Three-dimensional wallpaper and production method thereof

A production method and technology of wallpaper, applied in the direction of printing, printing process, coating, etc. for the production of special varieties of printed matter, can solve the problems that rarely meet the requirements of unique shapes, strong texture changes, insufficient consumer products, and embossed patterns. Can not match and other problems, to achieve the effect of easy control of design, unlimited pattern, beautiful texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

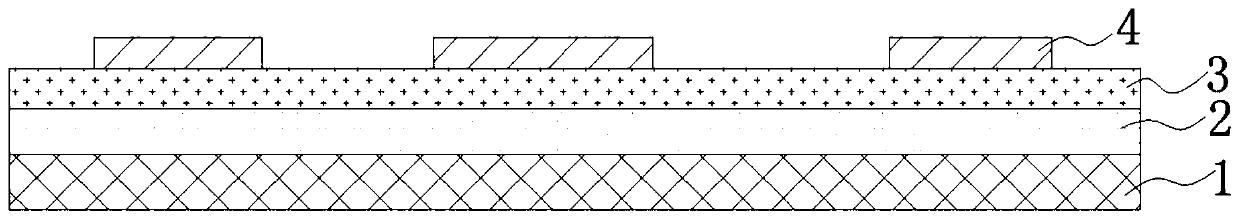

[0109] (1) Brush the precoating solution on the non-woven fabric with a thickness of 1mm, and dry it at 140°C to form a primer layer with a thickness of 0.03mm to 0.04mm;

[0110] (2) Using digital printing, printing foaming slurry on the primer layer, forming a foaming slurry layer after drying at 150°C; then using digital printing, partially printing on the foaming slurry layer to prevent foaming Foam slurry, dry at 170°C to form a foam-inhibiting slurry layer, then print ink on the raised surface of the foaming slurry layer and the foaming-inhibiting slurry layer to form an ink layer; finally foam at 190°C Foaming to obtain the three-dimensional wallpaper after foaming; the above-mentioned process of compounding each layer is preferably at 2.0×10 5 Operate under the pressure of Pa; Obtain three-dimensional wallpaper;

[0111] The thickness of the anti-foaming slurry layer of the three-dimensional wallpaper is 0.1 mm, the thickness of the concave surface part of the foaming...

Embodiment 2

[0115] Produce three-dimensional wallpaper according to the production method that embodiment 1 provides; Difference is:

[0116] The foaming slurry comprises the following components: 120 parts by weight of PVC resin, 1 part by weight of polydimethylsiloxane, 1.5 parts by weight of potassium zinc stabilizer, 7 parts by weight of azodicarbonamide, and 15 parts by weight of calcium carbonate , 30 parts by weight of titanium dioxide, 3 parts by weight of polyvinyl alcohol, 2 parts by weight of wormwood powder, 3 parts by weight of ammonium dihydrogen phosphate, 75 parts by weight of butyl acetate, and 2 parts by weight of CT catalyst.

[0117] The anti-foaming slurry comprises the following components: 7 parts by weight of benzotriazole, 0.25 parts by weight of anionic agent, 1.5 parts by weight of acrylic resin, 1.5 parts by weight of vinyl acetate resin, 2.5 parts by weight of polyethylene glycol and glycerin , 0.5 parts by weight of sodium hydroxide, and 16 parts by weight of...

Embodiment 3

[0119] Produce three-dimensional wallpaper according to the production method that embodiment 1 provides; Difference is:

[0120] The foaming slurry comprises the following components: 120 parts by weight of acrylate resin, 1 part by weight of polydimethylsiloxane, 1.5 parts by weight of potassium zinc stabilizer, 7 parts by weight of diphenylsulfonyl hydrazide p-oxide, calcium carbonate 15 parts by weight, 30 parts by weight of titanium dioxide, 3 parts by weight of polyvinyl alcohol, 2 parts by weight of wormwood powder, 5 parts by weight of ammonium dihydrogen phosphate, 75 parts by weight of butyl acetate, and 5 parts by weight of CT catalyst.

[0121] The anti-foaming slurry comprises the following components: 8 parts by weight of benzotriazole, 0.3 parts by weight of anionic agent, 1.5 parts by weight of acrylic resin, 1.5 parts by weight of vinyl acetate resin, 2.5 parts by weight of polysorbate, sodium hydroxide 0.5 parts by weight, 16 parts by weight of water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com