Distillation extraction method for Maotai-flavor liquor

A Maotai-flavor liquor, distillation and extraction technology, applied in the field of brewing and distillation, can solve the problems of alcohol waste, uneven heating of raw materials, and poor wine quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

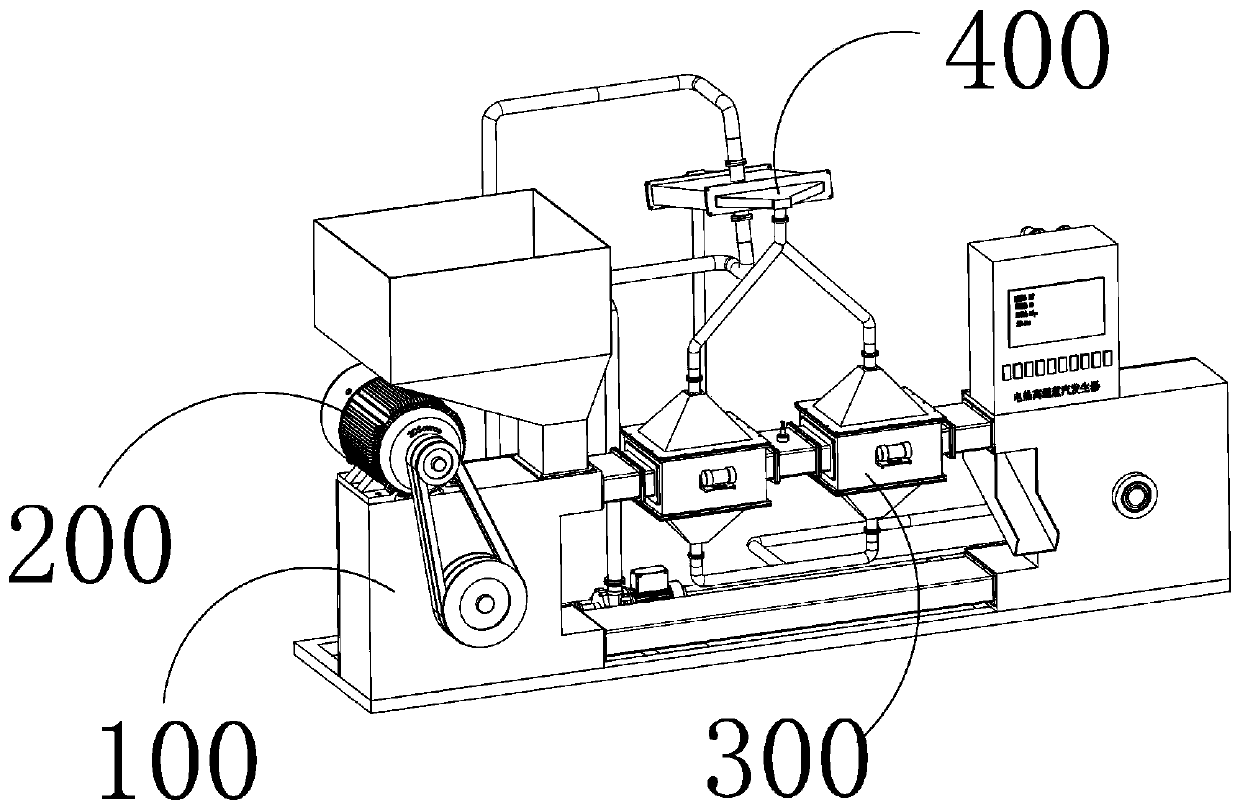

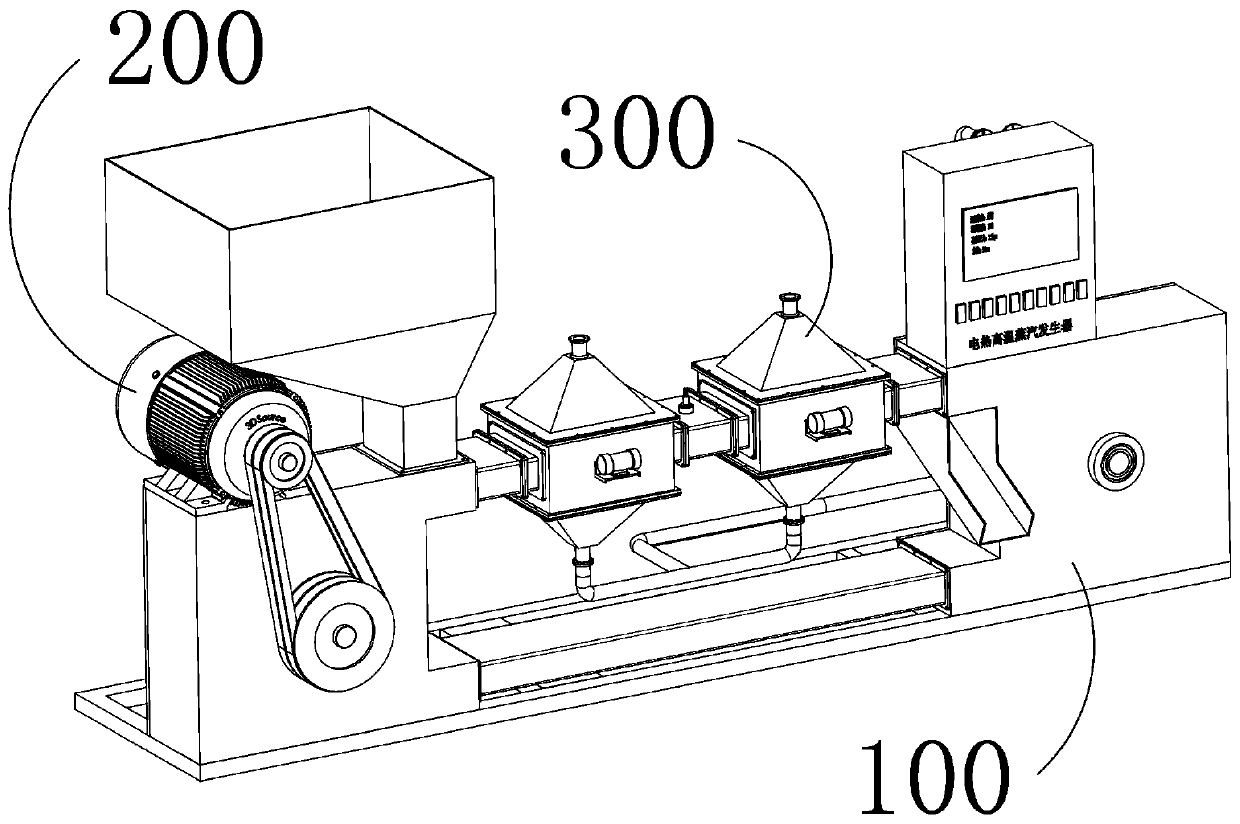

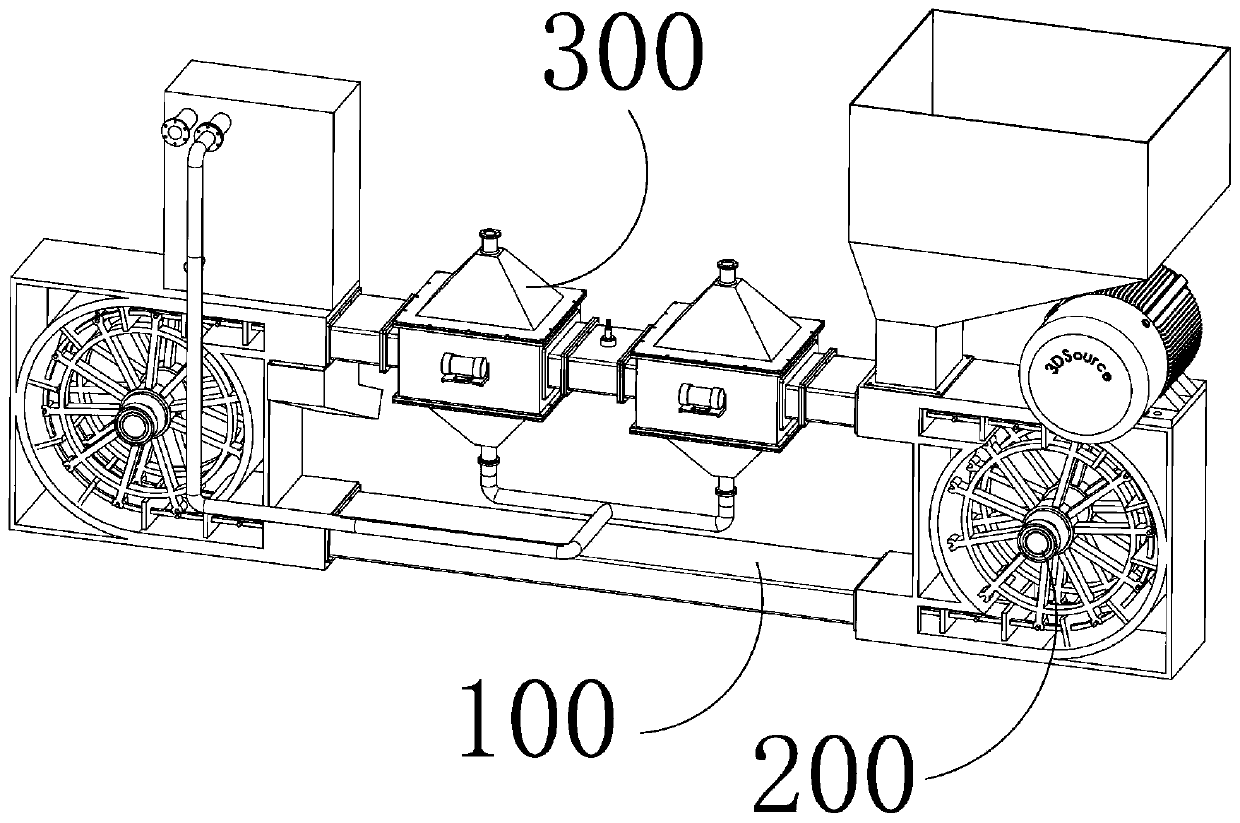

[0070] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0071] The distillation extraction method of Maotai-flavor liquor, the steps are:

[0072] (1) Distillation stage;

[0073] S1: The pipe chain conveying device 200 conveys the liquor to the distillation device 300 installed on the fixed frame body;

[0074] The distillation device 300 includes a distillation mechanism 310 and an electric high-temperature steam generator 330. The distillation mechanism 310 includes a distillation component. The distillation component includes a distillation shell 311 and a distillation inner shell 314. The distillation shell 311 is a rectangular shell structure with upper and lower ends open. And the distillation shell 311...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com