Movable siphonal water decanter

A mobile, decanting technology, applied in the direction of aerobic and anaerobic treatment, can solve the problem of equipment waste, achieve the effect of reducing investment costs, rigorous design, and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

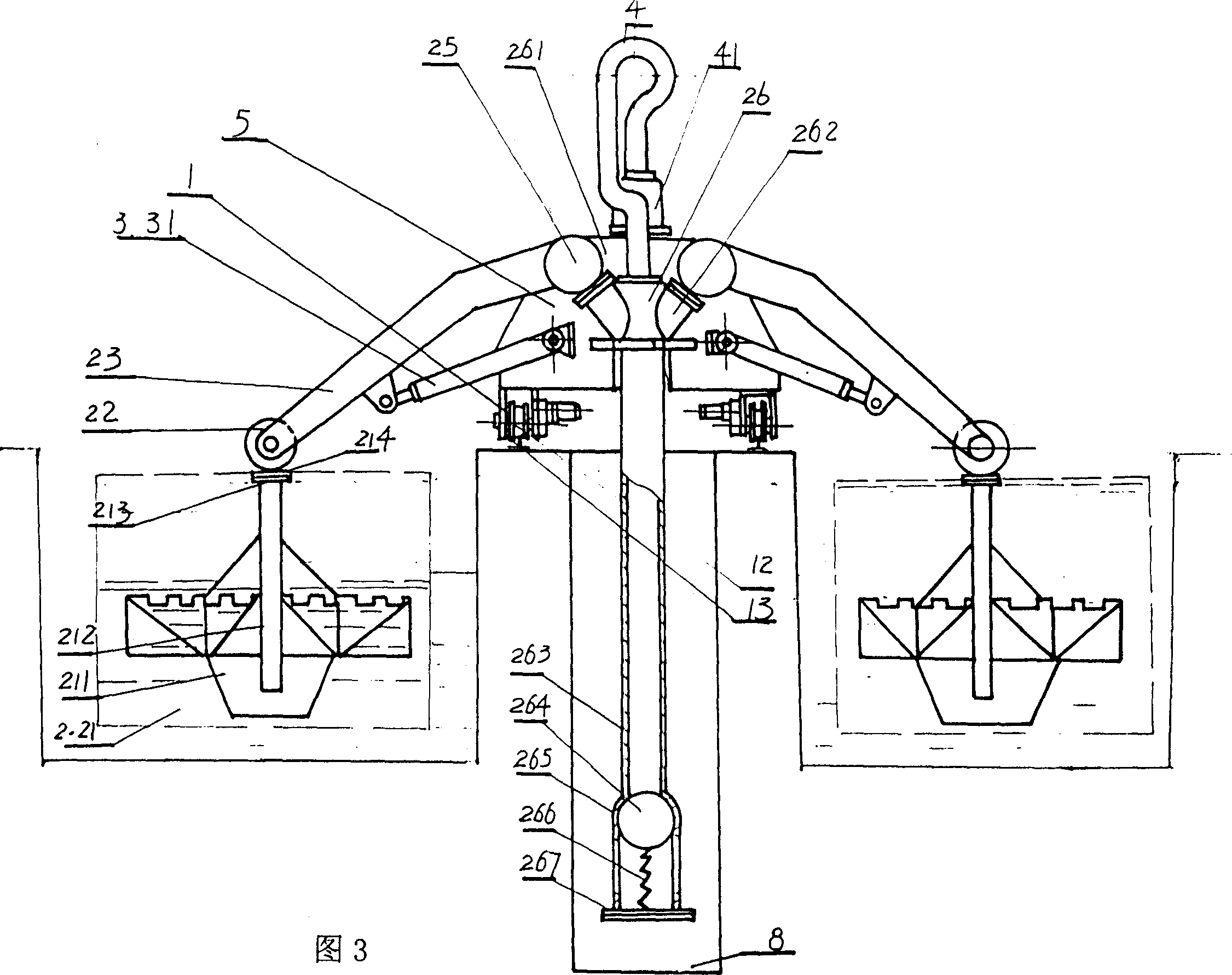

[0043] This embodiment is a dual-arm mobile siphon decanting machine. A set of decanter baskets 21 are symmetrically arranged on the left and right sides of the frame 5, and the swing arm 23 connected to the decanter basket 21, the water supply rotary joint 22, and the water supply The rotary joint 25 and the hydraulic mechanism 3 are all correspondingly configured. Its specific structure sees Fig. 3, Figure 4 .

[0044] The mobile siphon decanter includes a traveling mechanism 1, a decanting mechanism 2, a lifting mechanism, a siphon mechanism 4, a control mechanism and a frame 5. Its water decanting mechanism 2 is connected with siphon mechanism 4, lifting mechanism, and water decanting mechanism 2, siphon mechanism 4, lifting mechanism and control mechanism are all contained on the frame 5; The lifting mechanism of the embodiment adopts the hydraulic mechanism 3, the hydraulic mechanism 3 lifts the decanting mechanism 2, and the control mechanism controls the decanting m...

Embodiment 2

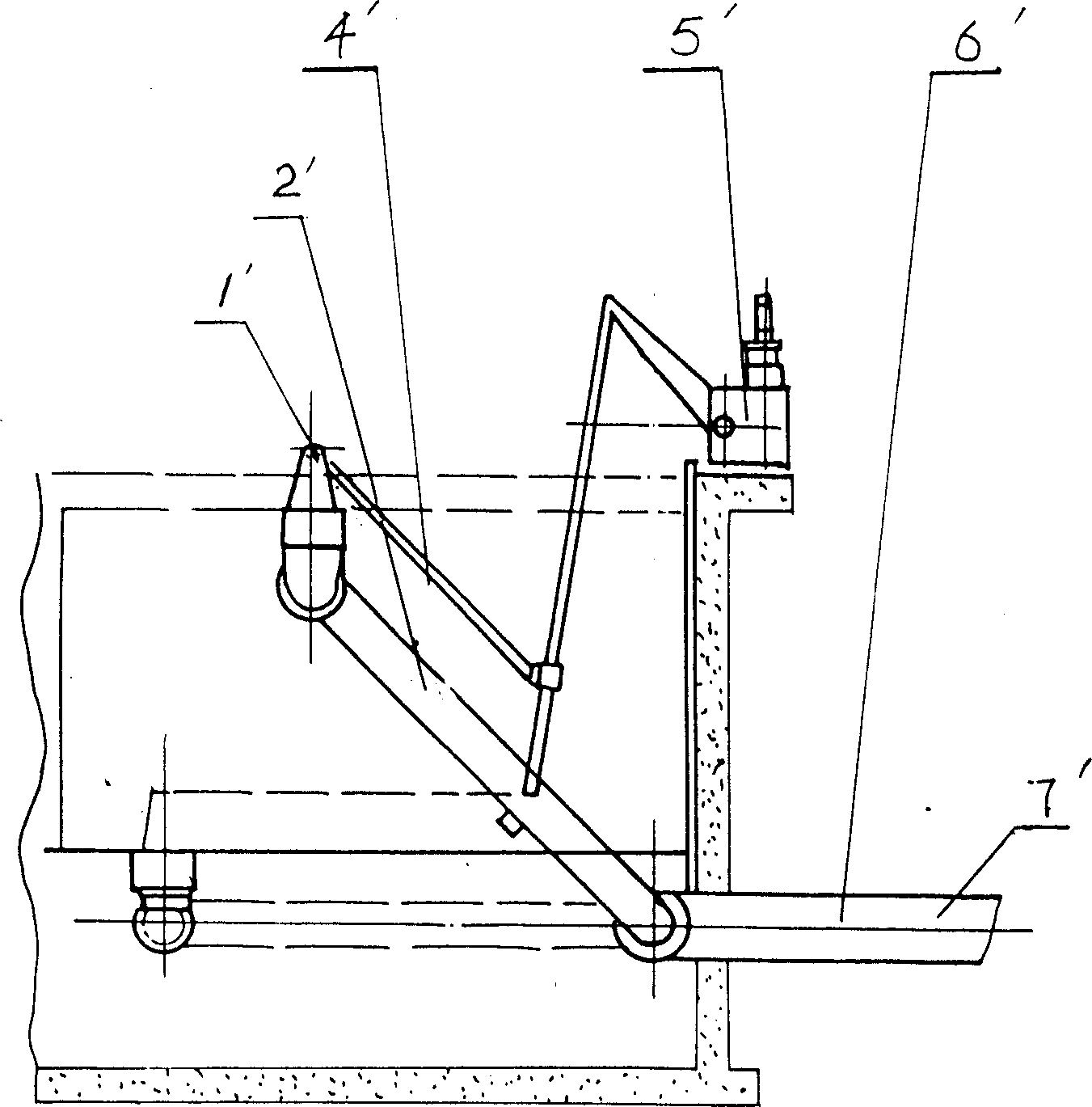

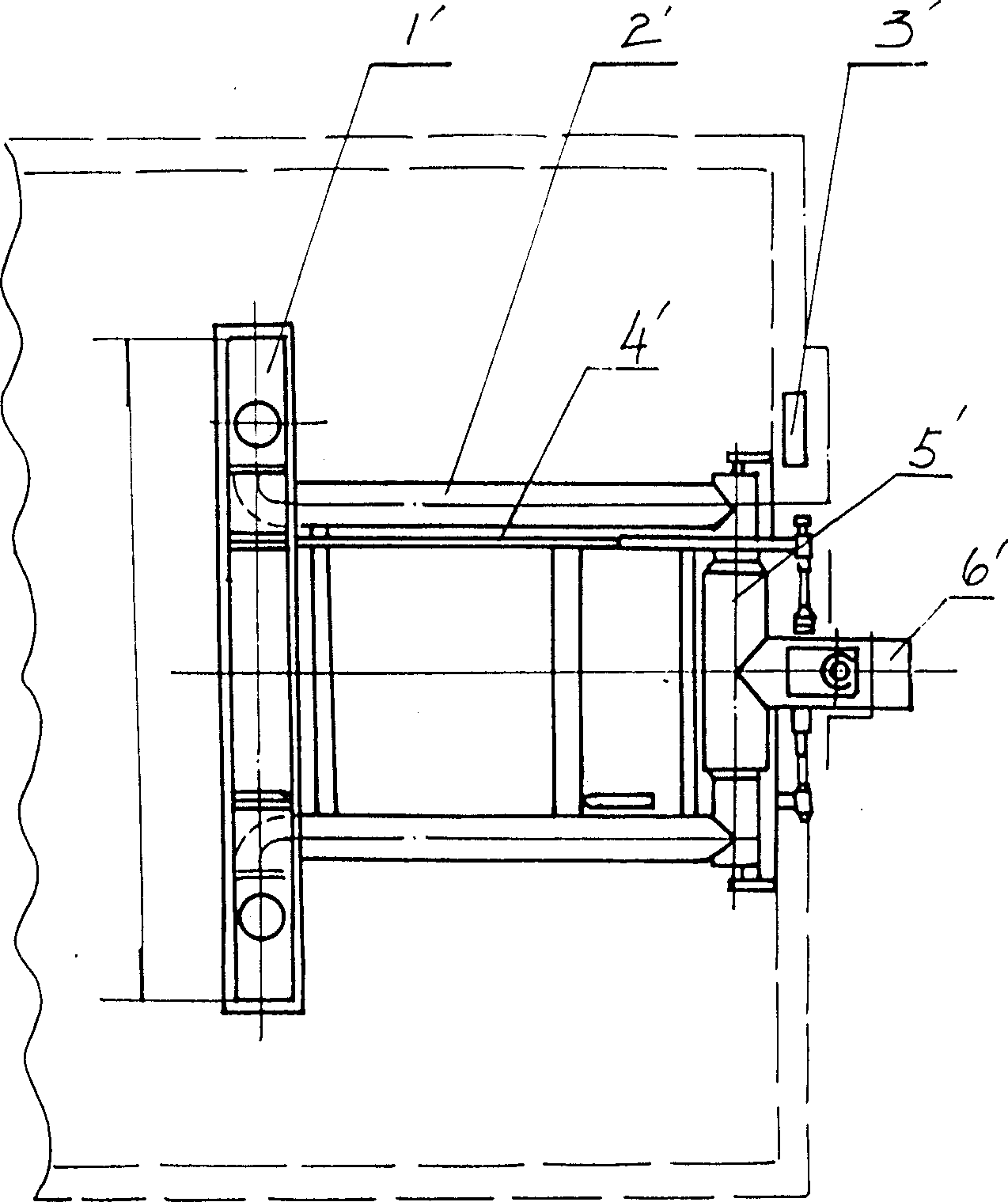

[0064] This embodiment is a single-arm mobile siphon decanter, its structure see Figure 12 , Figure 13.

[0065] Mobile single-arm siphon decanting machine, its decanting basket 21 is equipped with a set on one side of the frame 5, and the swing arm 23 connected to the decanting basket 21, the water supply rotary joint 22, the sewage rotary joint 25, Lower support hinge seat 24 and hydraulic mechanism 3 are all corresponding configurations, only obliquely following a lower water branch pipe 262 on the lower straight pipe 263, and the counterweight mechanism 7 is configured on the other side of the frame 5. The counterweight mechanism 7 is composed of mutually matching counterweights, fixing screws 71 and counterweight moving rails 72 . The counterweight of the present embodiment adopts the counterweight iron 70, and the counterweight moving rail 72 is integrated with the frame 5, but because of the needs of the counterweight, it must extend outward for a section so that the ...

Embodiment 3

[0069] This embodiment is a single-arm rotary mobile siphon decanter, the structure of which is shown in Figure 14 and Figure 15.

[0070] The single-arm rotary mobile siphon decanter refers to a single-arm but with dual functions of rotation and movement. It can complete all the decanting work that a single-arm or double-arm mobile siphon decanter can do. The mechanism settings of the water machine are different.

[0071] The most important thing about the rotary decanter is that there are two major parts of the rotary platform 62 and the rotary drive mechanism 63, and the frame is the rotary frame 6. The decanting basket 21 of the decanting machine is equipped with a set on one side of the rotating frame 6, and the rotating swing arm 27 connected with the decanting hanging basket 21, the water supply rotating joint 22, the rotating launching rotating joint 29, the rotating lower branch The hinge base 28 and the hydraulic mechanism 3 are all correspondingly configured, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com