Sewing thread turn sewing method for sewing machine

A sewing machine and sewing thread technology, which is applied in the field of sewing thread turning, can solve the problems of wasting sewing thread, unsightly turning pattern, time-consuming and the like.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to have a more complete and clear disclosure of the technical content used in the present invention, the purpose of the invention and the effects achieved, the detailed description is given below, and please also refer to the disclosed drawings and figure numbers:

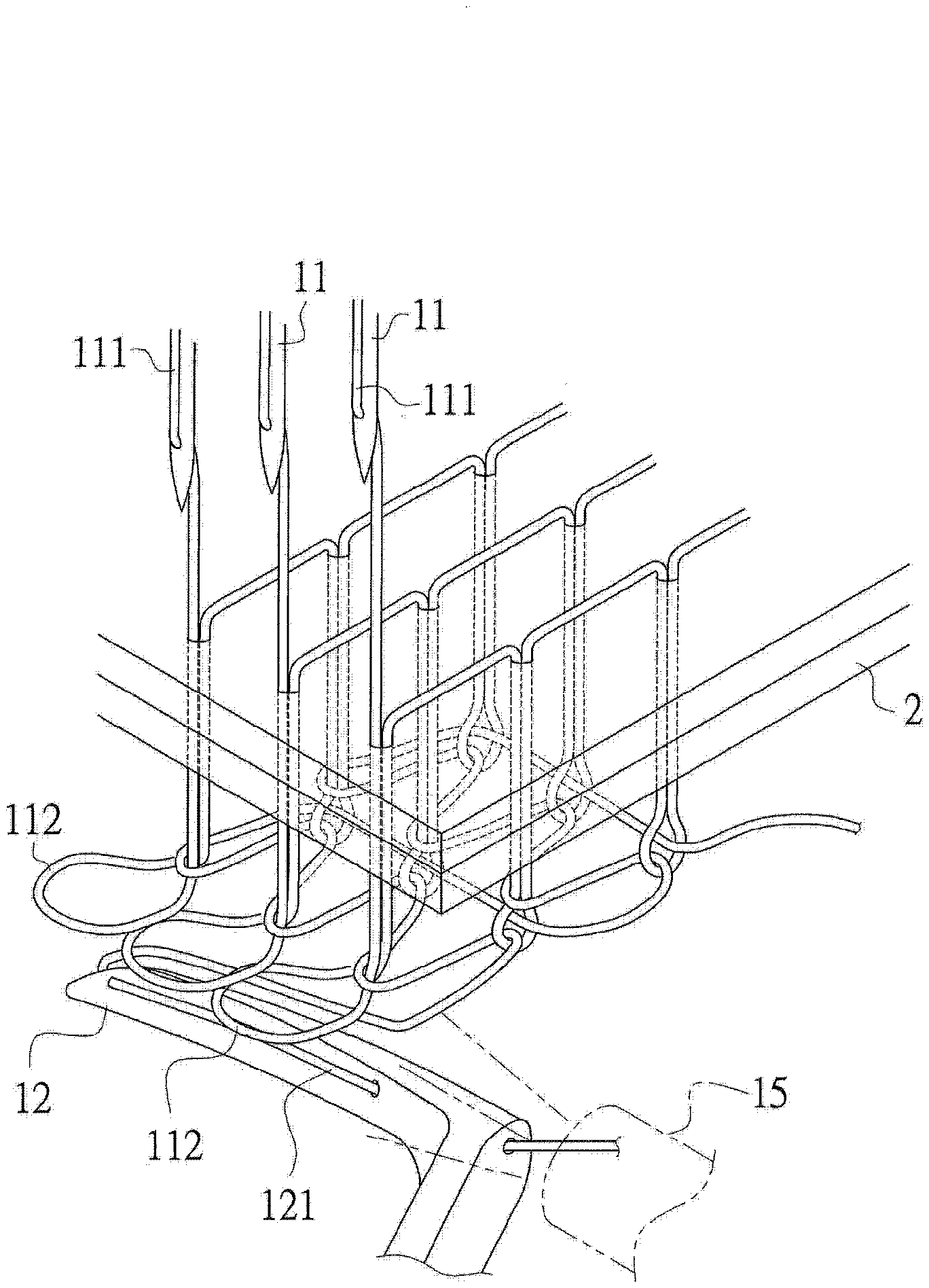

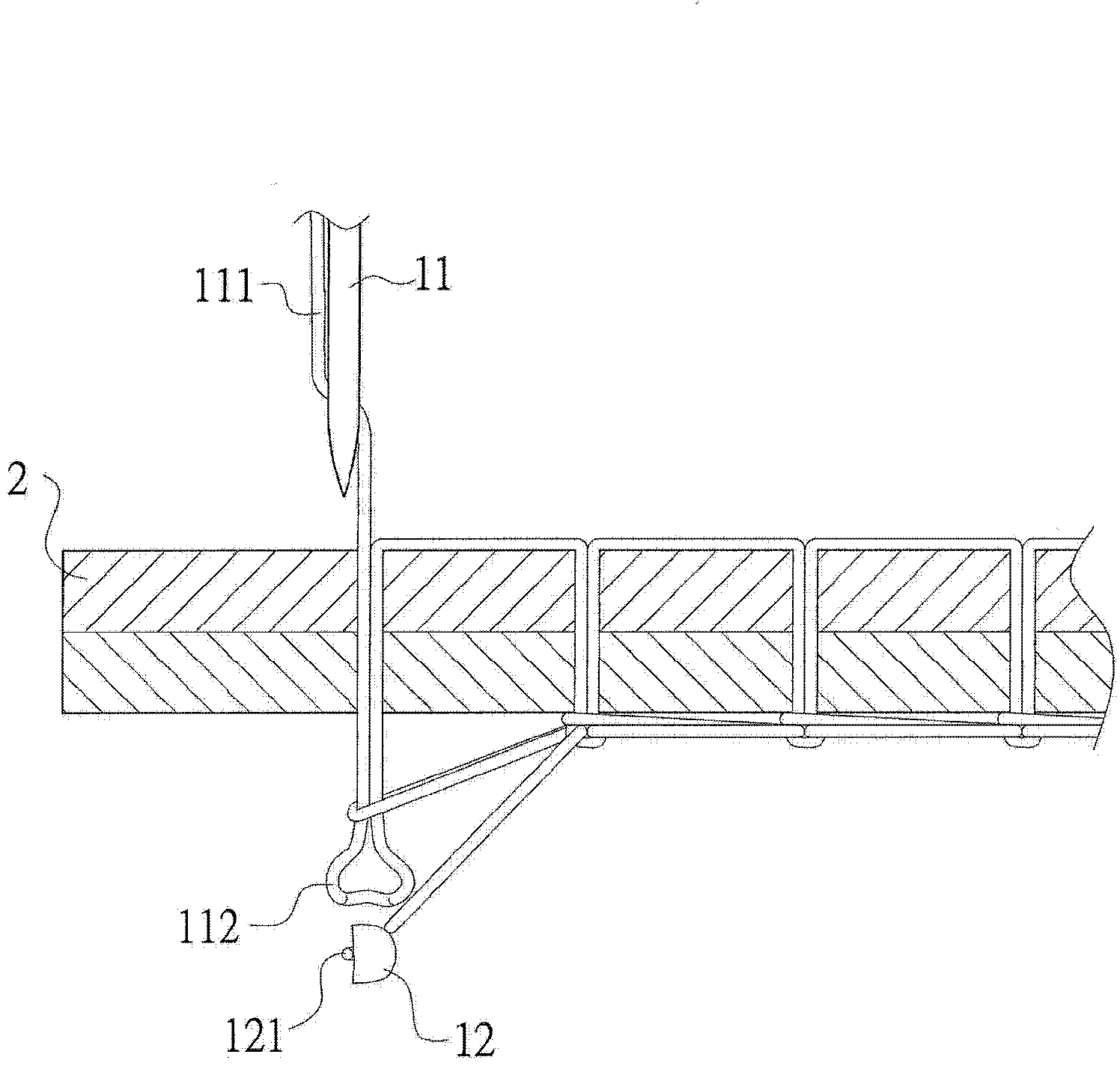

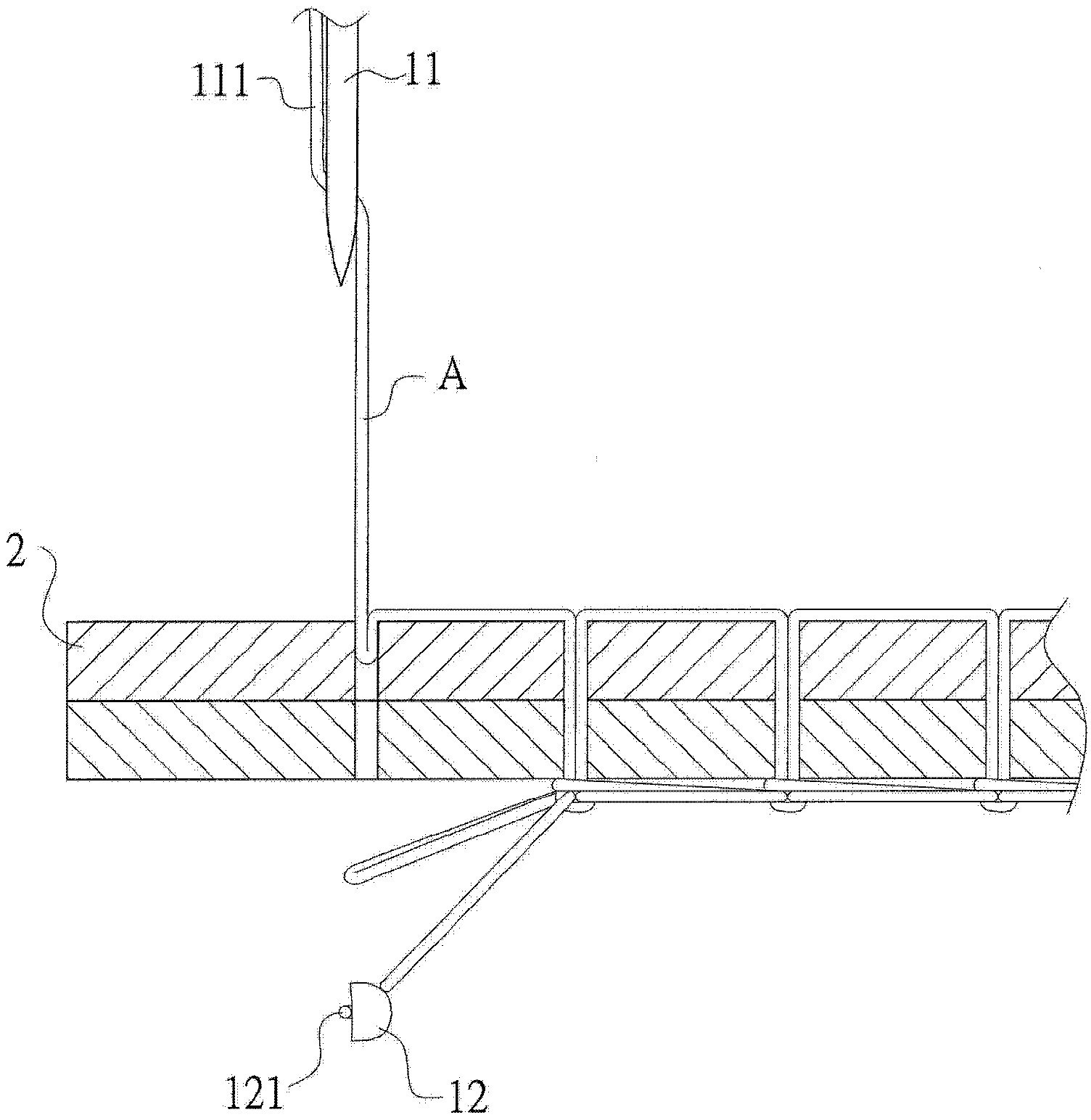

[0041] First, see figure 1 The schematic diagram of the three-dimensional structure of the present invention shown, the present invention is mainly provided with the upper needle 11 corresponding to the upper end of the needle plate, and the lower shuttle needle group 12 corresponding to the lower end of the needle plate (it can be different according to the sewing machine of different functions) difference, such as the number of needles in the lower shuttle of the three cars or the overlock sewing machine is different), and a coil pushing device 15 is provided at the lower end of the needle plate (not shown in the figure), and the coil pushing device 15 can be driven by an electric control device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com