Cool multifunctional elastic fabric

A multi-functional and elastic technology, applied in the field of fabrics, can solve the problems of not meeting the daily use standard of cool fabrics and reducing the cooling performance, and achieve the effects of excellent elasticity, high industrial value and high development prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

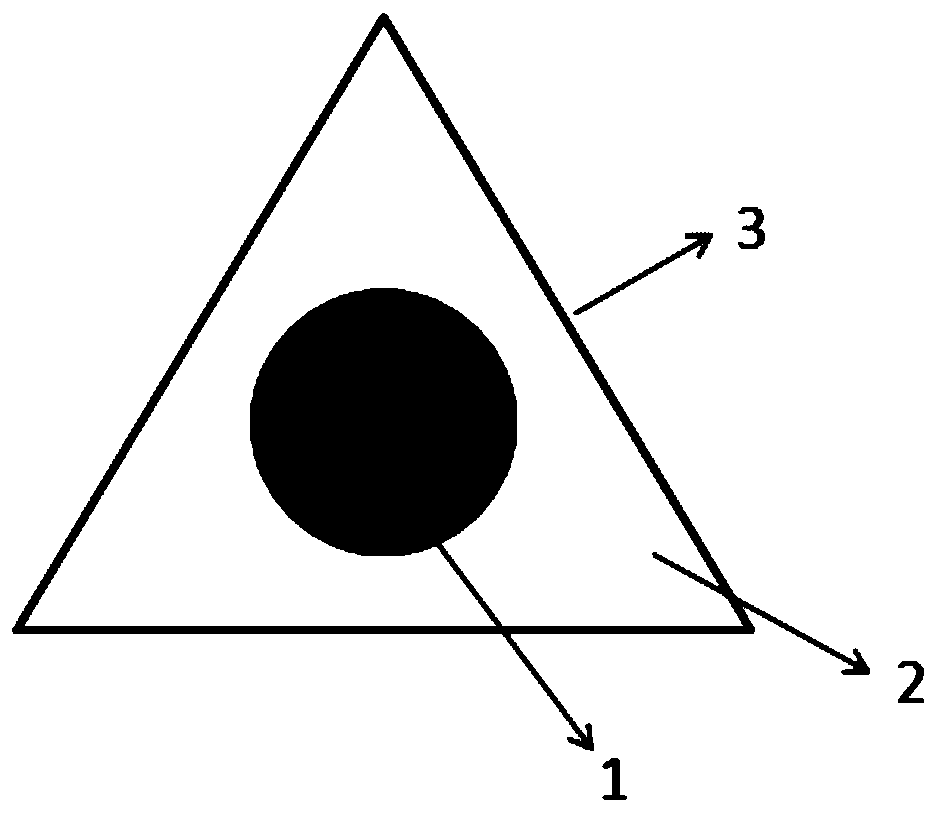

[0029] In order to solve the above-mentioned technical problems, the present invention provides a cool multifunctional elastic fabric, which is prepared from cool-feeling composite fiber filaments, and the preparation method of the cool-feeling composite fiber filaments comprises the following steps:

[0030] a. Preparation of inner layer fiber solution: weigh 3 to 5 parts of cooling substance A in parts by mass, add 77 to 85 parts of organic solvent and mix evenly, add 12 to 18 parts of cellulose acetate, stir and dissolve to obtain the inner layer fiber solution;

[0031] b. Preparation of outer layer fiber solution: in parts by mass, add 2 to 4 parts of cooling substance B, 1 to 2 parts of polyether polyol, 1 to 3 parts of organic acid, and 67 to 78 parts by mass under stirring conditions 80-90% cellulose solvent, after mixing evenly, add 10-14 parts of cotton fiber and 8-10 parts of thickener in sequence, and continue to stir until a uniform solution is obtained, that is, ...

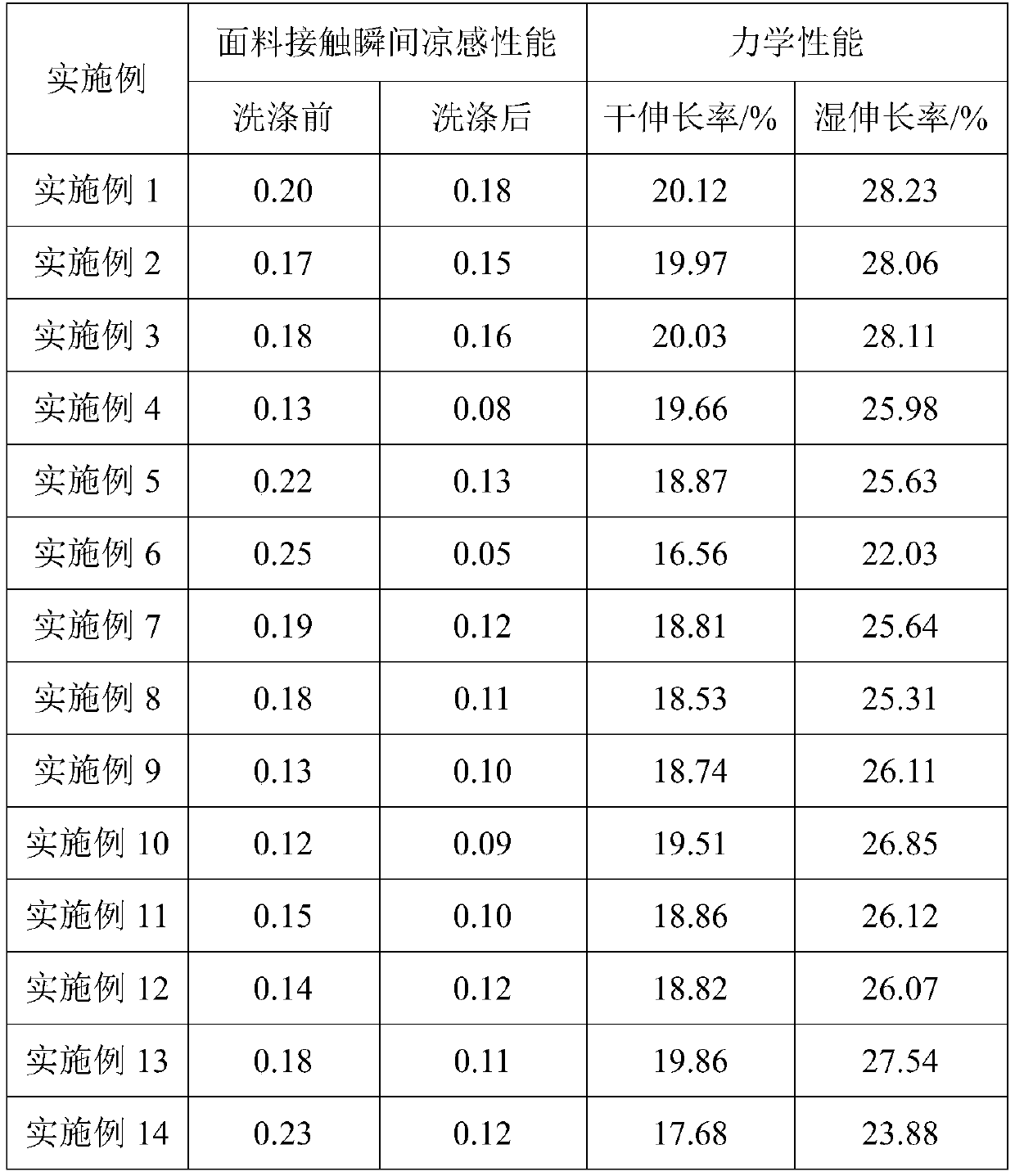

Embodiment 1

[0103] Embodiment 1 of the present invention provides a kind of cool multi-functional elastic fabric, and it is prepared from cool-feeling composite fiber silk, and the preparation method of described cool-feeling composite fiber silk comprises the following steps:

[0104] a. Preparation of the inner layer fiber solution: in parts by mass, weigh 4 parts of cooling sensation substance A, add 81 parts of organic solvent and mix evenly, add 15 parts of cellulose acetate, stir and dissolve to obtain the inner layer fiber solution;

[0105] b. Preparation of outer layer fiber solution: in parts by mass, add 3 parts of cooling substance B, 1 part of polyether polyol, 2 parts of organic acid, and 73 parts of cellulose solvent with a mass percentage of 86.7% under stirring conditions, After mixing evenly, add 12 parts of cotton fiber and 9 parts of thickener in turn, and continue to stir until a uniform solution is obtained, that is, the outer fiber solution;

[0106] c. Spinning: th...

Embodiment 2

[0126] Embodiment 2 of the present invention provides a kind of cool multifunctional elastic fabric, which is prepared from cool feeling composite fiber filaments, and the preparation method of the cool feeling composite fiber filaments comprises the following steps:

[0127] a. Preparation of the inner layer fiber solution: in parts by mass, weigh 3 parts of cooling sensation substance A, add 77 parts of organic solvent and mix evenly, add 12 parts of cellulose acetate, stir and dissolve to obtain the inner layer fiber solution;

[0128] b. Preparation of outer layer fiber solution: in parts by mass, add 2 parts of cooling substance B, 1 part of polyether polyol, 1 part of organic acid, and 67 parts of cellulose solvent with a mass percentage of 86.7% under stirring conditions, After mixing evenly, add 10 parts of cotton fiber and 8 parts of thickener in turn, and continue to stir until a uniform solution is obtained, that is, the outer fiber solution;

[0129] c. Spinning: t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com