System and method for measuring horizontal deformation of pipe jacking working well

A measurement system and measurement method technology, applied in basic structure engineering, basic structure testing, construction, etc., can solve problems such as damage to the bottom of the inclinometer pipe, unable to measure normally, and achieve the effect of ensuring construction safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the purpose, technical solution and advantages of the present invention clearer, the embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

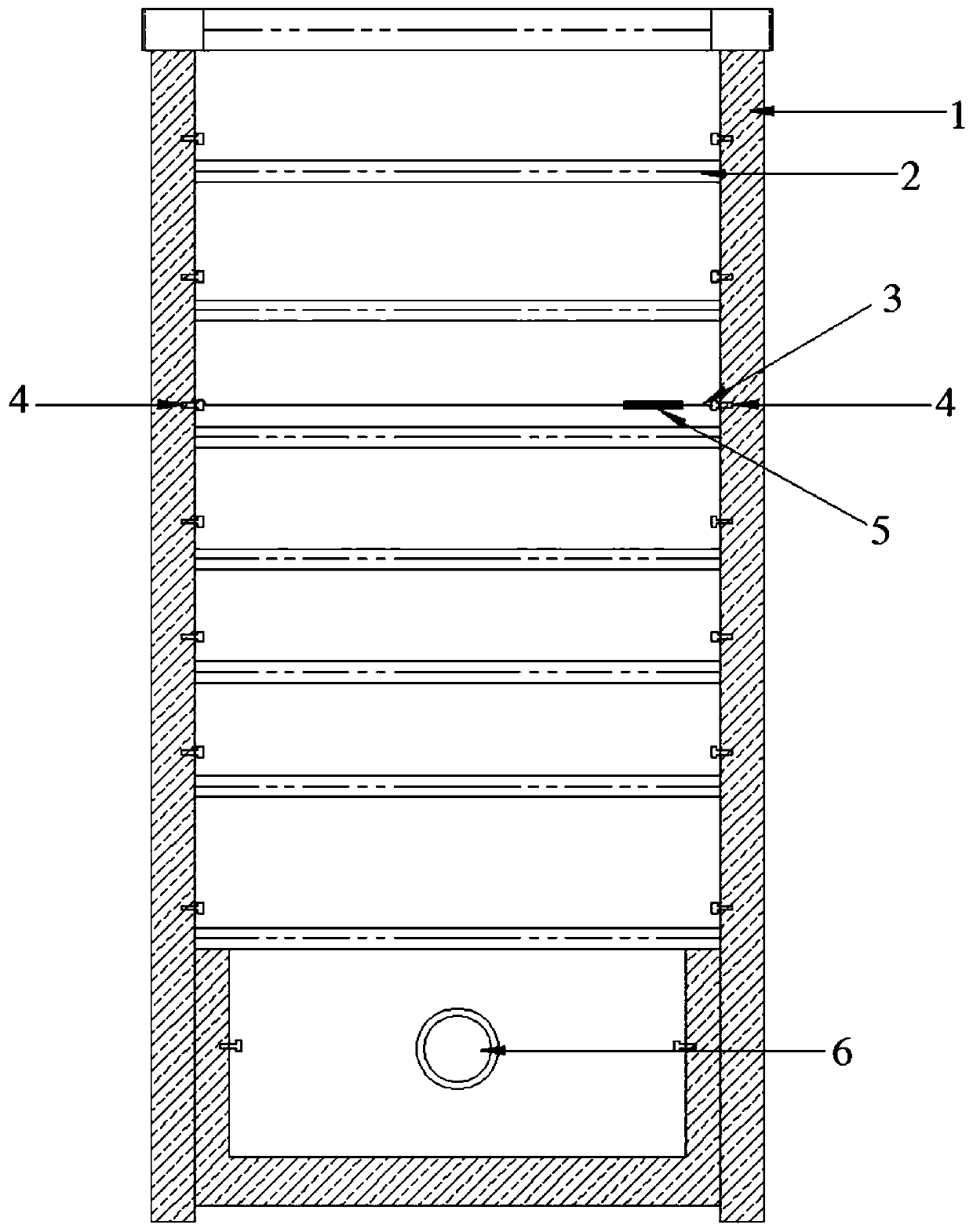

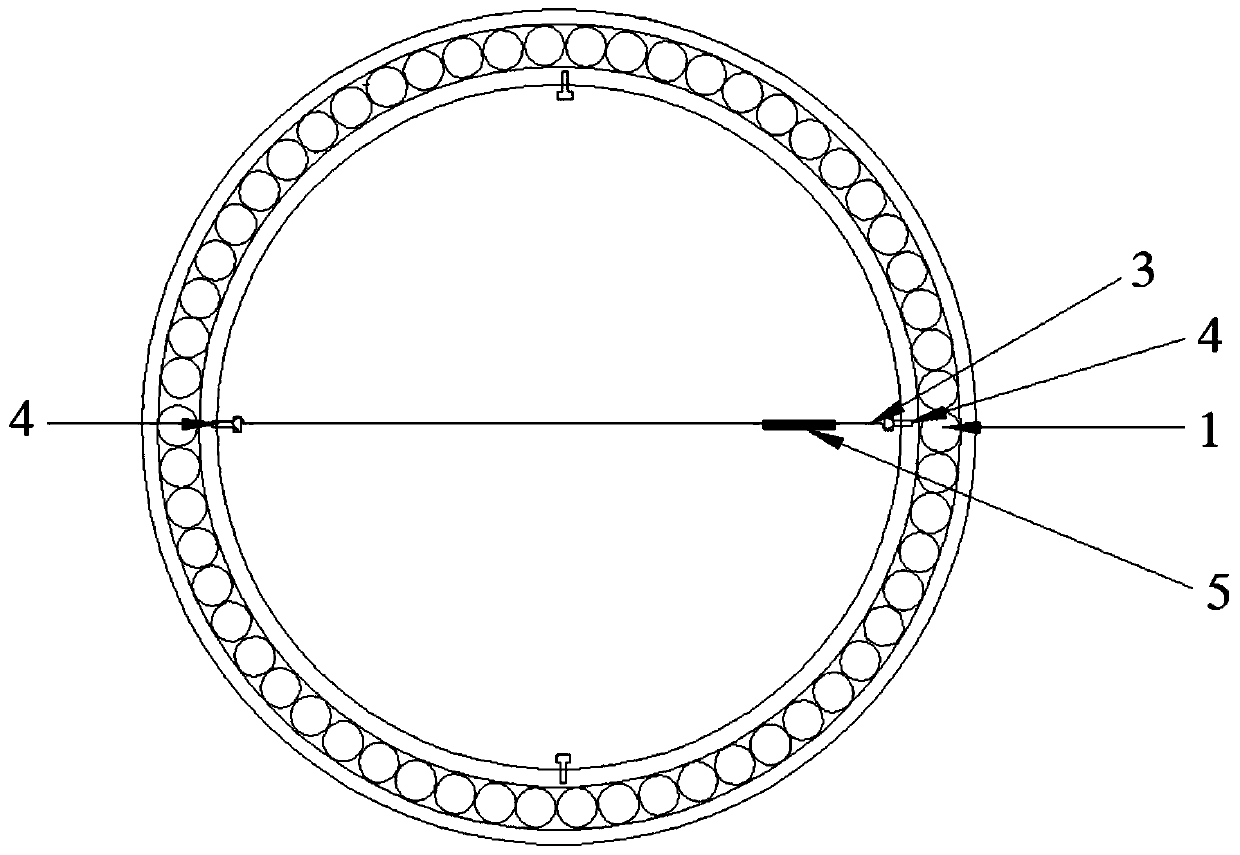

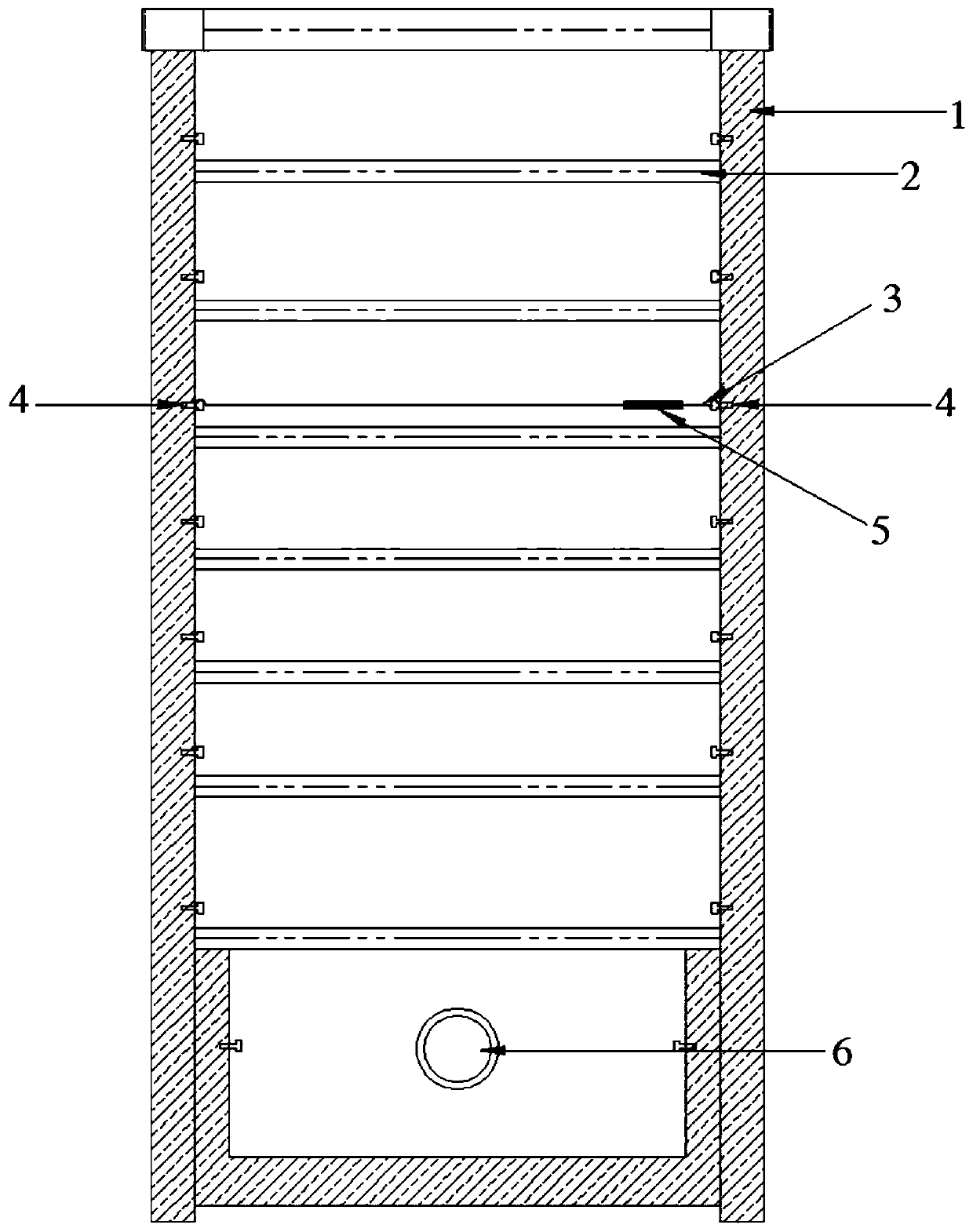

[0025] See figure 1 and figure 2 , the embodiment of the present invention provides a horizontal deformation measurement system for pipe jacking wells, including a convergent gauge 5 and multiple pairs of fixing parts 4 .

[0026] Every pair of said fixing parts 4 is fixed on the opposite side walls of the supporting structure 1 in the pipe jacking well, and the paired two said fixing parts 4 are located at the same height, and said fixing parts 4 have 5 of the hook 3 to match the matching part. The hook 3 of the convergent meter 5 cooperates with the matching portion so that the convergent meter 5 is detachably connected to the fixing member 4, and the two hooks 3 of the convergent meter 5 are connected to each pair of the fixing members. 4 connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com