A fast filament feeding device for fdm type 3d printing filament

A 3D printing and fast technology, applied in the field of 3D printing, can solve the problems of unable to move at a uniform speed and low universality, so as to improve the efficiency of spacing adjustment, avoid jamming or bending, and improve universality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

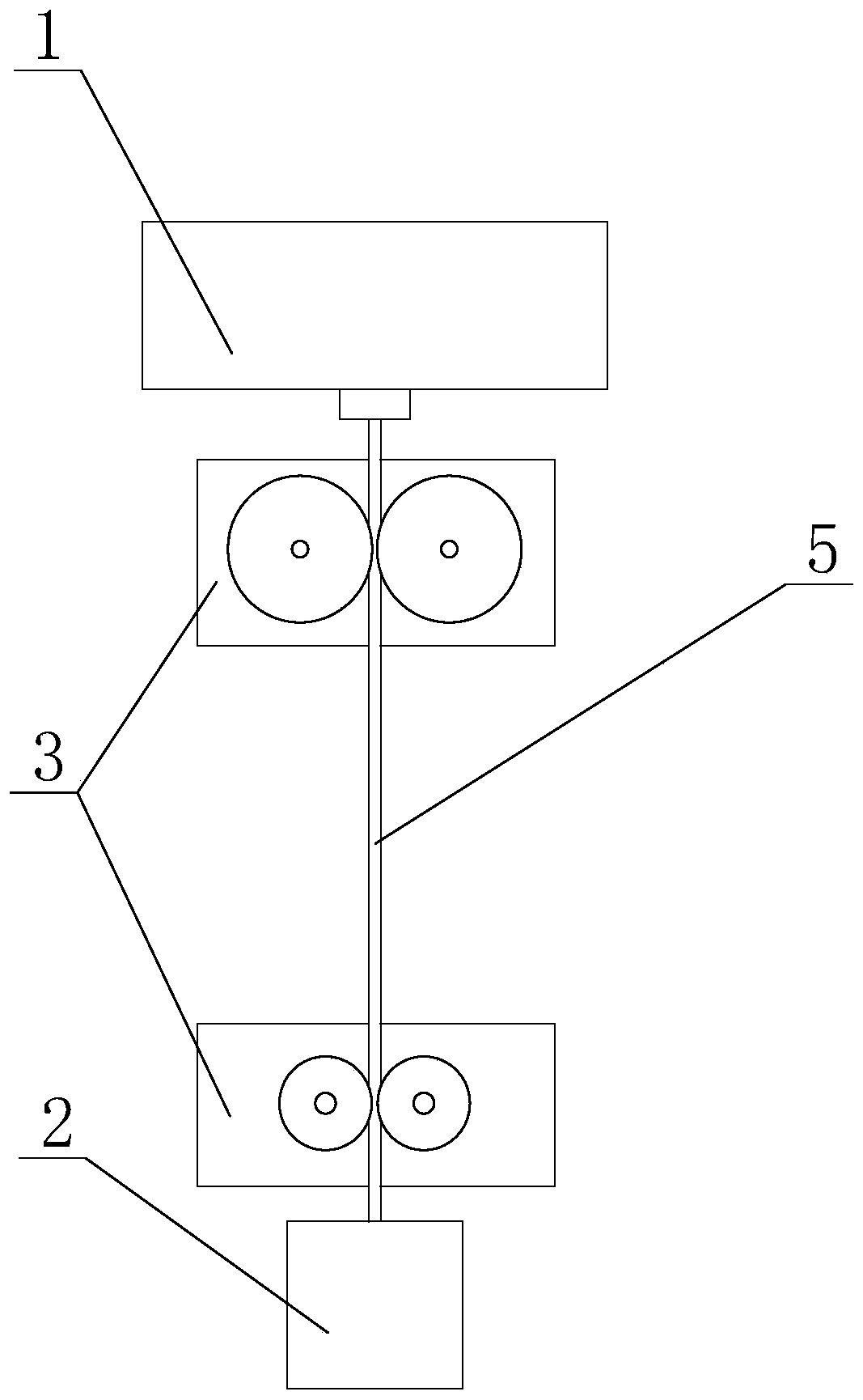

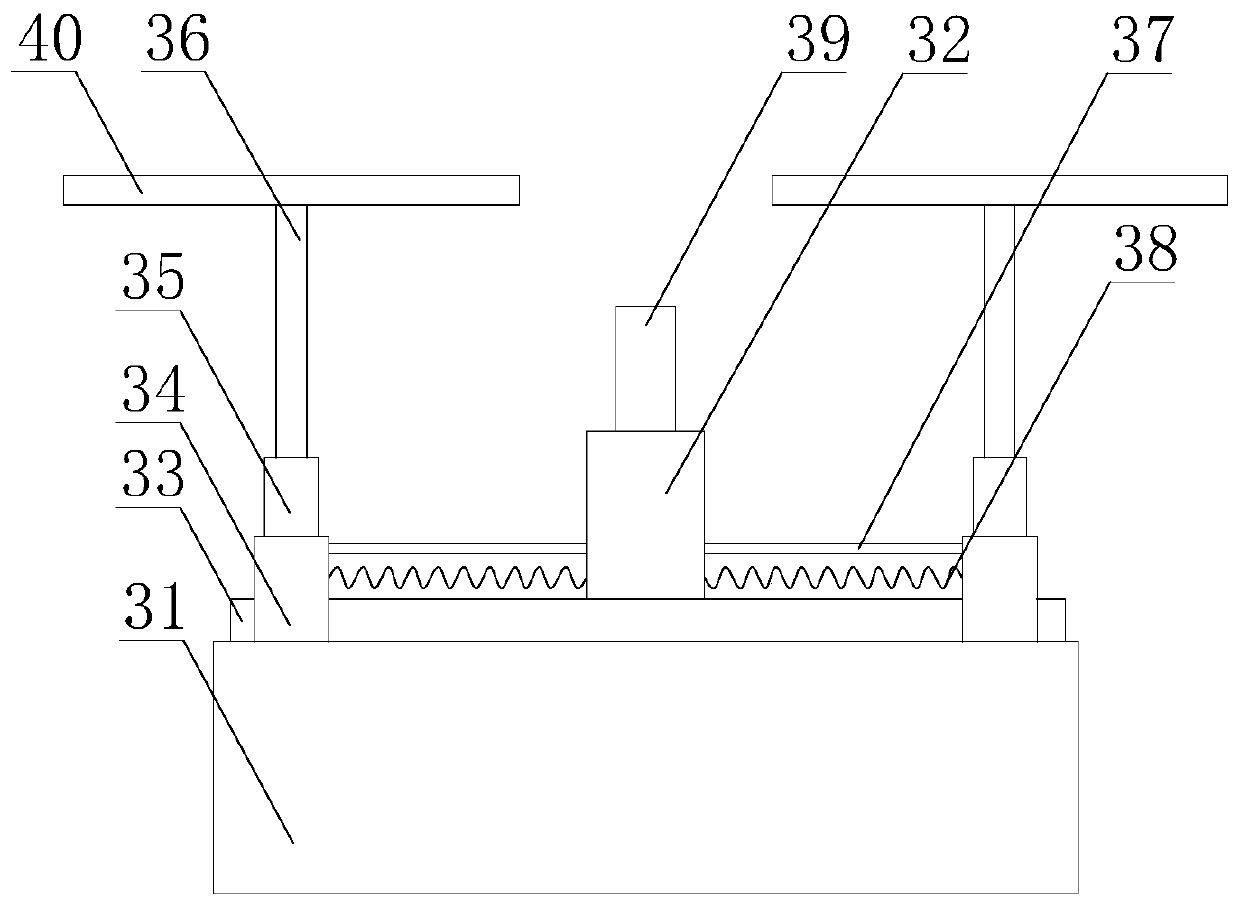

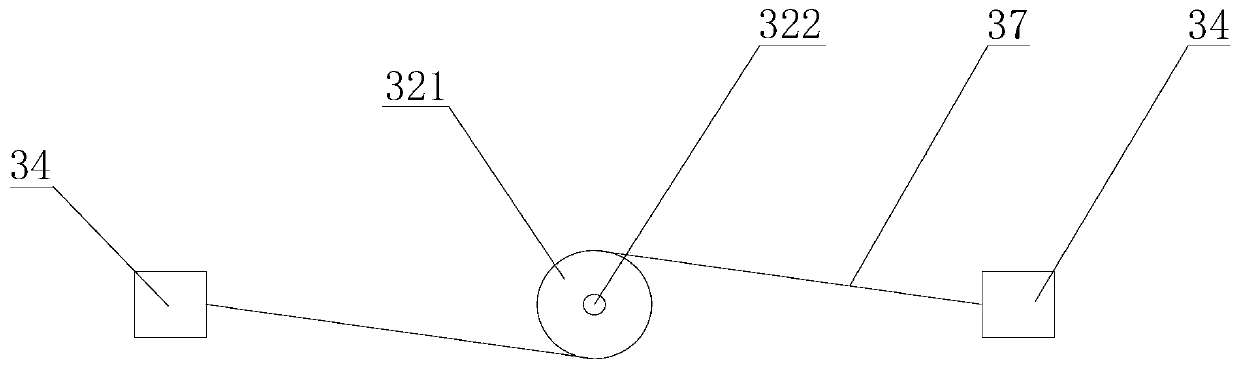

[0038] like Figure 1 to Figure 4 A fast filament feeding device for FDM type 3D printing is shown, which includes a first feeding mechanism close to the feeding tank 1 and a second feeding mechanism close to the nozzle 2. The structures of the first and second feeding mechanisms are basically the same, both It includes a base 31 located between the feeding tank 1 and the spray head 2, the base 31 is provided with a rail 33, and the rail 33 is slidably provided with two sliders 34, and the slider 34 is provided with a first driving device 35, the output end of the first driving device 35 is connected to the wire feeding reel 40 through the first rotating shaft 36, the first driving device 35 is used to drive the wire feeding reel 40 to rotate, the distance between the two wire feeding reels (40) Matches the diameter of the wire 5; the base 31 is provided with a distance adjustment mechanism 32, and the distance adjustment mechanism 32 is used to adjust the distance between the...

Embodiment 2

[0044] On the basis of Example 1, such as Figure 5 As shown, along the circumferential direction of the wire feeding reel 40, an annular groove 41 is provided on the side of the wire feeding reel 40; a wire feeding ring 42 is arranged in the annular groove 41, and the wire feeding ring 42 is made of a flexible material to make.

[0045] In some embodiments, the wire feeding ring 42 is made of nitrile rubber or silicon rubber.

[0046] The above setting not only prevents the wire from moving in the vertical direction during the transmission process, but also increases the contact area between the wire and the wire feeding ring in the annular groove, and the higher friction coefficient of the rubber improves the feeding speed. The friction between the wire loop and the wire significantly improves the transmission efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com