Driving main machine of electric lifting type clothes hanger

A lift-type, driving motor technology, which is applied in the direction of electric components, clockwork mechanisms, electrical components, etc., can solve the problems of the time lag of the driving motor stopping work, the consumption of wire ropes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

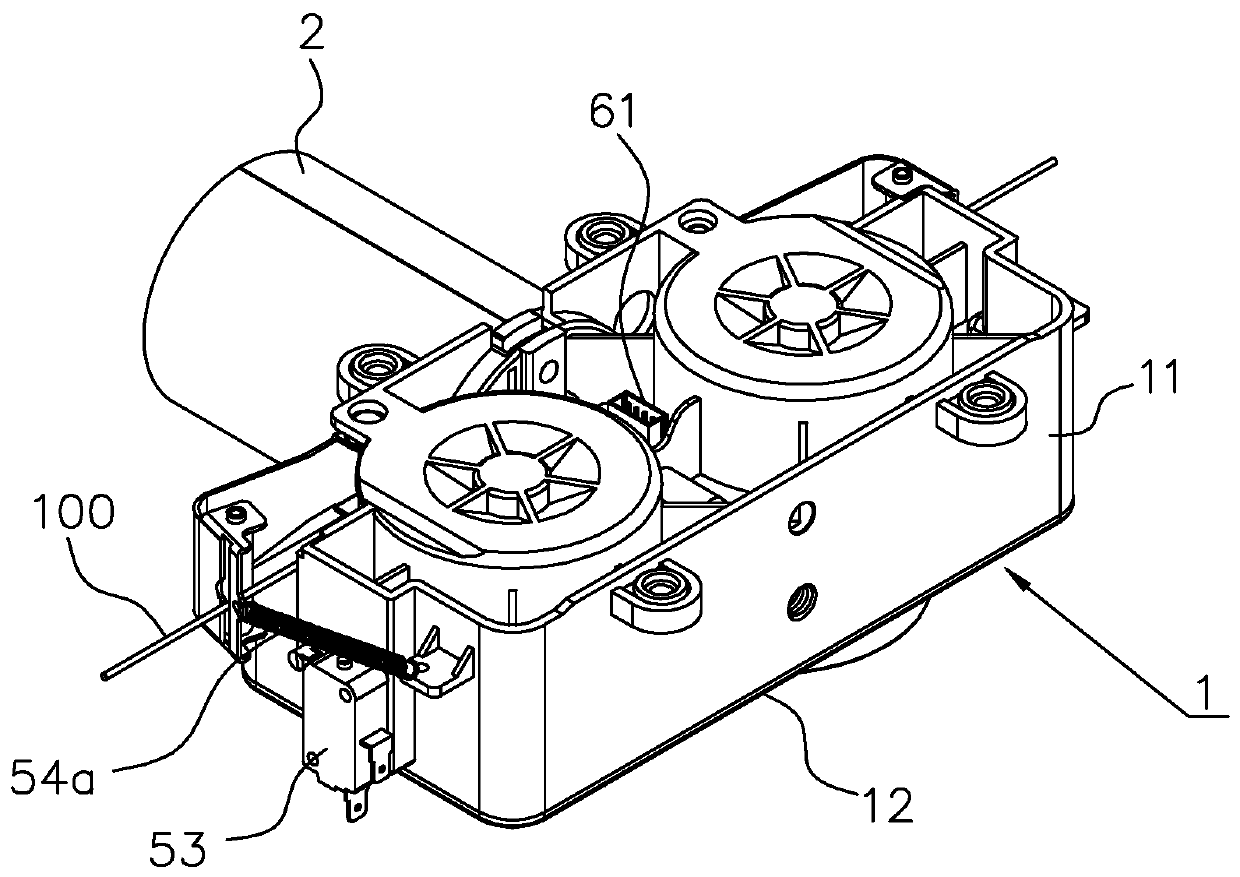

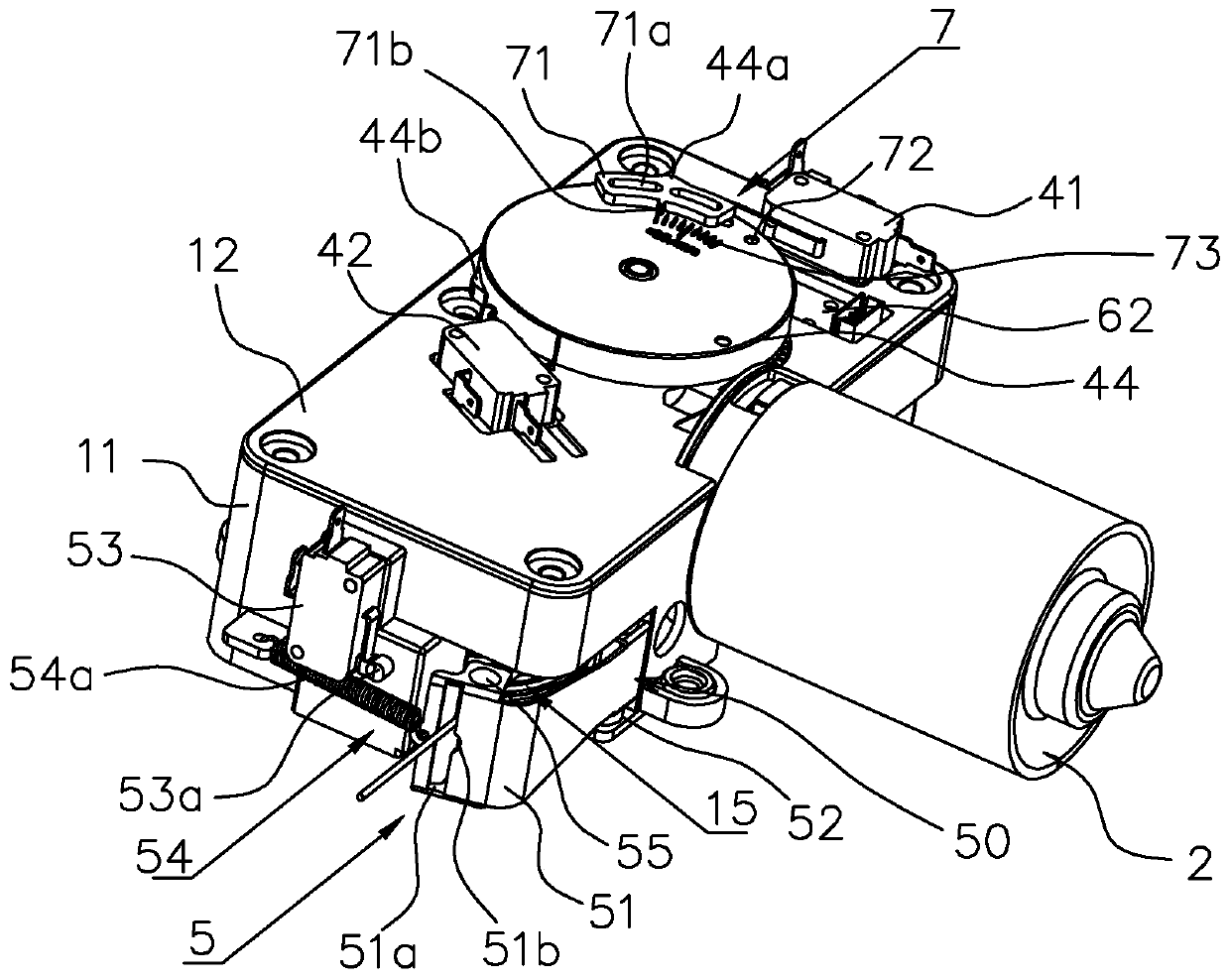

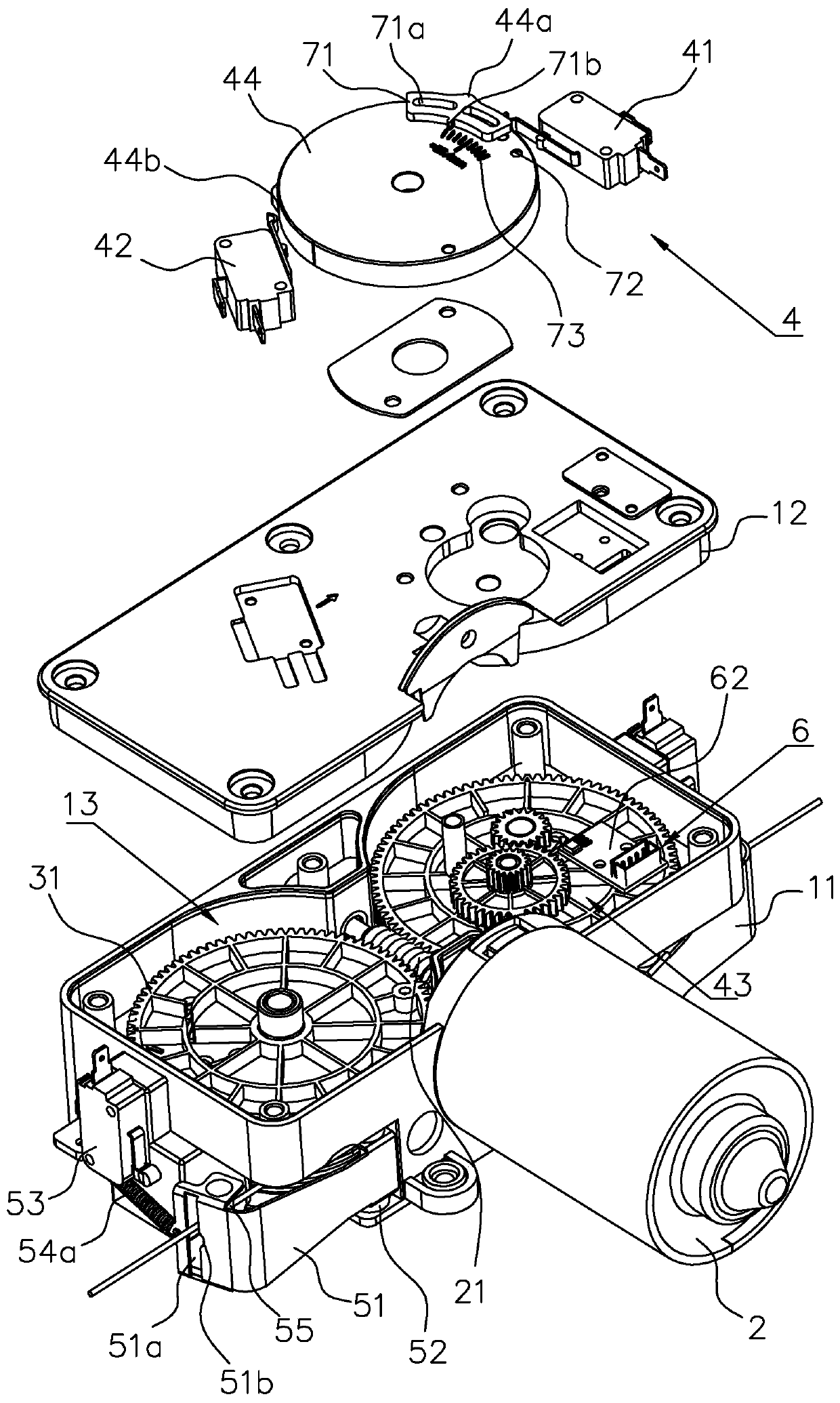

[0050] Such as figure 1 , figure 2 and image 3 As shown, the driving host of an electric lifting clothes drying rack in this embodiment includes a machine box 1, and the machine box 1 is composed of a box body 11 and a box cover 12, both of which are fixedly connected by bolts.

[0051] Two accommodating spaces 13 are symmetrically arranged in the box body 11, each accommodating space 13 is equipped with a reel 3, the central axis of the reel 3 is connected to the machine box 1 in rotation, and each reel 3 all have the worm gear 31 that is positioned at one end of reel 3.

[0052] One side of the box body 11 is fixedly installed with a drive motor 2 electrically connected to the electric control mechanism (not shown), the power shaft of the drive motor 2 is connected with the worm screw 21 arranged in the box body 11, and the The worm 21 meshes with the two worm wheels 31 respectively, and the driving motor 2 simultaneously drives the two reels 3 to rotate.

[0053] Such...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com