Mountainous area high-pier bridge step dislocation construction method

A construction method and high pier technology, applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of high pier folded web bridges in mountainous areas, etc., and achieve convenient installation and lifting, overcome limitations, and process connection. reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

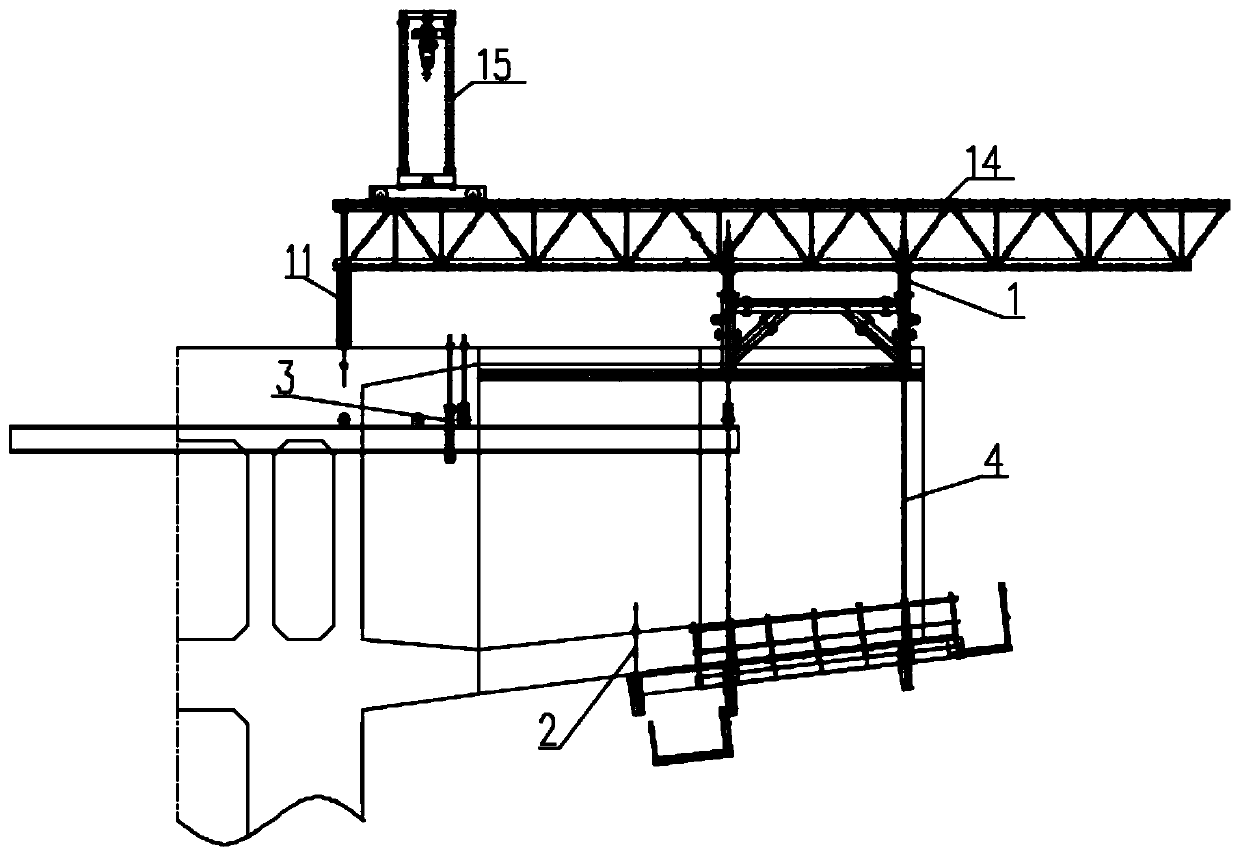

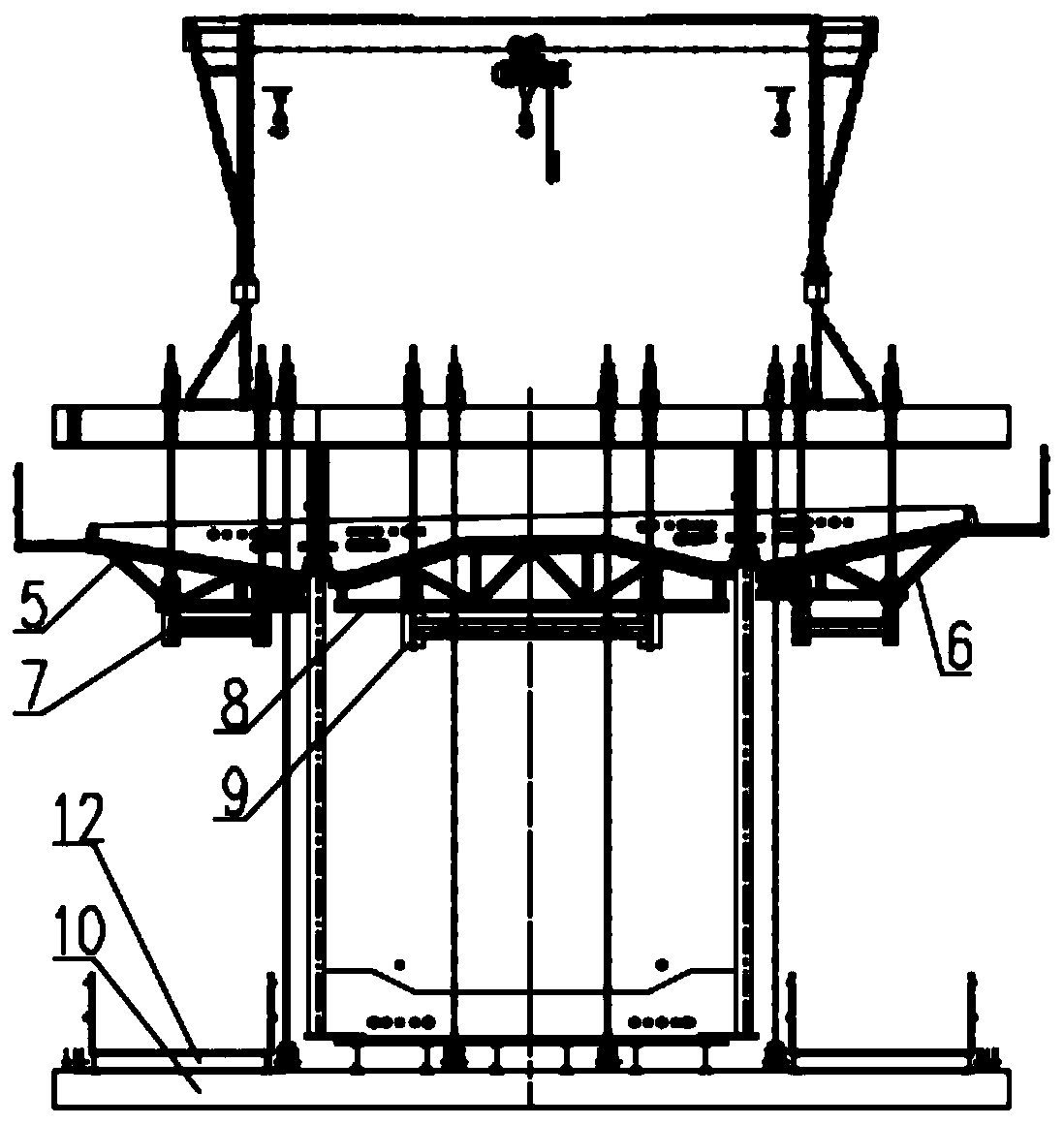

[0029] Such as Figure 1-Figure 3 As shown, the step dislocation construction method of the bridge with high pier in mountainous area in the present embodiment comprises the following steps:

[0030] Step 1: The hanging basket truss walks to the N section, and the template is installed to bind the bottom plate reinforcement of the N section and the roof reinforcement of the N-1 section;

[0031] Step 2: Concrete is poured for the N-segment bottom plate and the N-1 segment roof slab, and at the same time, the N+1 segment folded web is installed and constructed by self-hoisting the folded web with a hanging basket;

[0032] Step 3: The hanging basket truss travels to the N+1 segment, tensions the prestressed roof plate of the N-1 segment, and reciprocates in sequence for the cycle of the next segment.

[0033] The construction method in the present invention expands one operation area to three operation areas, and the three segments are constructed independently and synchronous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com