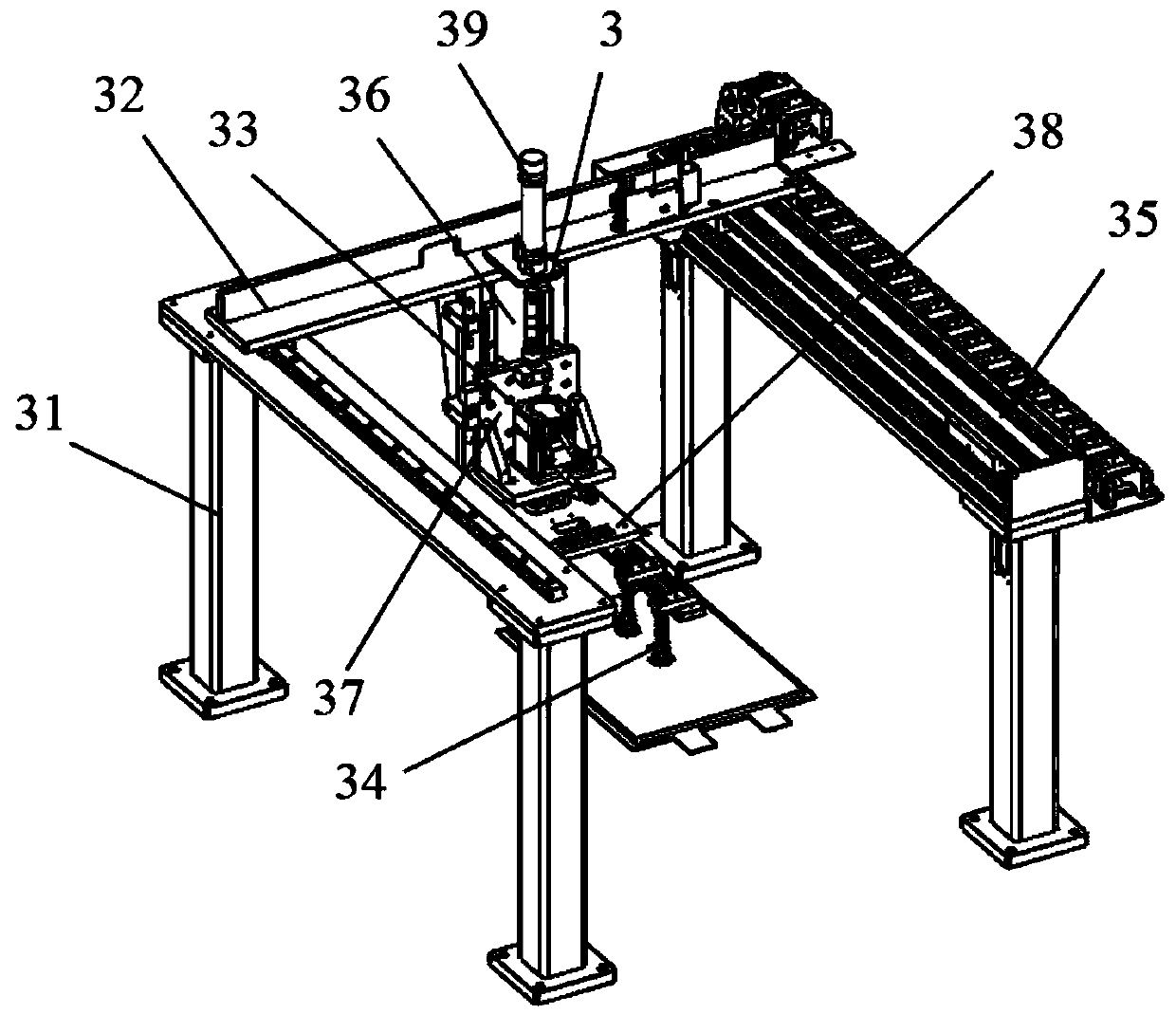

[0035] Please refer to figure 1, the present invention provides an automatic dismantling device for soft-packed batteries, including a workbench 1, on which a feeding conveying line 2, a transplanting and feeding manipulator 3, a shearing module 4, and an incoming material conveying line 5 are arranged. , transplanting and retrieving manipulator 6, automatic cutting outer packaging workstation and discharging line 10. The transplanting and feeding manipulator 3 is arranged at one end of the shearing module 4 close to the feeding conveying line 2 , and the transplanting and retrieving manipulator 6 is arranged at one end of the shearing module 4 near the incoming material conveying line 5 .

[0036] The feeding conveying line 2 and the incoming conveying line 5 are two mutually perpendicular conveying lines, and both the feeding conveying line 2 and the incoming conveying line 5 are provided with positioning fixtures 12 for placing pouch batteries. The positioning fixture 12 r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com