High-strength stainless steel and manufacturing method thereof

A manufacturing method and stainless steel technology, applied in the field of high-strength stainless steel and its preparation, can solve the problems of reduced thermal processing performance, poor welding adaptability, edge cracks of duplex stainless steel strip, etc., and achieve the effect of reducing the occurrence of welding hot cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0090] A high-strength stainless steel, the composition of which contains in mass %,

[0091] C: 0.04 to 0.09% by mass,

[0092] Si: 1.5 to 2.5% by mass,

[0093] Mn: less than 1.0% by mass,

[0094] Cr: 13.0 to 15.0% by mass,

[0095] Ni: 6.0 to 7.0% by mass,

[0096] N: less than 0.010% by mass,

[0097] Mo: 0.6 to 1.0% by mass,

[0098] Cu: 0.6 to 1.0% by mass,

[0099] Ti: 0.3 to 0.8% by mass,

[0100] B: less than 0.03% by mass,

[0101] V: less than 0.3% by mass

[0102] P: less than or equal to 0.030% by mass,

[0103] S: less than or equal to 0.005% by mass,

[0104] The rest is Fe and unavoidable impurity elements;

[0105] Wherein, Cr+Mo+0.5Ti=Creq;

[0106] Ni+30*(C+N)+0.5Mn+0.25Cu=Nieq;

[0107] 1.4≤Creq / Nieq≤1.8.

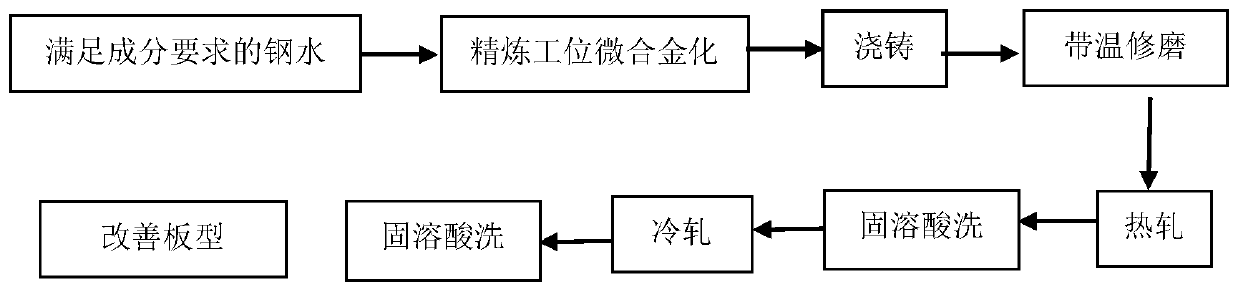

[0108] The present invention also provides a kind of manufacturing method of described high-strength stainless steel, comprises the following steps:

[0109] A. Select a steel slab that meets the composition requirements of the high-stren...

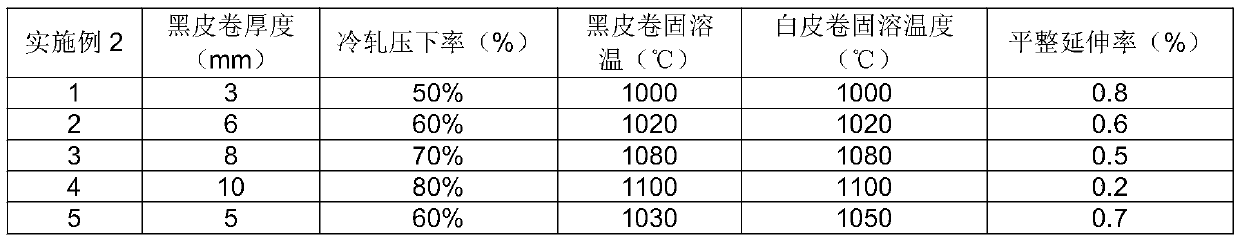

Embodiment 2

[0127] After the smelted molten steel is cast into a slab, it is fully ground at a certain temperature to remove the surface defects of the slab, and the temperature after the grinding is greater than 200°C. The chemical composition of the steel slabs is shown in Table 1.

[0128] The chemical composition of table 1 present embodiment steel slab

[0129] Example 2 C Si mn S P Cr Ni Cu Mo Ti N B V Creq / Nieq 1 0.04 1.5 0.9 0.005 0.03 13.0 6.7 0.6 0.6 0.3 0.01 0 0.3 1.56 2 0.045 1.7 0.5 0.002 0.023 14.1 6.9 0.8 0.8 0.35 0.01 0.001 0.2 1.68 3 0.055 1.8 0.4 0.001 0.028 14.0 6.7 0.84 0.7 0.38 0.007 0.002 0.1 1.66 4 0.09 1.8 0.8 0.003 0.025 15.0 7.5 1 0.8 0.5 0.008 0.003 0 1.45 5 0.06 1.75 0.5 0.001 0.027 13.5 7.1 0.7 0.75 0.4 0.004 0.002 0.24 1.50

[0130] The ground steel slab is heated in a heating furnace, hot rolled, solution pickled for black coils, cold ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com