Fruit and vegetable core removing and slicing machine

A slicing machine, fruit and vegetable technology, used in fruit de-pitting devices, metal processing, food processing and other directions, can solve the problems of knife cutting fingers, affecting production efficiency, and fruit stone residues, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

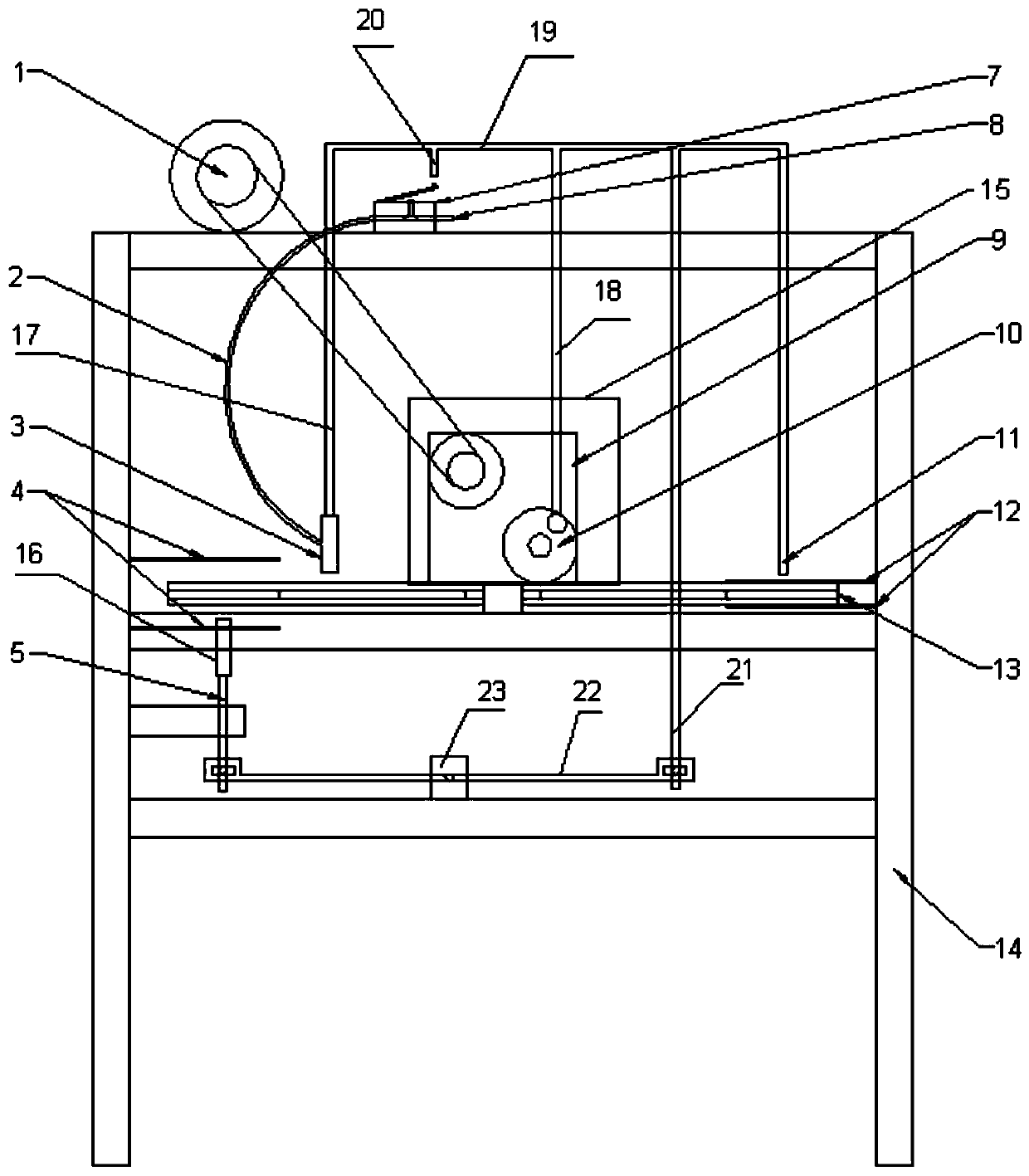

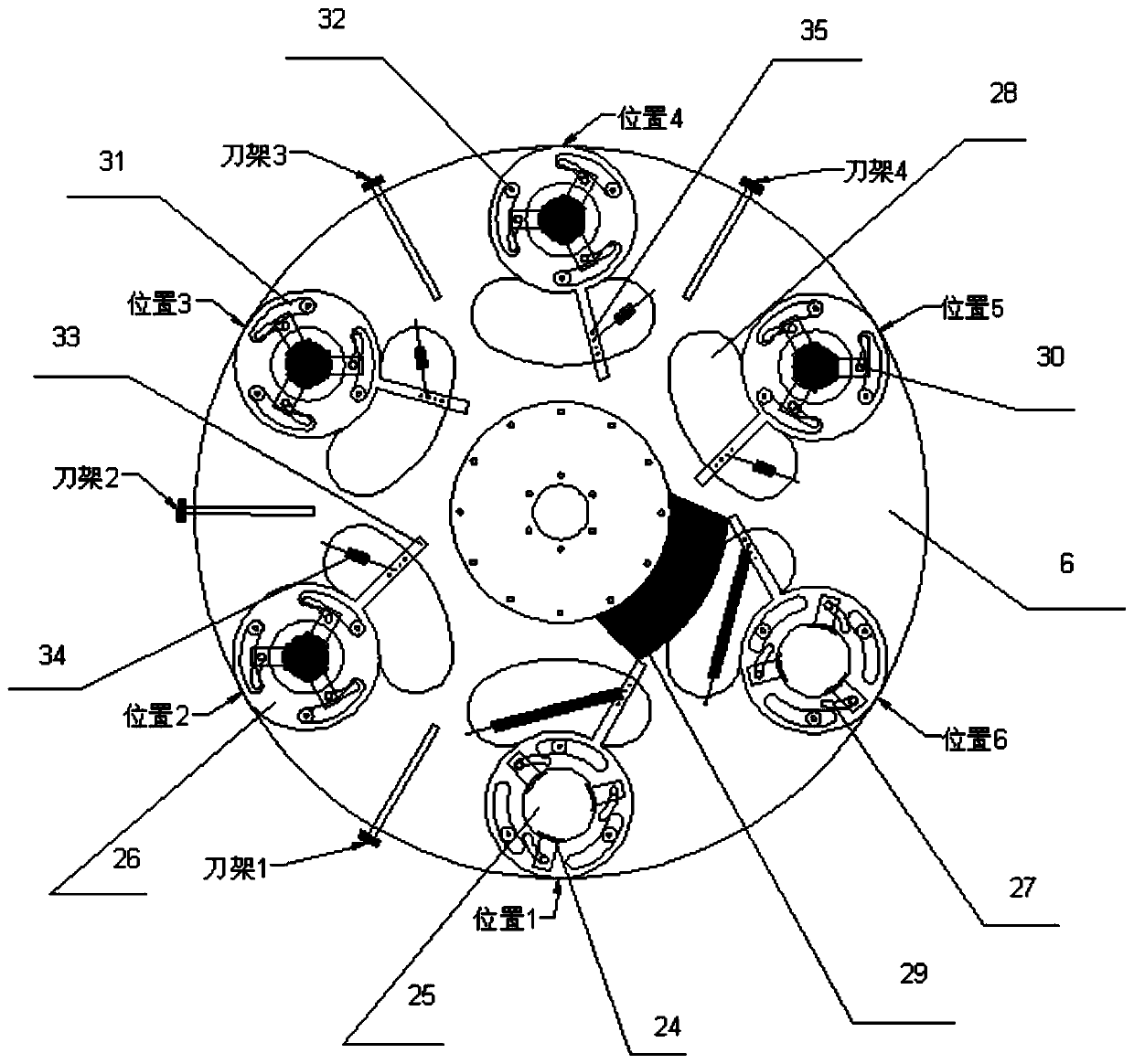

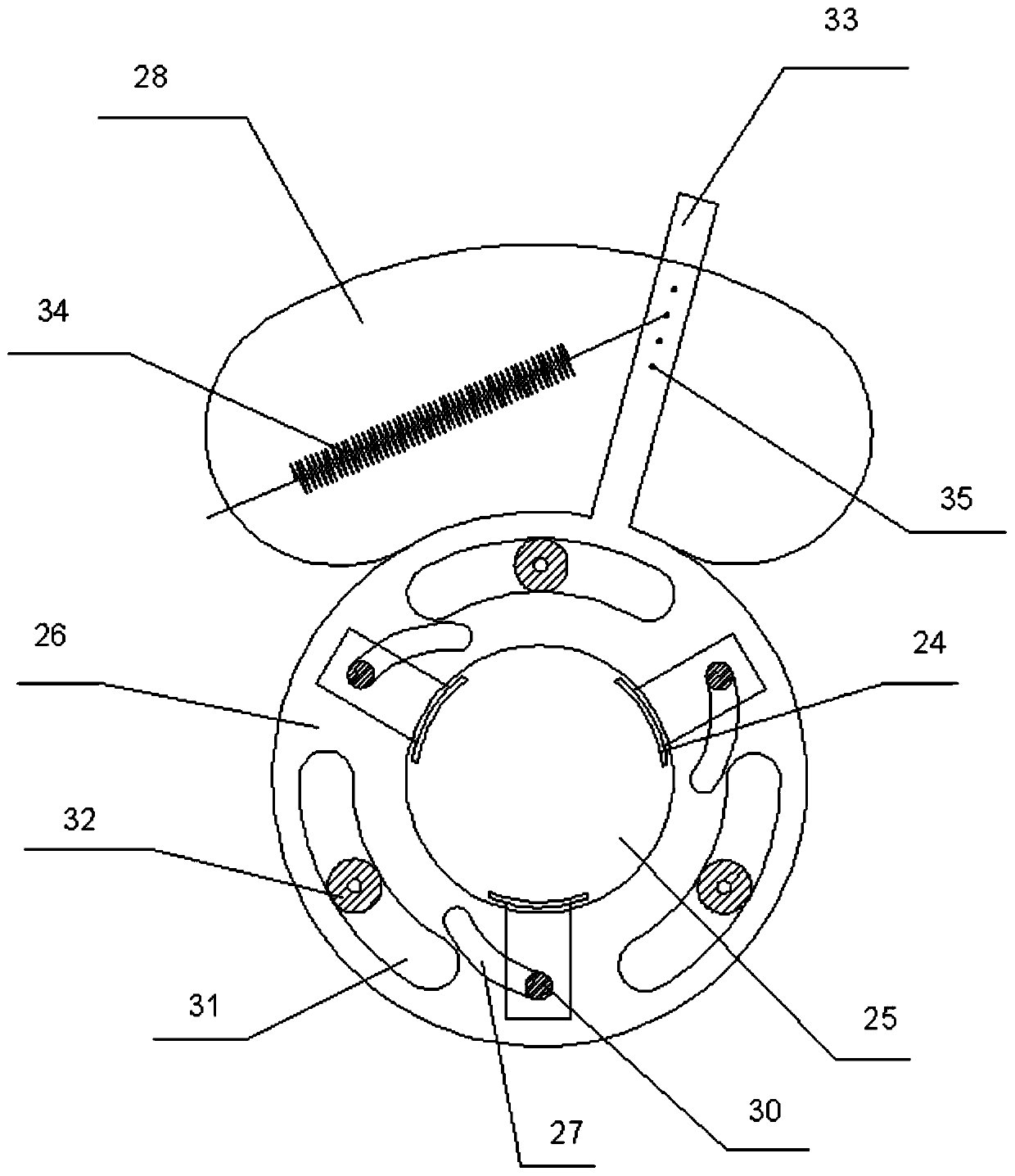

[0018] A fruit and vegetable pitting slicer, which includes a frame 14, an intermittent divider 15, a disc clamping device 13, a plurality of groups of different heights of knives installed in different directions around the disc clamping device, and mounted on the disc clamp The pre-opening push rod 5 below the holding device, the coring push rod 17 and the fruit removing push rod 11 installed above the disc clamping device, the disc clamping device is installed on the frame in rotation and separated by intermittent The intermittent separator is driven to rotate intermittently. A runner 10 is installed on the intermittent separator, and a driving jack 18 is installed eccentrically on the runner. The top of the driving jack is fixedly connected with the connecting rod 19, and the two ends of the connecting rod are connected with the connecting rod 19. The pitting ejector rod and the fruit removing ejector rod are connected, the middle part of the connecting rod is connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com