Manufacturing equipment for ceramic fishing net pendant

A technology for manufacturing equipment and fishing nets, applied in the field of mechanical processing, can solve the problems of increased labor costs, labor consumption, high scrap rate, etc., and achieve the effects of saving labor costs, improving production efficiency, and rigorous design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

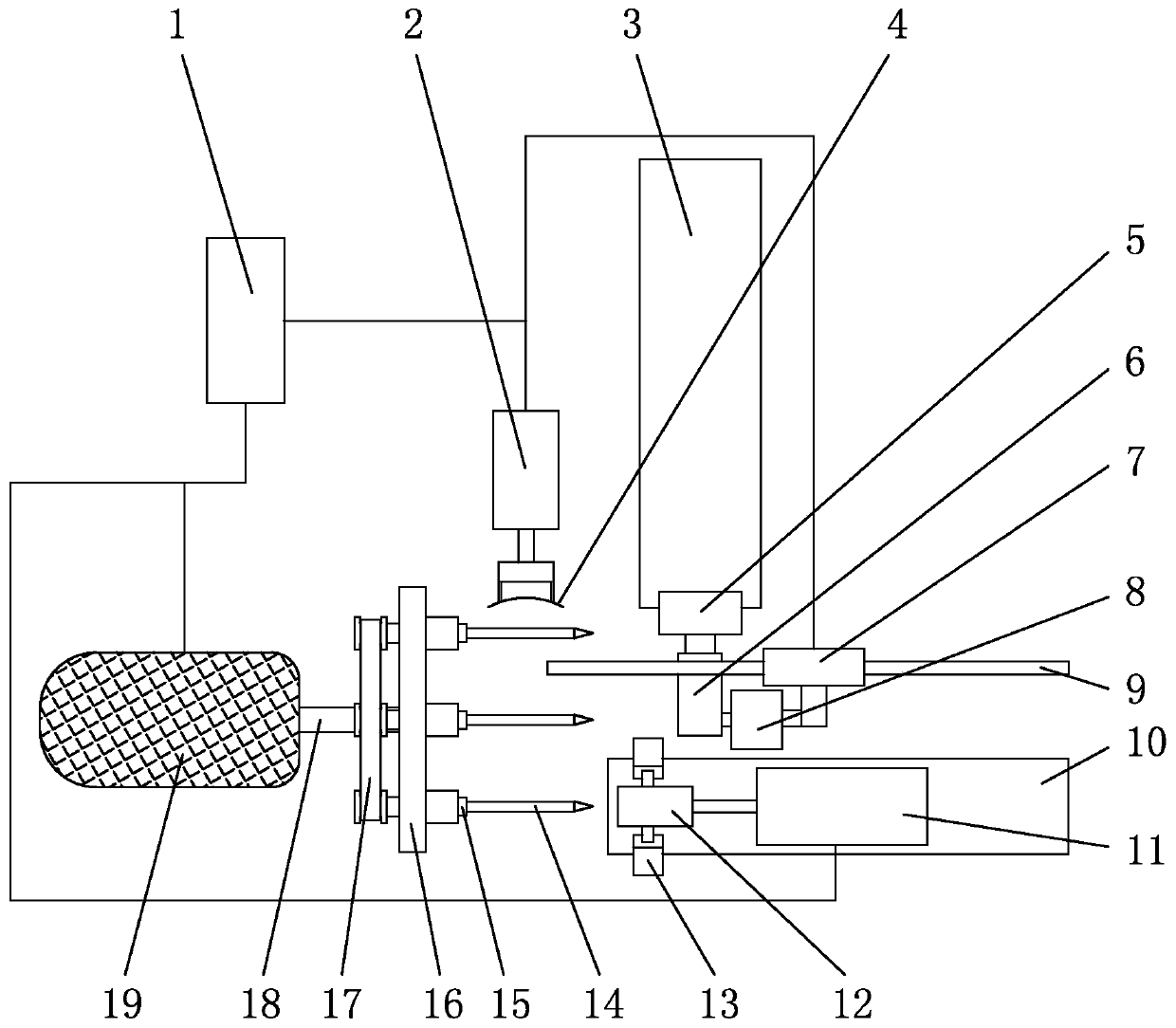

[0028] Such as Figure 1~4 As shown, a ceramic fishing net pendant manufacturing equipment includes a numerical control table 1, and the numerical control table 1 is respectively connected with a station plate system, a blank material clamping system, an arc processing system, and a head and tail processing system;

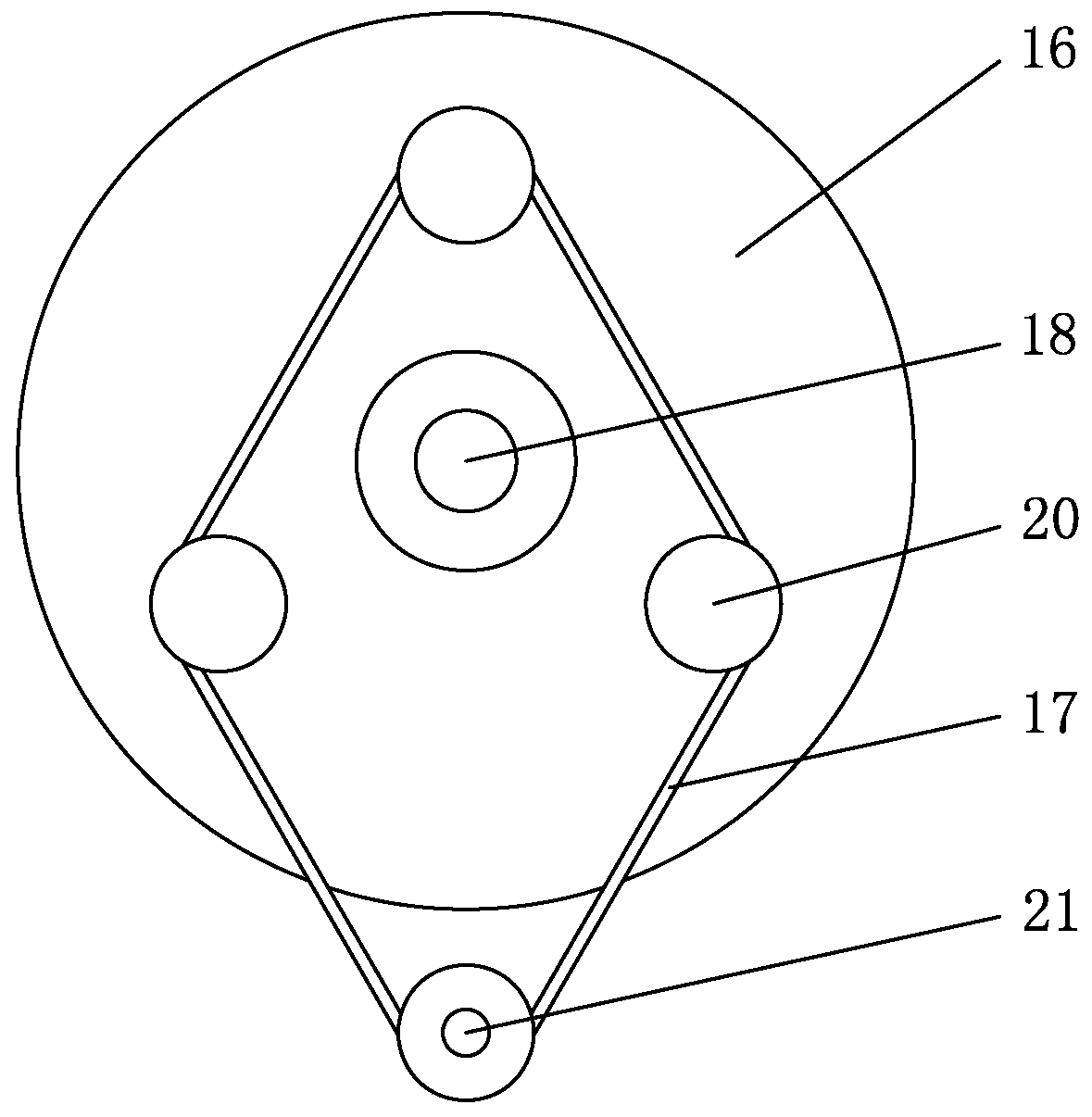

[0029] The station disk system comprises a station disk motor 19 and a station disk 16, the station disk motor 19 and the station disk 16 are connected by an interlocking shaft 18, and the station disk 16 is provided with three puncture rods 14, and the end of the puncture rod 14 is provided with There are transmission wheels 20, and three transmission wheels 20 are connected with the motor wheel 21 of the transmission belt motor through the transmission belt 17, and the puncture rod 14 is provided with a file head cutter 15;

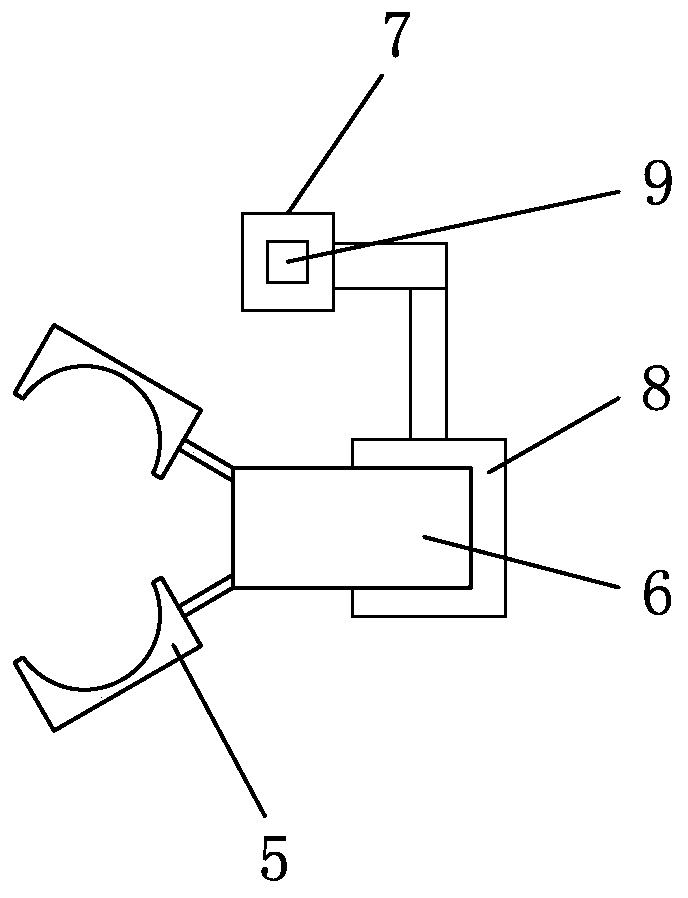

[0030] The billet cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com