Slurry sintering device for producing soft magnetic ferrite particles

A soft ferrite and sintering device technology, applied in the manufacturing of magnetic materials, magnetic objects, inductors/transformers/magnets, etc., can solve the problems of low efficiency, bloated equipment, and can not meet the needs of use, and achieve accurate cutting and mixing. material, the sintering effect is better, and the effect that meets the needs of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

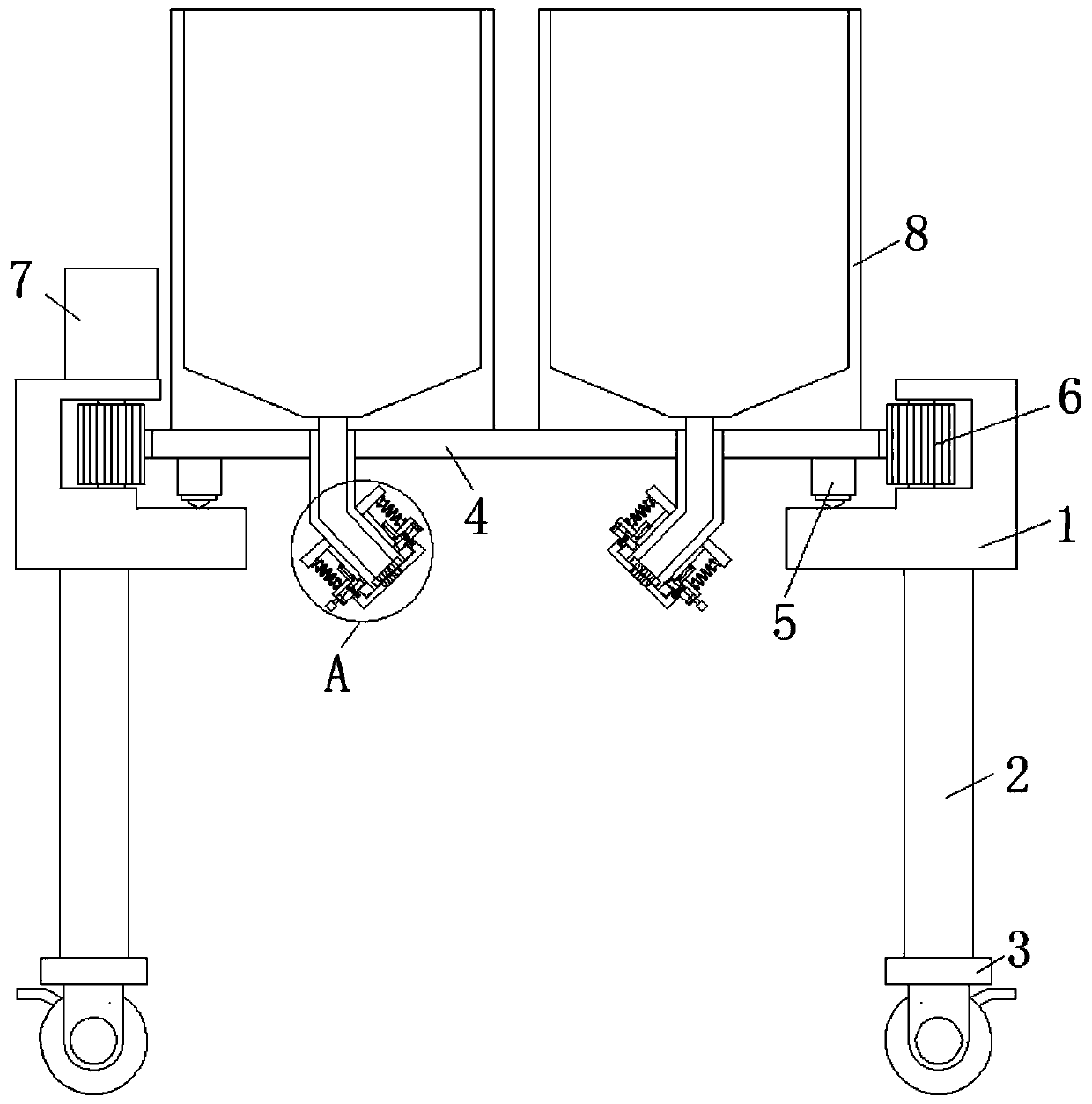

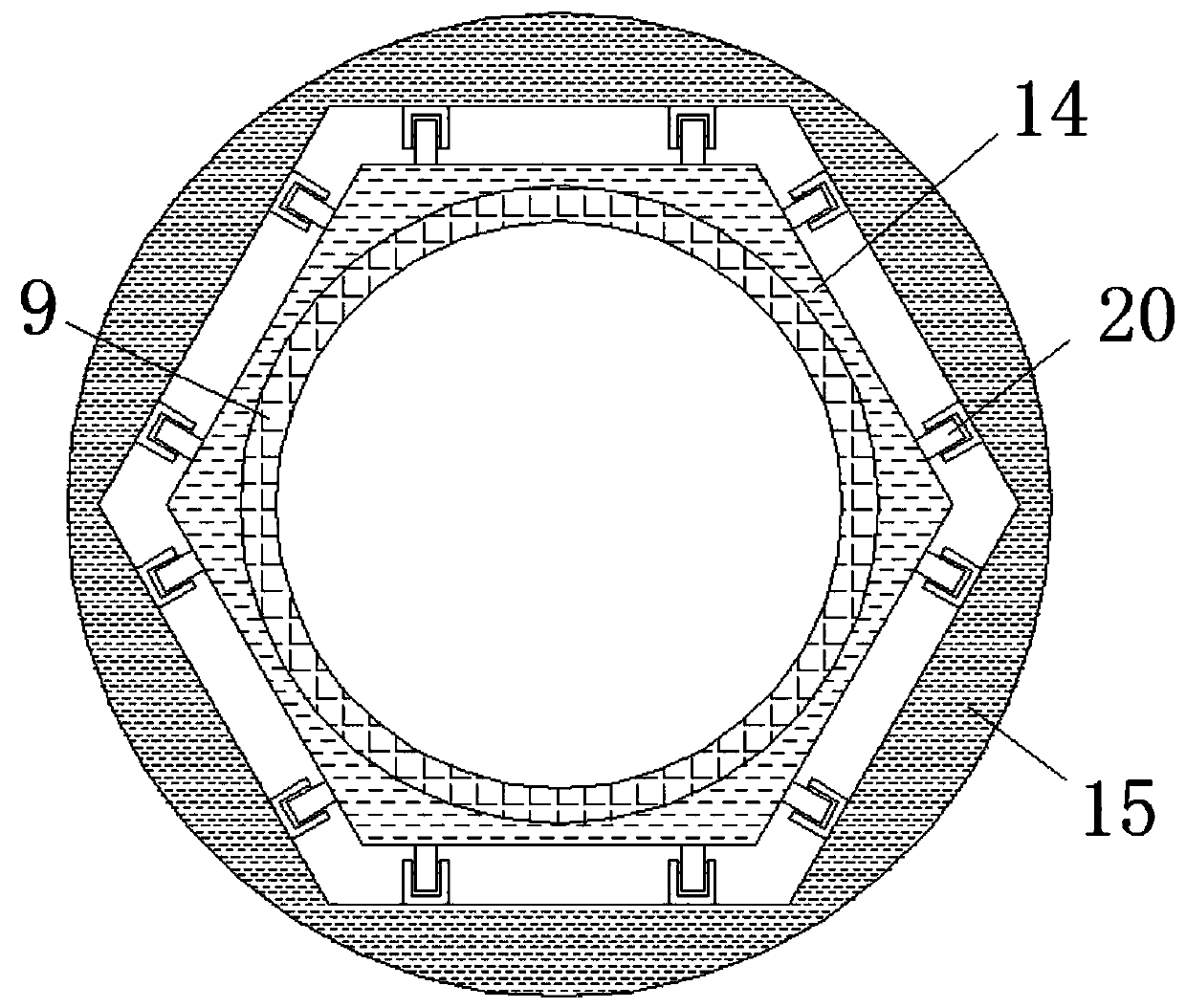

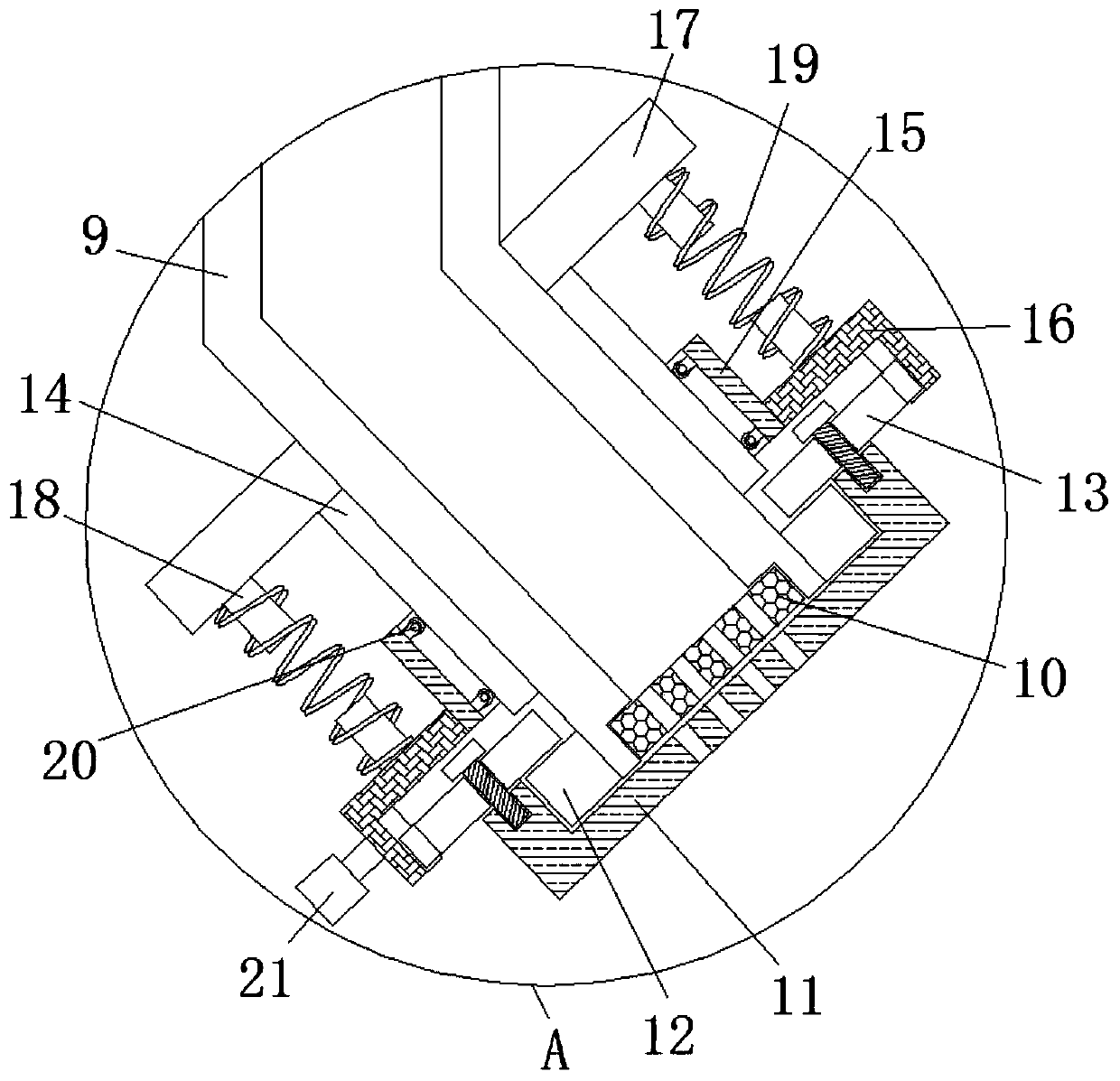

[0021] refer to Figure 1-3 A slurry sintering device for producing soft ferrite particles, comprising a mounting plate 1, the plate body of the mounting plate 1 is provided with a circular vertical through hole, and the top edge of the circular vertical through hole is provided with a ring groove, the bottom side of the mounting plate 1 is fixedly connected with several support columns 2, the inner side of the mounting plate 1 is provided with a support plate 4, and the bottom edge of the support plate 4 is provided with several equidistant ball universal balls 5, The bottom side of the universal ball 5 is in rolling contact with the inner wall of the bottom side of the ring groove. The vertical inner wall of the ring groove is provided with several side grooves, and the side grooves are rotated and connected with the limited rolling gear cylinder 6. The vertical one of the support plate 4 There is an external tooth groove on the side, and one side of the limiting rolling gea...

Embodiment 2

[0024] refer to Figure 1-3 , in this embodiment, it is basically the same as Embodiment 1, and more optimally, rollers 20 are provided on the inner walls of both ends of the sliding cylinder 15, and one side of the rollers 20 is connected in rolling contact with the inner wall of the polygonal track cylinder 14, and the ring gear cover One side of 16 is fixedly connected with handle 21, and the setting of handle 21 and roller 20 makes the movement of ring gear cover 16 smoother and labor-saving, and facilitates people's adjustment to the material passing hole. The inner side of sliding cylinder 15 is a polygonal structure, sliding The outer circular structure of the cylinder 15, the cooperation of the polygonal structure of the polygonal track cylinder 14 and the ring gear cover 16, and the elastic force of the return spring 19 make the engagement between the gear ring 13 and the ring gear cover 16 more stable, and play a role of insurance. As a result, the bottom ends of eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com