Directional adjustment and control method for oil reservoir endogenous functional microbes

A technology of functional microorganisms and microorganisms, which is applied in the direction of chemical instruments and methods, earth drilling, drilling compositions, etc., can solve the problems of poor pertinence of functional microorganisms and inability to activate functional microorganisms in a targeted and efficient manner, and achieve reduced dosage and field tests Good effect and improved activation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

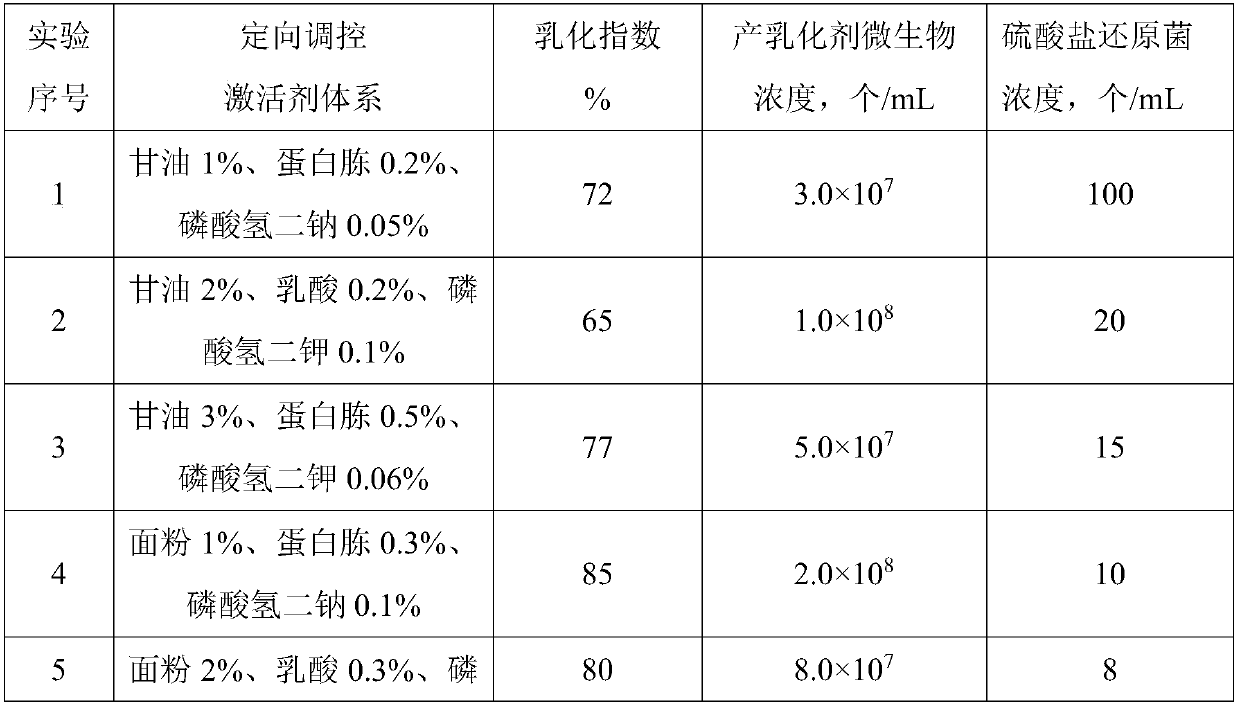

Examples

Embodiment 1

[0038] Test block G of an oil production plant in Shengli Oilfield 12 Overview: Reservoir temperature is 70°C, reservoir pressure is 12.3MPa, reservoir thickness is 6.5m, permeability is 800×10 -3 μm 2 , porosity 28%, crude oil viscosity 600mPa·s, comprehensive water cut 96.5%, recovery degree 15.8%, formation water salinity 11500mg / L, pore volume 2.0×10 5 m 3 , geological reserves 7.2×10 4 t. Utilize the method of the present invention to carry out microbial flooding to enhance oil recovery in this block, and concrete steps are as follows:

[0039] (1) Screening of test reservoirs

[0040] After sampling, testing and analysis, the test block G 12 There are emulsifier-producing microorganisms Brevibacterium and sulfate-reducing bacteria Desulfovibrio in formation water. Meet the screening criteria of the reservoir of the present invention.

[0041] (2) Phage isolation and amplification of sulfate-reducing bacteria

[0042] Sulfate-reducing bacteria phage isolation: ta...

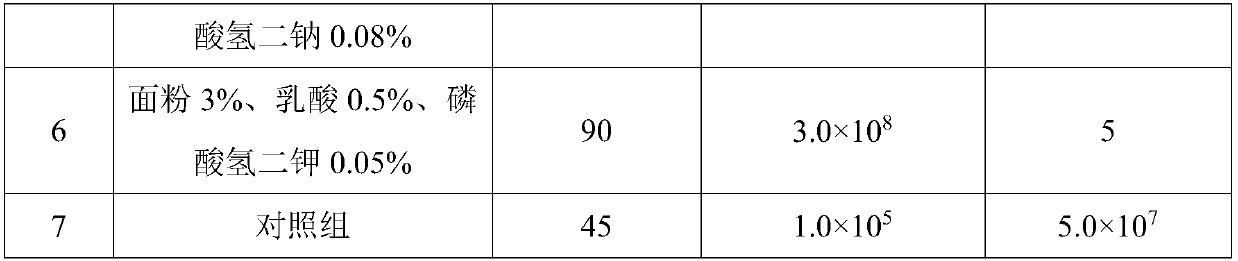

Embodiment 2

[0064] Test block G of an oil production plant in Shengli Oilfield 18 Overview: Reservoir temperature is 72°C, reservoir pressure is 10.3MPa, reservoir thickness is 10.8m, permeability is 1200×10 -3 μm 2 , porosity 32.5%, crude oil viscosity 1523mPa·s, comprehensive water cut 97.2%, recovery degree 15.2%, formation water salinity 25682mg / L, pore volume 5.0×10 5 m 3 , geological reserves 1.2×10 5 t. Utilize the method of the present invention to carry out microbial flooding to enhance oil recovery in this block, and concrete steps are as follows:

[0065] (1) Screening of test reservoirs

[0066] After sampling, testing and analysis, the test block G 18 Biosurfactant-producing microorganisms Bacillus and sulfate-reducing bacteria Desulfococcus are present in formation water. Meet the screening criteria of the reservoir of the present invention.

[0067] (2) Phage isolation and amplification of sulfate-reducing bacteria

[0068] Sulfate-reducing bacteria phage isolation...

Embodiment 3

[0090] Test block F of an oil production plant in Shengli Oilfield 21 Overview: Reservoir temperature is 85°C, reservoir pressure is 13.2MPa, reservoir thickness is 15.2m, permeability is 1000×10 -3 μm 2 , porosity 31.2%, crude oil viscosity 1152mPa·s, comprehensive water cut 97.8%, recovery degree 23.5%, formation water salinity 22785mg / L, pore volume 8.0×10 5 m 3 , geological reserves 2.1×10 5 t. Utilize the method of the present invention to carry out microbial flooding to enhance oil recovery in this block, and concrete steps are as follows:

[0091] (1) Screening of test reservoirs

[0092] After sampling, detection and analysis, the test block F 21 There are emulsifier-producing microorganisms Rhodococcus and sulfate-reducing bacteria Desulfobacter in formation water. Meet the screening criteria of the reservoir of the present invention.

[0093] (2) Phage isolation and amplification of sulfate-reducing bacteria

[0094] Sulfate-reducing bacteria phage isolation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com