Zoned material release finishing barrel and work method thereof

A material release and finishing technology, which is applied in the field of zonal material release and finishing barrels, can solve the problems of excess abrasives, single structure of finishing barrels, and inability to finely grind workpieces, so as to avoid excess abrasives and improve the efficiency of finishing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

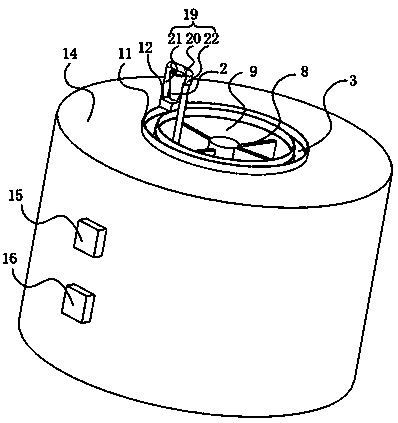

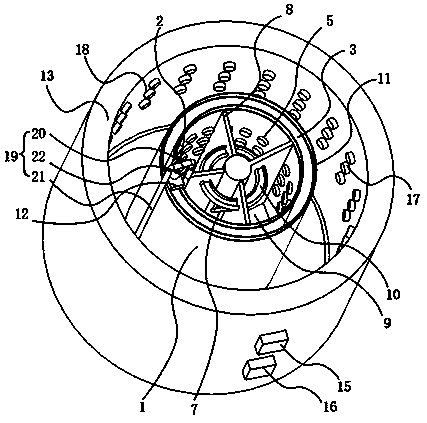

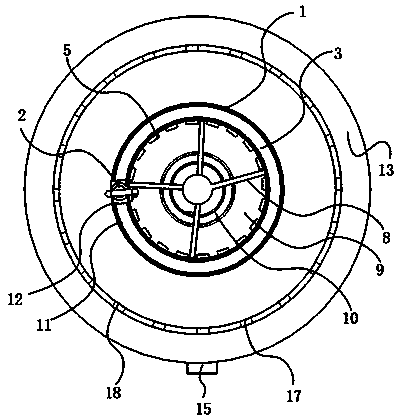

[0035] Please refer to Figure 1-5 . The present embodiment provides a kind of zonal material release light decoration barrel, which includes a rough grinding barrel 1, and the light decoration barrel also includes a discharge hopper 2, a storage bin 3, a material pump 4, a material injection valve 5, a PLC controller 6 and a turning Mechanism 7, the storage bin 3 is arranged outside the coarse grinding barrel 1, the release hopper 2 is erected above the storage bin 3 and communicated with the storage bin 3, and the material pump 4 is arranged on the storage bin 3 Inside the silo 3 and electrically connected to the material injection valve 5, the material injection valve 5 is multiple and the ring is set on the inner wall of the coarse grinding barrel 1; the coarse grinding barrel 1 is provided with a plurality of baffles 8 , the baffle plate 8 divides the rough grinding bucket 1 into a plurality of finishing areas 9, and the inner wall of the rough grinding bucket 1 of each ...

Embodiment 2

[0048] Please refer to Figure 1-5 . This embodiment provides a kind of zonal material release light decoration bucket, except for the content disclosed in the first embodiment, the light decoration bucket also includes a fine grinding bucket 13 sleeved outside the rough grinding bucket 1, and the fine grinding bucket 13 A sealed bucket cover 14 is arranged on it. The light decoration barrel also includes a shot blasting machine 15 and a refrigerator 16 arranged on the outside of the fine grinding barrel 13, and the PLC controller 6 is connected with the shot blasting machine 15 and the refrigerator 16 respectively; A plurality of liquid injection valves 17 and shot blasting valves 18 are arranged in the ring, the liquid injection valves 17 are connected to the refrigerator 16 , and the shot blasting valves 18 are connected to the shot blasting machine 15 .

[0049] Wherein, the decorative barrel also includes a feed pipe 19 erected above the storage bin 3, the feed pipe 19 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com