PVDF@kuast-8 nanofiber composite film for triboelectric nanogenerator and preparation method thereof

A KUAST-8, nanogenerator technology, applied in the directions of triboelectric generator, fiber processing, fiber chemical characteristics, etc., can solve the problems of few reports on the application of triboelectric nanogenerator, and achieve easy industrialized production, simple preparation method, good practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

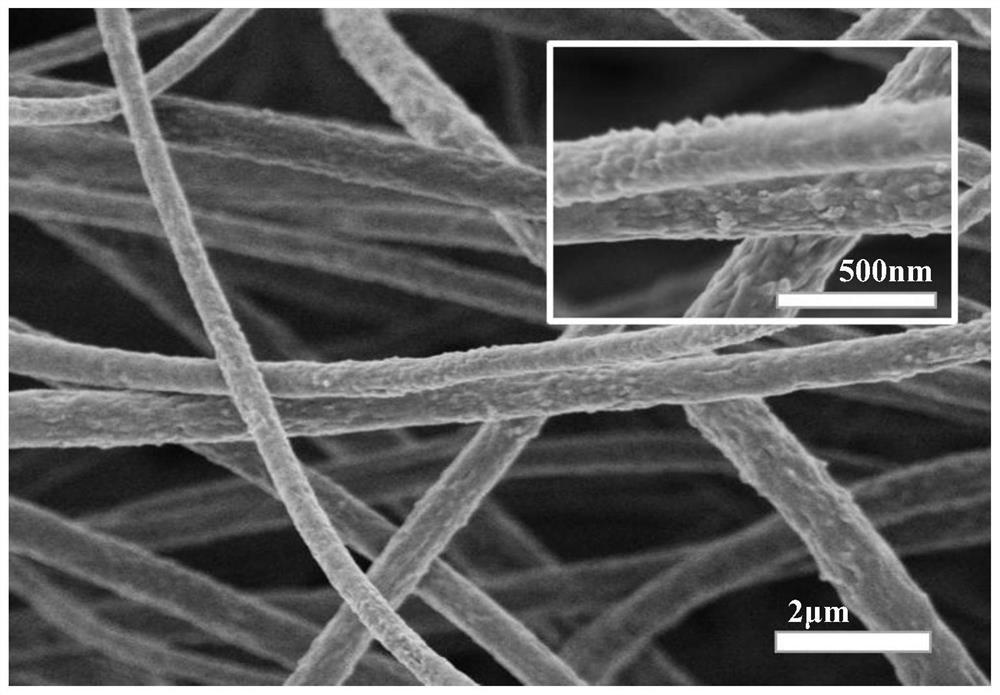

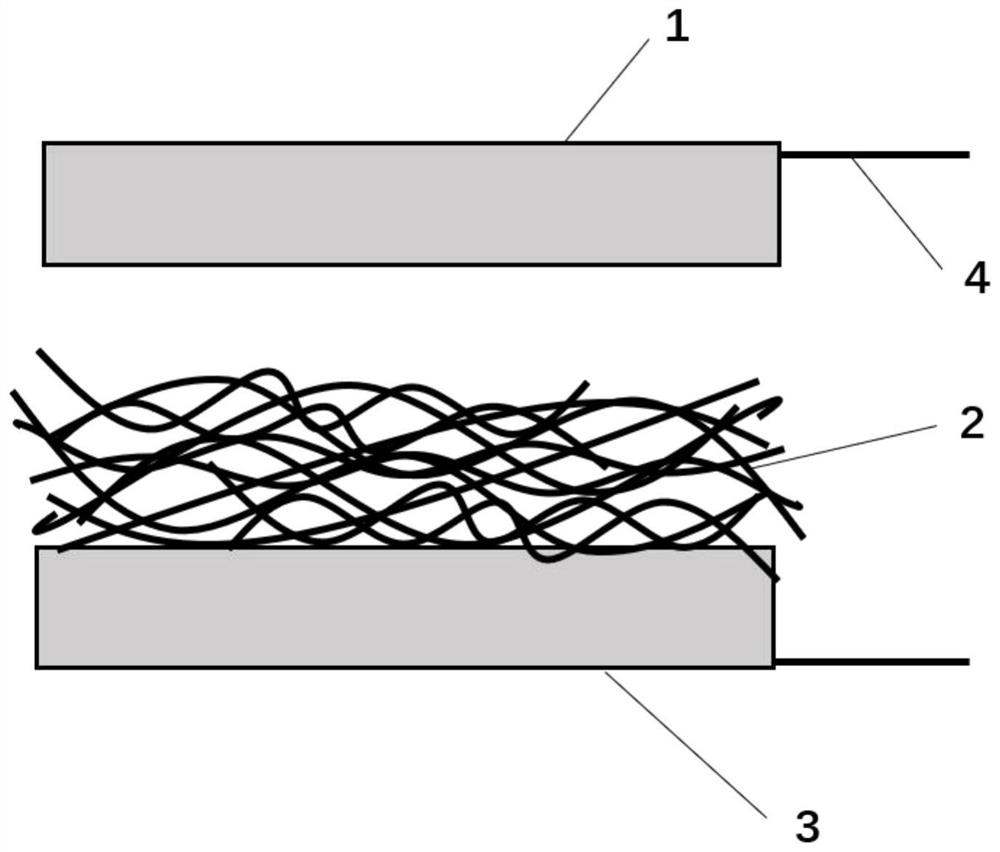

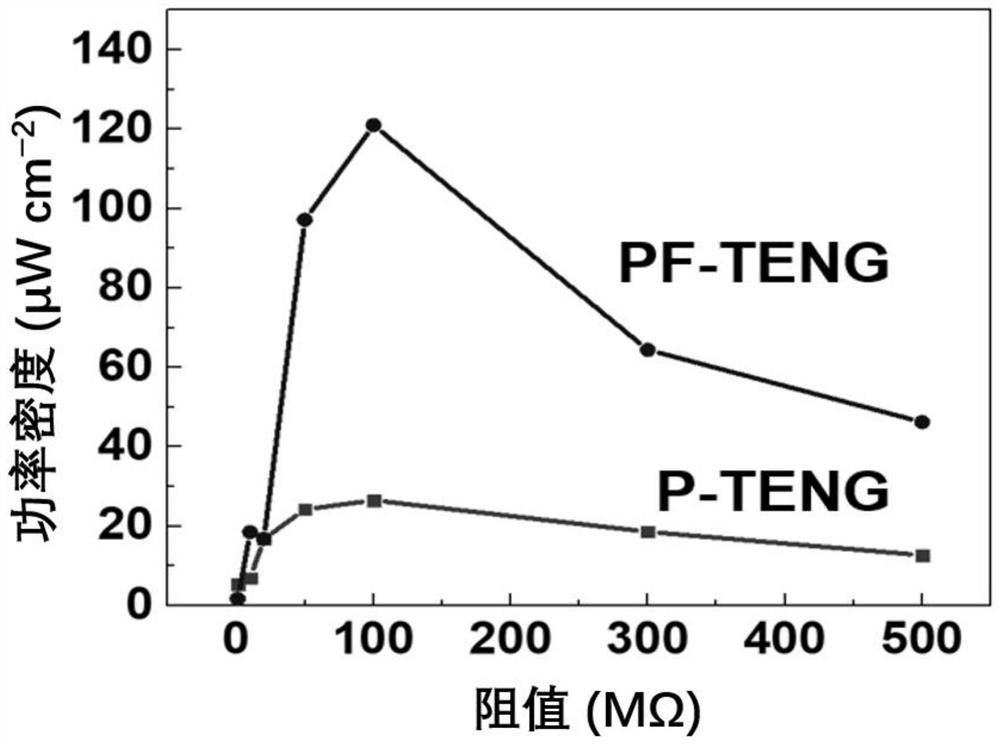

[0037] 9 mg of KUAST-8 powder was added to 3.28 mL of acetone and sonicated for 1 h to form a homogeneous suspension A. Solution B was prepared by dissolving 1.8 g of PVDF in 5 mL of DMF at 65°C. Subsequently, the above-mentioned suspension A and solution B were mixed and stirred uniformly to prepare spinning solution C. Fill the spinning solution C into a 10 mL syringe and install it on the propulsion pump, the propulsion rate is set to 20 μL / min, the distance between the syringe tip and the collecting plate is fixed at 15 cm, the applied voltage is set to 18 kV, and the spinning time is 30min, finally obtained the PVDF nanofiber composite film (thickness is 100μm) that has added KUAST-8, and its microscopic appearance is as follows figure 1 shown. Subsequently, the resulting nanofiber composite film was cut into 2 × 3 cm 2 Then use double-sided tape to paste aluminum foil on one side of the film as an electrode and use copper conductive glue to draw the current to obtain ...

Embodiment 2

[0039] 9 mg of KUAST-8 powder was added to 3.28 mL of acetone and sonicated for 30 min to form a homogeneous suspension A. Solution B was prepared by dissolving 1.8 g of PVDF in 5 mL of DMF at 65°C. Subsequently, the above-mentioned suspension A and solution B were mixed and stirred uniformly to prepare spinning solution C. Fill the spinning solution C into a 10 mL syringe and install it on the propulsion pump, the propulsion rate is set to 20 μL / min, the distance between the syringe tip and the collecting plate is fixed at 15 cm, the applied voltage is set to 18 kV, and the spinning time is 30min. The reduction of ultrasonic time affects the dispersion of F-MOF powder in acetone, which makes it difficult to uniformly disperse F-MOF in PVDF in the spinning solution, resulting in difficulty in forming nanofibers during the spinning process and failing to successfully prepare nanofiber composites. film.

Embodiment 3

[0041] 90 mg of KUAST-8 powder was added to 3.28 mL of acetone and sonicated for 1 h to form a homogeneous suspension A. Solution B was prepared by dissolving 1.8 g of PVDF in 5 mL of DMF at 65°C. Subsequently, the above-mentioned suspension A and solution B were mixed and stirred uniformly to prepare spinning solution C. Fill the spinning solution C into a 10 mL syringe and install it on the propulsion pump, the propulsion rate is set to 20 μL / min, the distance between the syringe tip and the collecting plate is fixed at 15 cm, the applied voltage is set to 18 kV, and the spinning time is After 30 minutes, a PVDF nanofiber composite film (100 μm in thickness) added with KUAST-8 was finally obtained. Subsequently, the resulting composite nanofiber film was cut into 2 × 3 cm 2 Then use double-sided tape to paste aluminum foil on one side of the film as an electrode and use copper conductive glue to draw the current to obtain the negative electrode of the friction nanogenerato...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com