Linkage type step hole inner expansion mandrel clamp used for numerically controlled lathe

A CNC lathe, linkage technology, applied in the direction of expanding the mandrel, etc., can solve the problems of being unsuitable for large-scale stable production, high equipment costs and labor costs, and deformation of the outer circle and triangle in the clamping, so as to achieve various and convenient combinations. The effect of stable and reliable quality and shortened manufacturing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

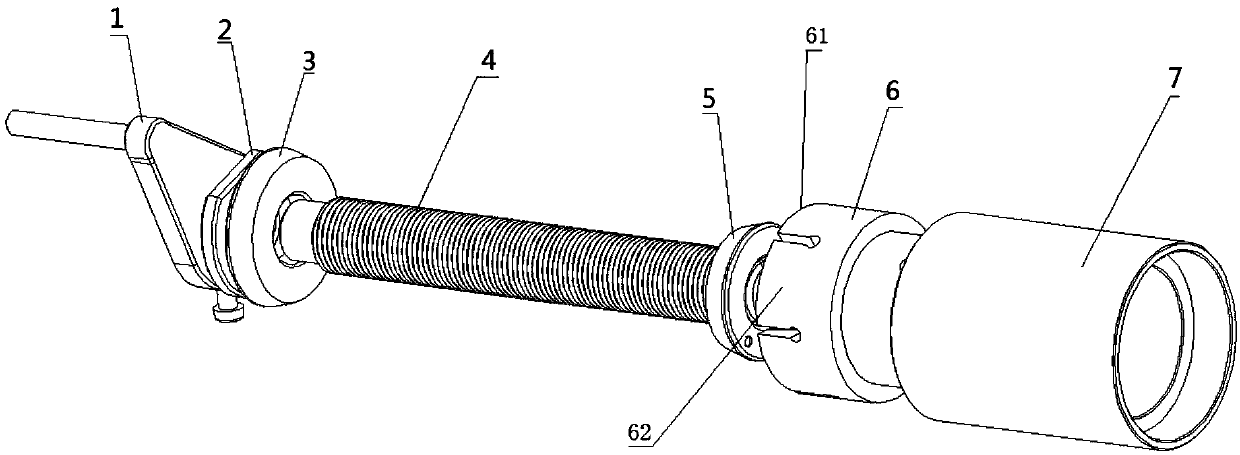

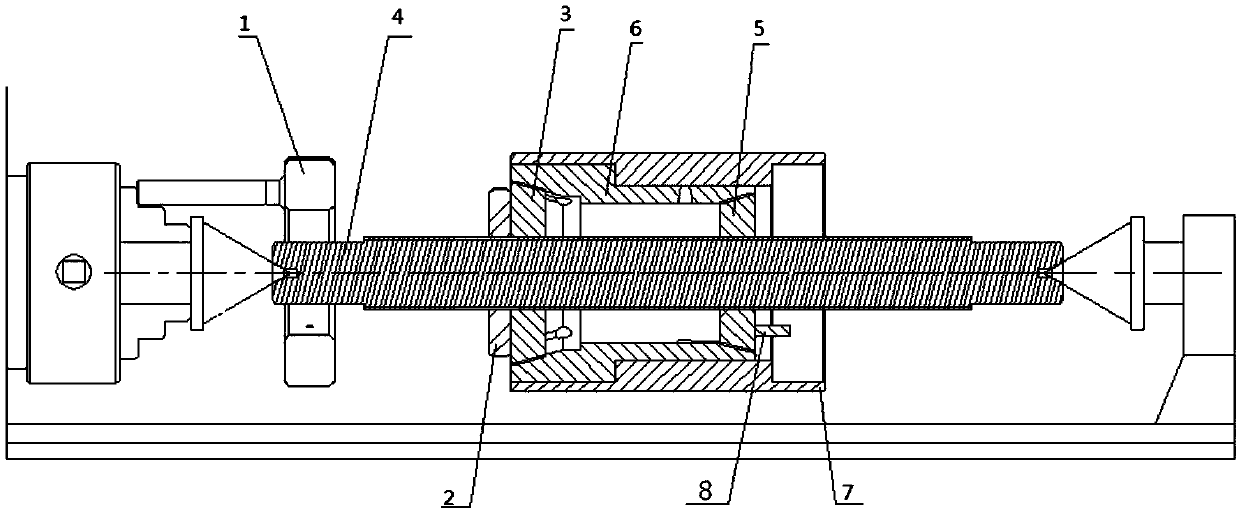

[0028] A linkage-type stepped hole internal expanding mandrel fixture for CNC lathes, its structure see figure 1 As shown, it includes a support shaft 4, two taper nuts installed on the support shaft 4 at intervals of opposite threads, and a floating expansion sleeve 6 for tightening and fixing the part 7 to be processed. Telescopic floating end 61, the inside of the floating end 61 is processed with a frustum-shaped hole matching the taper of the outer surface of the taper nut, and the two taper nuts respectively extend into the frustum-shaped holes against the two floating ends 61 The inner wall surface of the floating expansion sleeve 6 is fixedly sleeved on the support shaft 4.

[0029] see you again figure 1 As shown, the tapers of the frustum-shaped holes on the two floating ends 61 of the floating expansion sleeve 6 are the same and remain concentric.

[0030] see you again figure 1 As shown, the floating end 61 is composed of a plurality of floating pieces 62 arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com