Novel automobile energy absorption box and preparation method thereof

A technology of energy-absorbing boxes and automobiles, which is applied to bumpers and other directions, can solve the problems of low specific energy absorption, weak energy-absorbing ability, and high cost of energy-absorbing boxes, and achieve improved energy-absorbing effects, strong energy-absorbing ability, and light weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

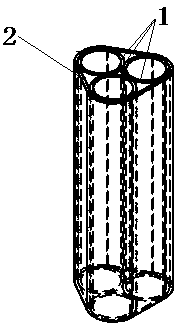

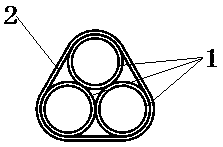

[0042] A new type of automobile energy-absorbing box, which includes a core body 1 and a wrapping layer 2; the core body 1 is obtained by rolling a composite unidirectional carbon fiber prepreg cloth into a cylindrical shape, and the composite unidirectional carbon fiber prepreg cloth is made of 6 layers of unidirectional carbon fiber prepregs are stacked and cured; the wrapping layer 2 is formed by stacking and curing 6 layers of unidirectional carbon fiber prepregs; the wrapping layer 2 wraps and fixes three cores 1 and adjacent cores 1 are close to each other; the layup sequence of the composite unidirectional carbon fiber prepreg is 0°, 0°, 90°, 90° cycle; the layup sequence of the wrapping layer 2 is 0°, 0° °, 90°, 90° cycle; the height and thickness of the composite unidirectional carbon fiber prepreg and the wrapping layer 2 are the same.

[0043] The preparation method of the novel automobile energy-absorbing box described in the present embodiment comprises the follow...

Embodiment 2

[0054] A new type of automobile energy-absorbing box, which includes a core body 1 and a wrapping layer 2; the core body 1 is obtained by rolling a composite unidirectional carbon fiber prepreg cloth into a cylindrical shape, and the composite unidirectional carbon fiber prepreg cloth is made of 8 layers of unidirectional carbon fiber prepreg are stacked and cured; the wrapping layer 2 is formed by stacking and curing 8 layers of unidirectional carbon fiber prepreg; the wrapping layer 2 wraps and fixes three cores 1 and adjacent cores 1 are close to each other; the layup sequence of the composite unidirectional carbon fiber prepreg is 0°, 90°, 0°, 90° cycle; the layup sequence of the wrapping layer 2 is 0°, 90° °, 0°, 90° cycle; the height and thickness of the composite unidirectional carbon fiber prepreg and the wrapping layer 2 are the same.

[0055] The preparation method of the novel automobile energy-absorbing box described in the present embodiment comprises the followin...

Embodiment 3

[0066] A new type of automobile energy-absorbing box, which includes a core body 1 and a wrapping layer 2; the core body 1 is obtained by rolling a composite unidirectional carbon fiber prepreg cloth into a cylindrical shape, and the composite unidirectional carbon fiber prepreg cloth is made of 10 layers of unidirectional carbon fiber prepregs are stacked and cured; the wrapping layer 2 is formed by stacking and curing 10 layers of unidirectional carbon fiber prepregs; the wrapping layer 2 wraps and fixes three cores 1 and adjacent cores 1 are close to each other; the layup sequence of the composite unidirectional carbon fiber prepreg is 0°, 0°, 45°, 45°, 90°, 90° cycle; the layup sequence of the wrapping layer 2 It is cycled according to 0°, 0°, 45°, 45°, 90°, 90°; the height and thickness of the composite unidirectional carbon fiber prepreg cloth and the wrapping layer 2 are the same.

[0067] The preparation method of the novel automobile energy-absorbing box described in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com