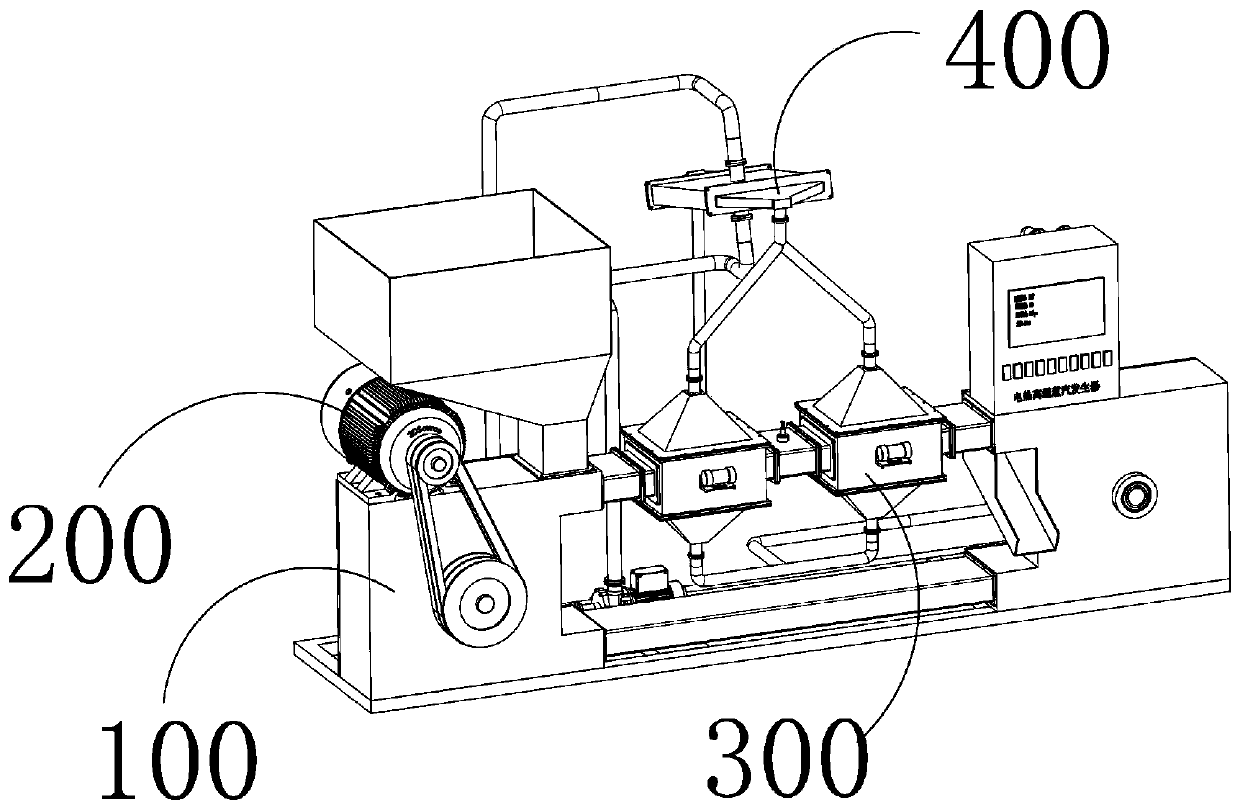

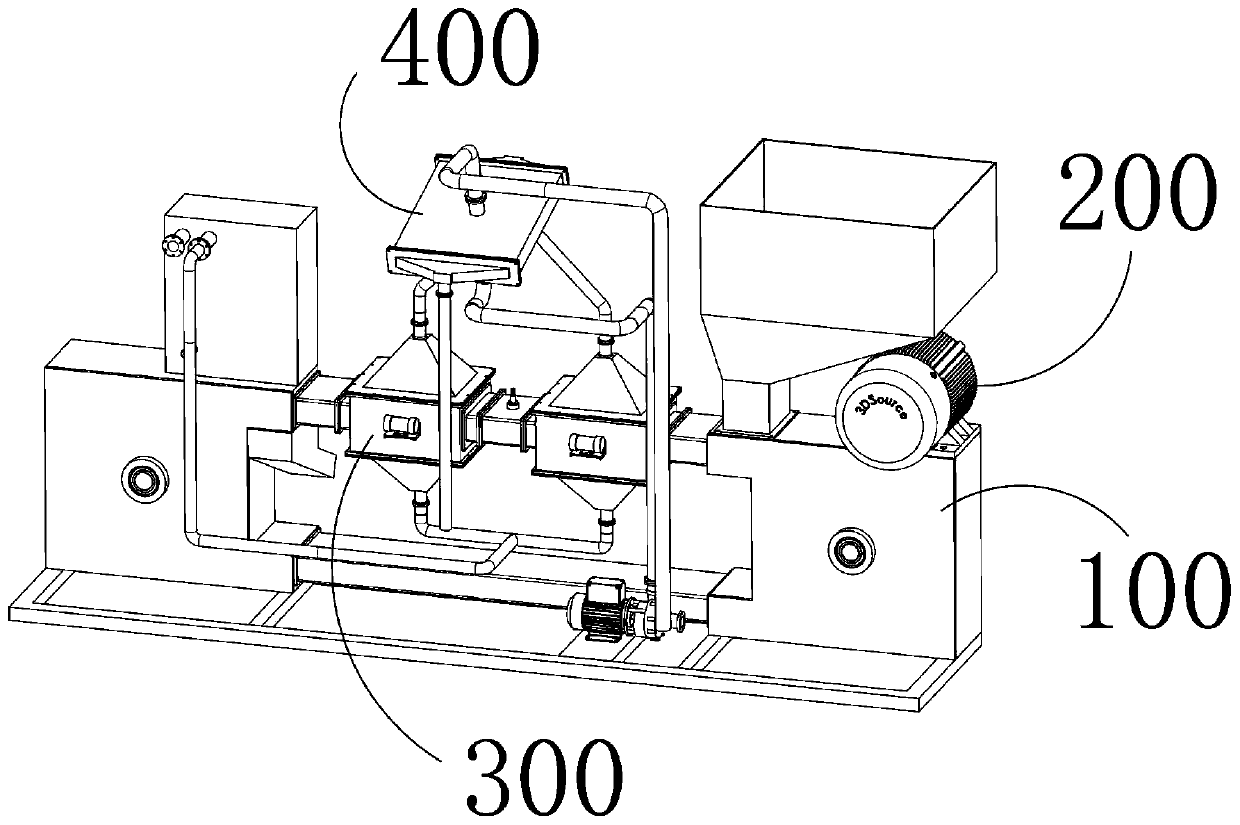

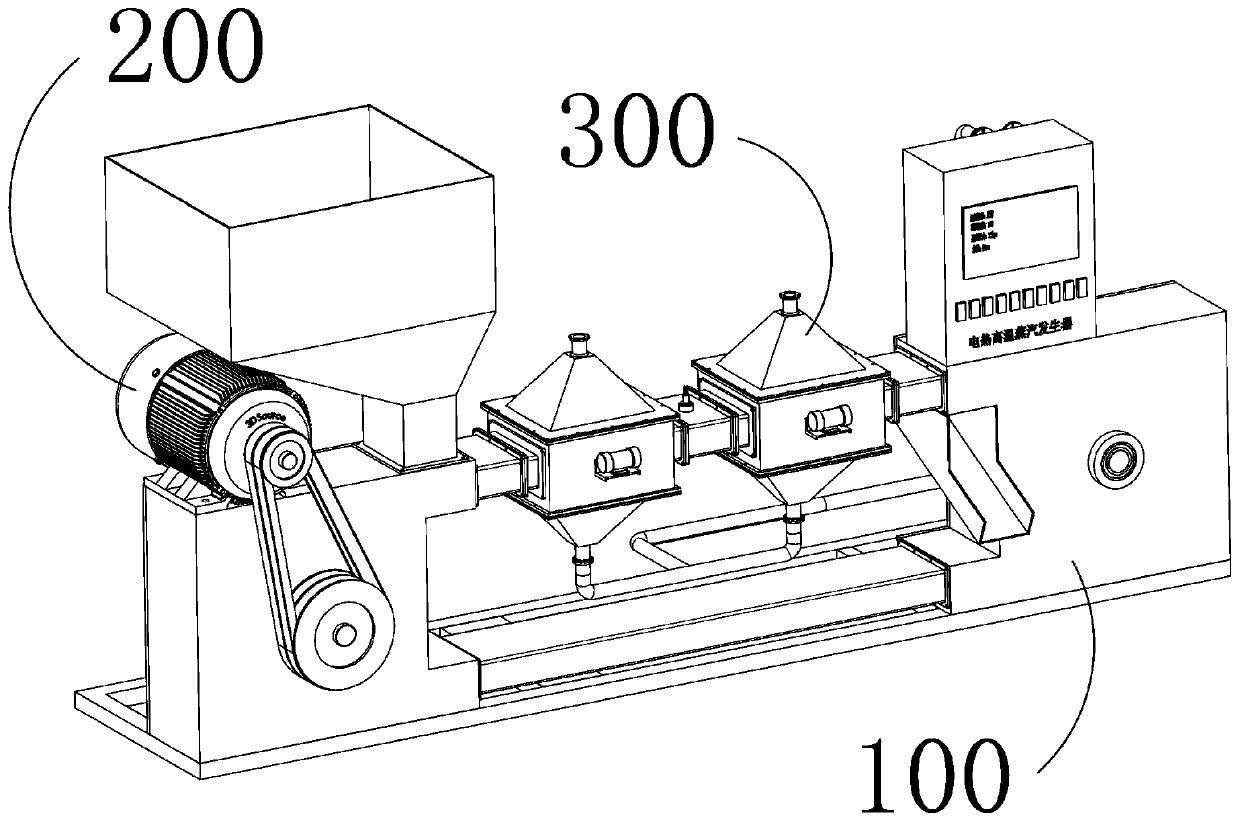

Distillation machine for brewing Maotai-flavor liquor

A sauce-flavored liquor and distillation machine technology, applied in the field of wine making, can solve problems such as difficult operation, complex structure, and a large amount of manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0074] The present invention has the advantage of carrying out alcohol distillation on wine material and then obtaining wine liquid in that it transports the wine material to the distillation device through the pipe chain transportation mode and transports the wine material waste residue in the distillation device away, and the wine material in the distillation device is There are two sets of components for distillation, so as to realize the double distillation of the wine material, so that the alcohol in the wine material will be completely distilled and volatilized, and the alcohol yield is higher. The entire distillation process is fully automated, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com