Fabrication method and tooling of mesh-shaped elastic leaf spring electrical connector

An electrical connector and elastic sheet technology, which is applied in the field of mesh-shaped elastic leaf spring electrical connector fabrication and its tooling, can solve the problems of increasing the contact resistance of the electrical connector, uncontrollable installation tightness, and inability to ensure quality, etc. The effect of improving work efficiency, improving labor productivity, and reasonable tooling design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

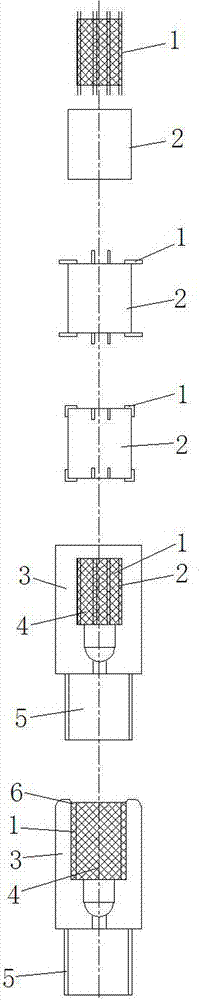

[0024] Refer to attached Figure 1~5 , the production tooling of the mesh-shaped elastic leaf spring electrical connector includes stretching (exploding) mesh-shaped elastic leaf spring tooling 7, compressing mesh-shaped elastic leaf spring tooling 8, mesh-shaped elastic leaf spring installation tooling 9 and conductive Connector closing tooling 10.

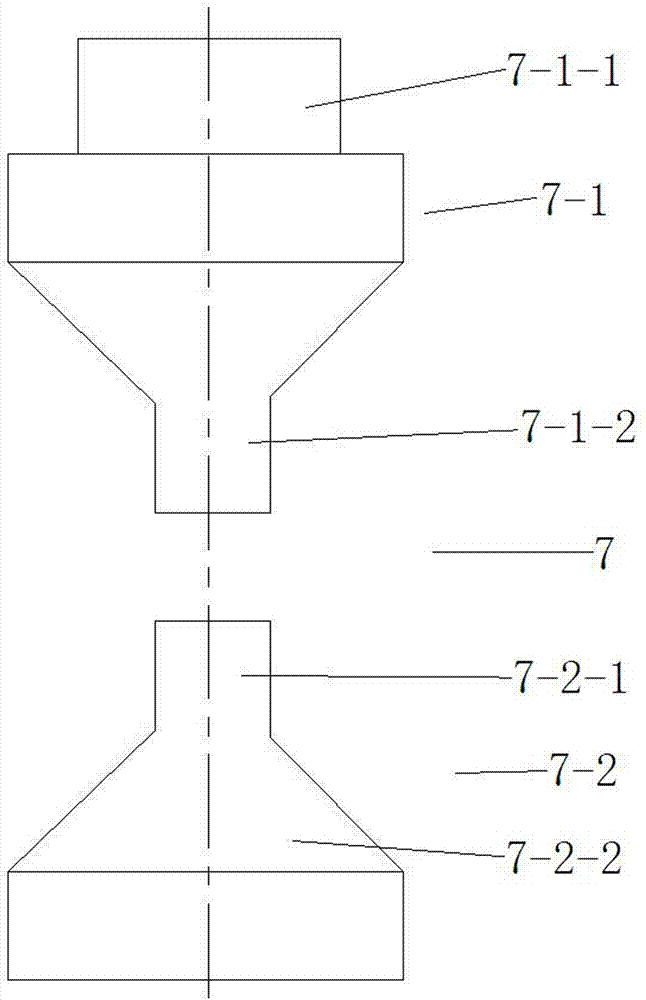

[0025] Stretching (exploding) mesh-shaped elastic leaf spring tooling 7 is composed of upper mold 7-1 and lower mold 7-2, upper mold 7-1 is provided with mold handle 7-1-1, and the lower part of mold handle is provided with cylindrical The upper mold core 7-1-2, the lower mold 7-2 are provided with a mold base, the upper part of the mold base is provided with a cylindrical lower mold core 7-2-1, and the connection between the mold base and the cylindrical lower mold core is provided with a conical step 7-2-2.

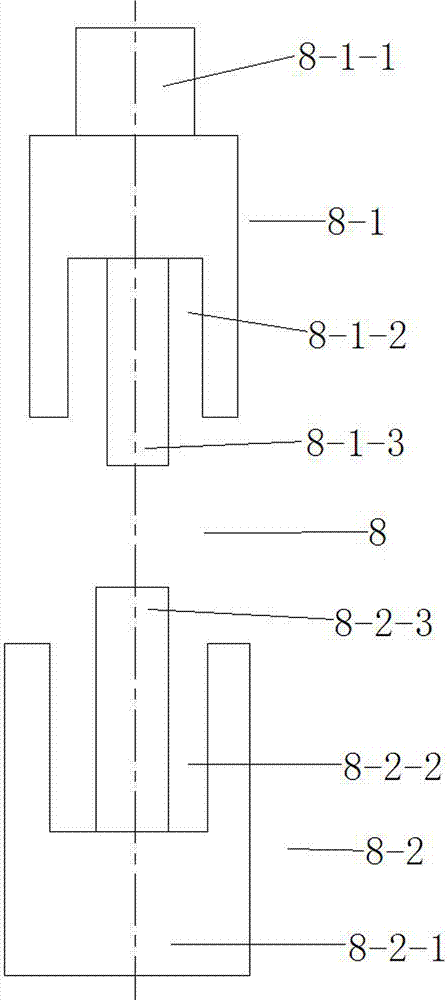

[0026] Compressing the net-shaped elastic leaf spring tooling 8 is composed of an upper die 8-1 and a lower die 8-2. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com