Anti-inverse disc inclined hole drilling tool and machining method thereof

An oblique hole and anti-reverse technology, which is applied in metal processing equipment, manufacturing tools, boring/drilling, etc., can solve the problems of high processing cost of machining centers, unsuitable for mass production, and long machine tool debugging time. High efficiency, reduced equipment investment, and reduced processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

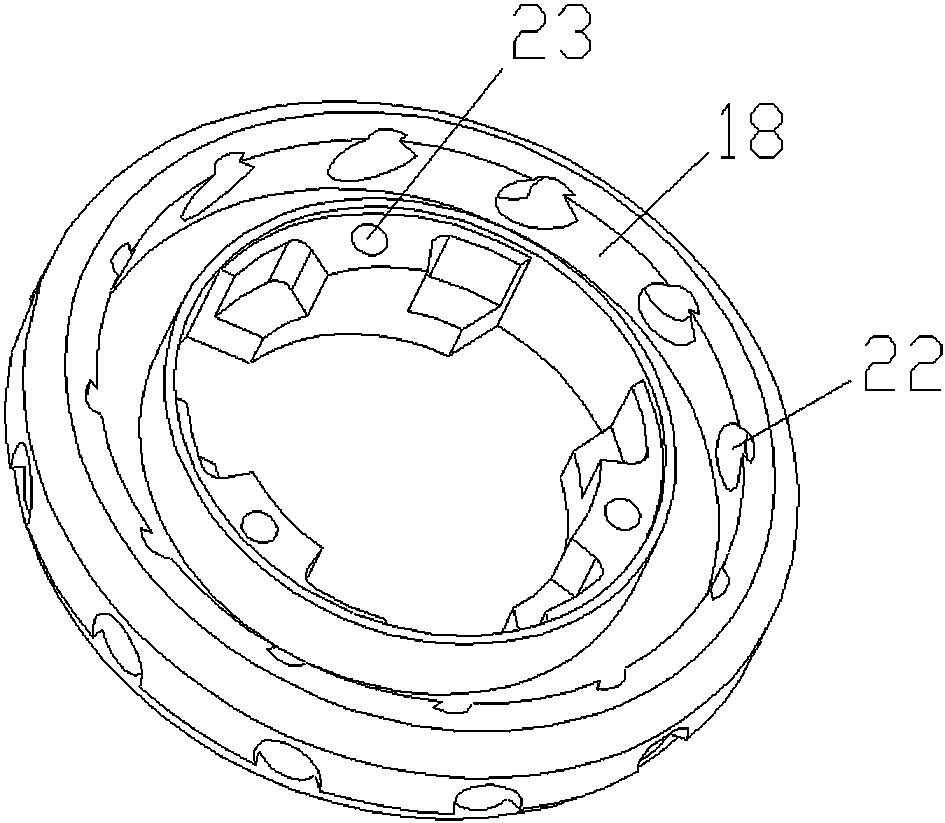

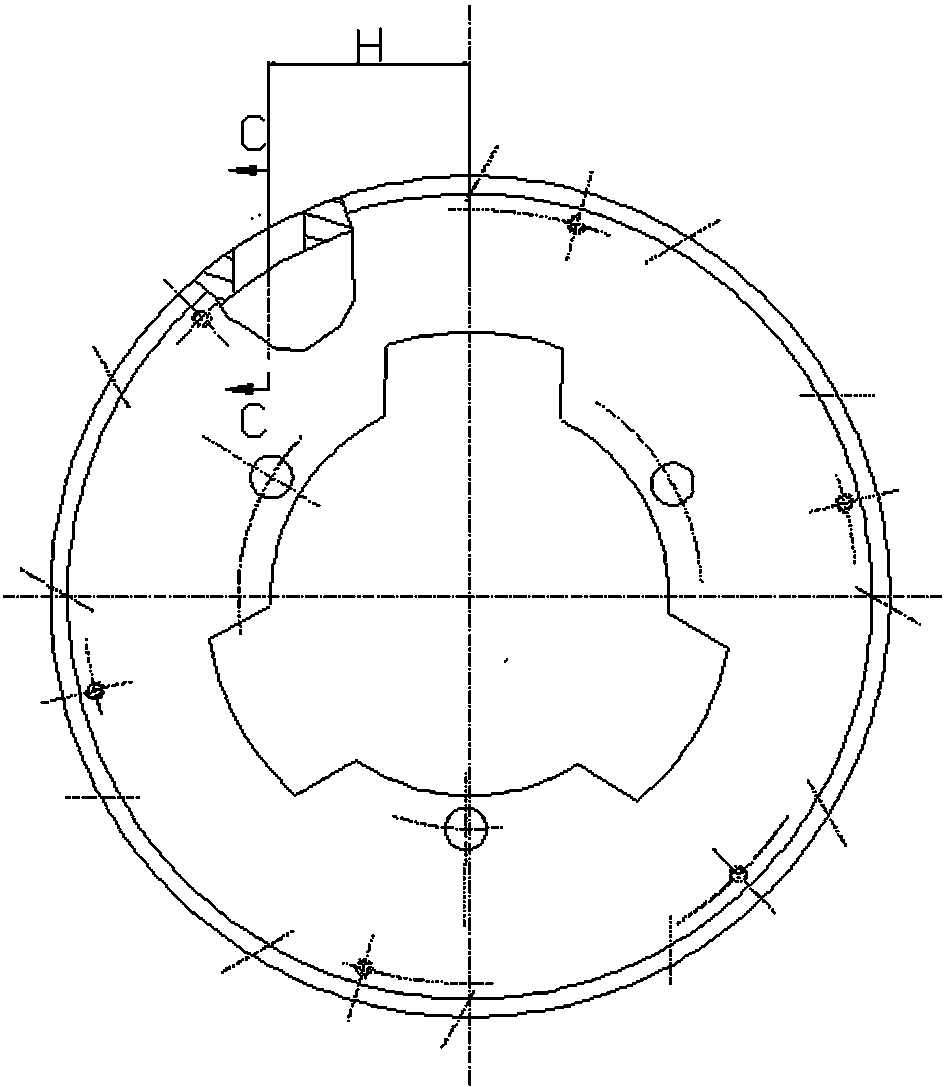

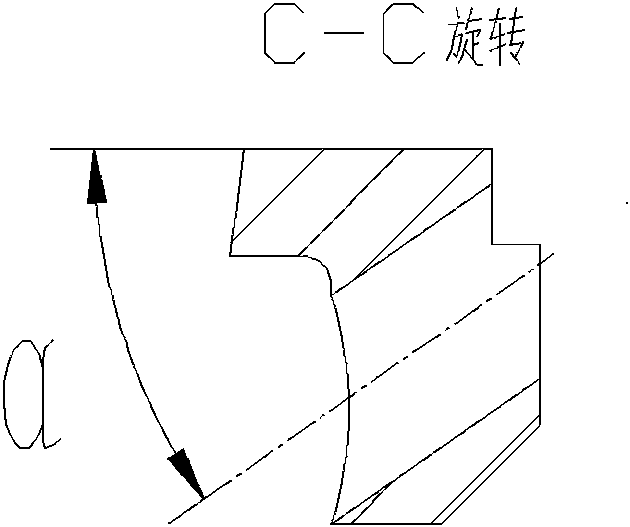

[0023] Such as Figure 1~9 As shown, a tool for punching inclined holes on an anti-reversal plate includes a base 1, and the front of the base 1 is provided with an inclined surface 17 with a set inclination, and the angle between the inclined surface and the horizontal plane is equal to the axis of the inclined hole on the anti-reverse plate. The angle between the line and the end face (ie image 3 The α angle in ) is the same, a turntable 3 is installed on the inclined surface 17 of the base 1, and a positioning plate 4 is installed in the middle of the upper side of the turntable 3 to rotate synchronously with the turntable 3 and to stick to the end face of the anti-reverse disk 18. On the positioning plate 4, there is a circular boss that cooperates with the middle hole of the anti-reverse plate 18, and the positioning pin 5 that cooperates with the through hole on the anti-reverse plate is provided on the described circular boss; A drill template 11 is arranged above the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com