A hollow sandwich structure molybdenum disulfide-based nanocomposite material and its preparation method

A technology of nanocomposite materials and laminated structures, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve problems such as insufficient active sites, easy aggregation of sheets, and limited improvement. Achieve the effects of improving electrochemical performance, increasing specific surface area, and improving conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The invention provides a hollow sandwich structure MoS 2 A method for preparing a base nanocomposite, the method comprising the following steps:

[0039] Step 1, prepare SiO 2 Microsphere powder, as a growth template for subsequent material preparation;

[0040] Step 2, the appropriate amount of SiO 2The microsphere powder and a certain mass of PDA are dissolved in an appropriate amount of Tris buffer solution, mixed and ultrasonically dispersed to obtain a mixed solution A;

[0041] Step 3, transfer the mixed solution A to a magnetic stirrer, add a certain amount of ammonium persulfate solution, and continue stirring for a certain period of time;

[0042] Step 4, collect the product of step 3, and carry out annealing treatment, obtain black powder sample A, set aside;

[0043] Step 5, take an appropriate amount of sample A and mix molybdate and thiourea powder in a certain amount of glucose solution, and ultrasonically stir until it is in a uniform state to obtain ...

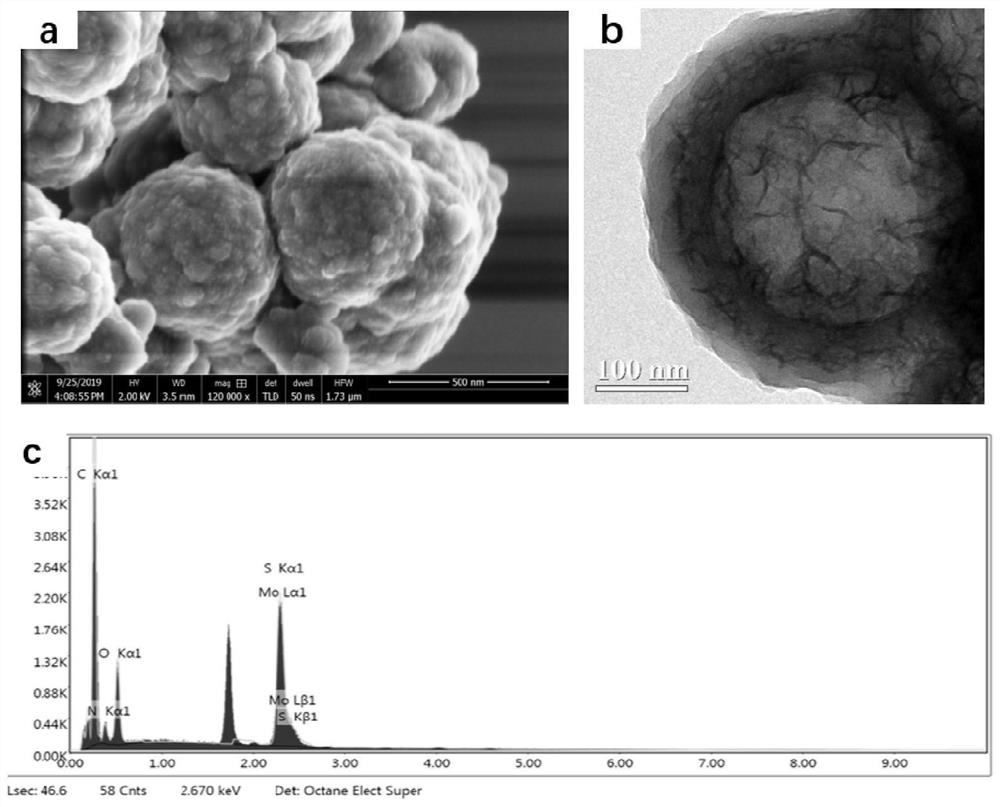

Embodiment 1

[0067] Take 1g of SiO 2 The nano-microsphere material was dissolved in 50 mL of Tris buffer solution with a concentration of 50 mmol / L and 200 mg of dopamine hydrochloride, and ultrasonicated for 25 min until the solution was uniformly dispersed. The obtained homogeneously mixed solution was transferred to a magnetic stirrer, and 10 mL of ammonium persulfate solution with a concentration of 65 mg / mL was added dropwise while stirring, and the stirring was continued for 12 h. Then it was collected by centrifugation at 8000r / min, washed four times with ultrapure aqueous solution and twice with ethanol solution, and the centrifugation time was 5 minutes each time. Finally, put the precipitate collected by washing into a vacuum oven and keep it at 60°C for vacuum drying for 10 hours. Under an argon atmosphere, it was annealed at 550°C for 3 hours. After cooling, a black powdery sample A was obtained for future use. Get 55mg sample A and 80mg (NH 4 ) 2 Mo 2 o 7 , 160mg thiourea...

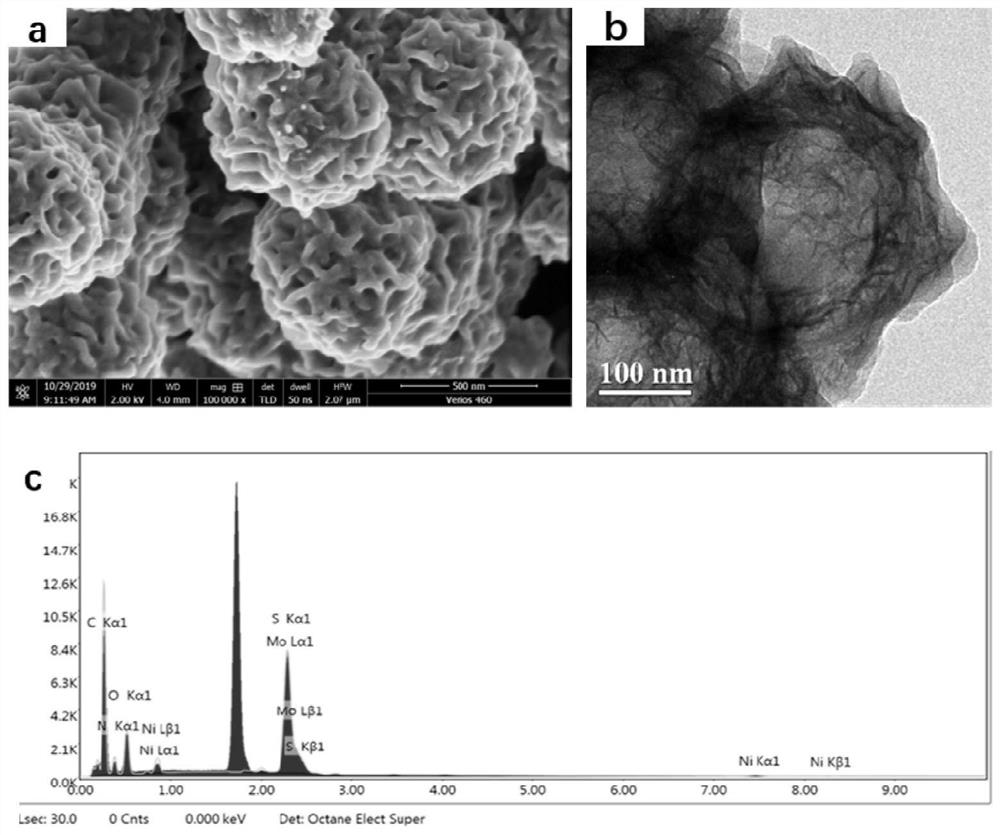

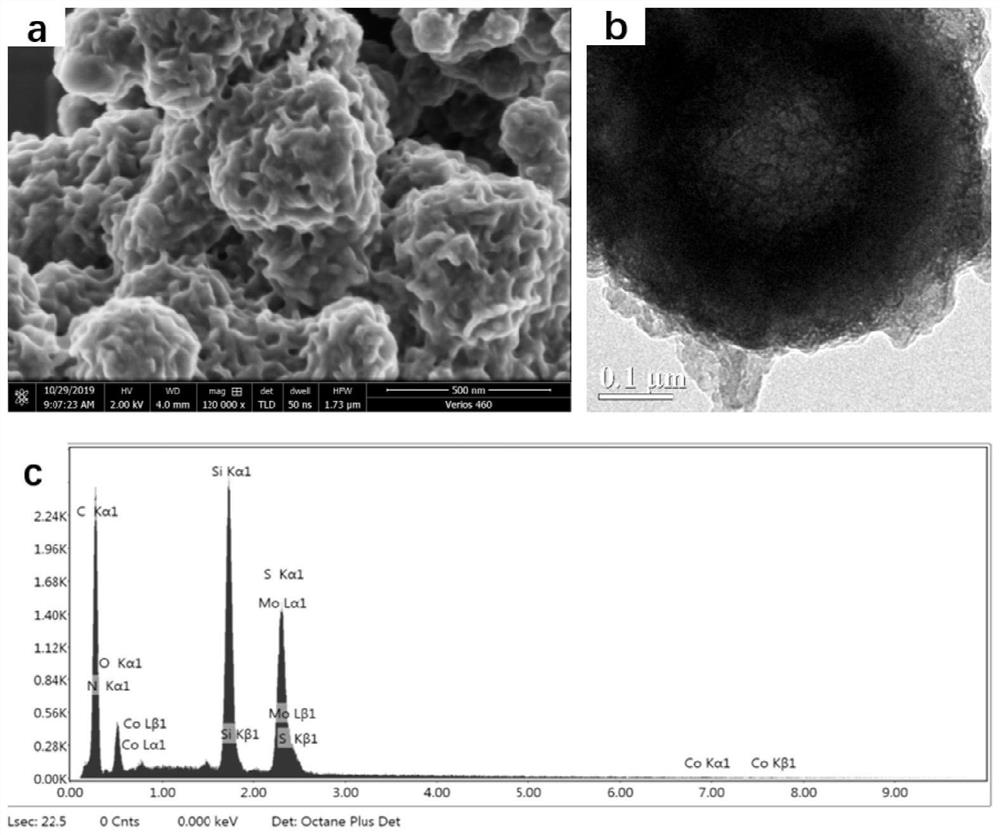

Embodiment 2

[0069] Take 1.5g of SiO 2For the nanosphere material, dissolve it and 250mg of dopamine hydrochloride in 45mL, 40mmol / L Tris buffer solution, and sonicate for 25min until the solution is uniformly dispersed. The obtained homogeneous mixed solution was transferred to a magnetic stirrer, and 18 mL of ammonium persulfate solution with a concentration of 70 mg / mL was added dropwise while stirring, and the stirring was continued for 12 h. Then it was collected by centrifugation at 8000r / min, washed four times with ultrapure aqueous solution and twice with ethanol solution, and the centrifugation time was 5 minutes each time. Finally, put the precipitate collected by washing into a vacuum oven and keep it at 60°C for vacuum drying for 10 hours. Under an argon atmosphere, it was annealed at 550°C for 3 hours. After cooling, a black powdery sample A was obtained for future use. Get 60mg sample A and 100mg (NH 4 ) 2 Mo 2 o 7 , 20mgNi(CHCOO) 2 4H 2 0, 200mg thiourea, it is dissol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com