Dampness removing and fresh air integrated machine system for breeding sheds in cold region

An all-in-one machine and breeding house technology, applied in animal houses, applications, animal husbandry, etc., can solve problems that affect the health and quality of farmed animals, expensive prices, and high humidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

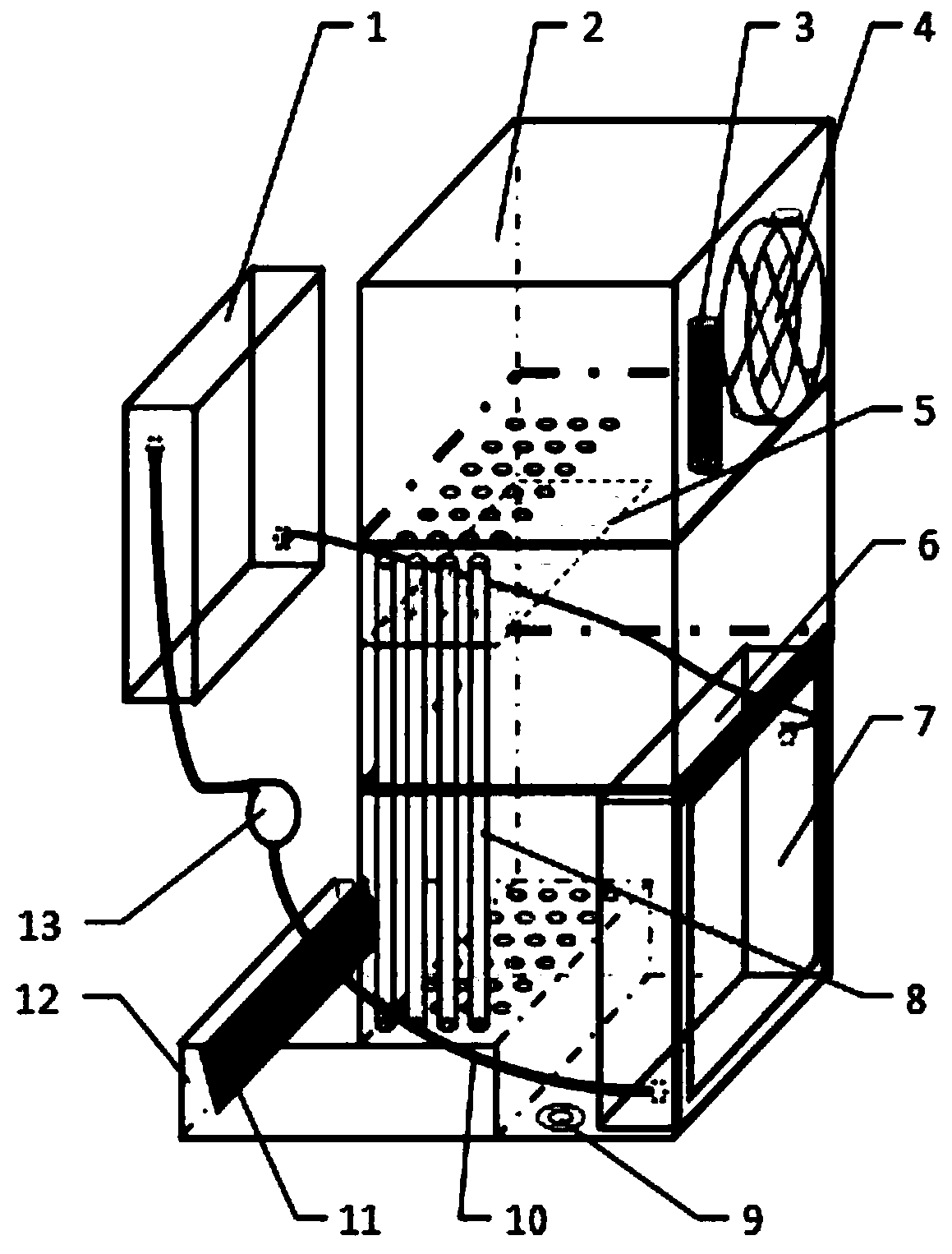

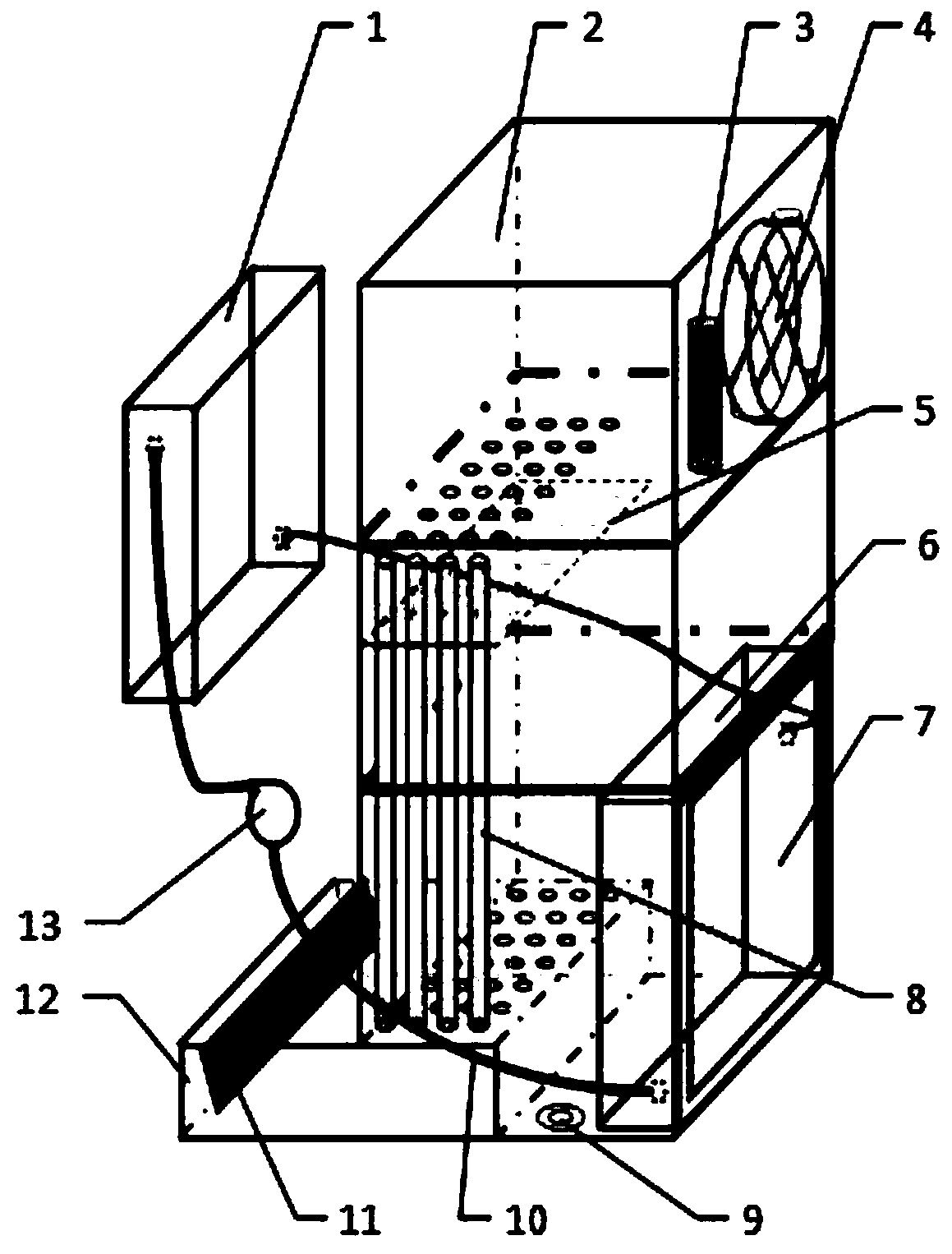

[0018] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. The dehumidification and fresh air integrated machine system for breeding houses in cold areas consists of outdoor self-cooling box 1, integrated machine shell 2, thermal compensation device 3, air intake fan 4, surface cooling and dehumidification device 6, fresh air exhaust pipe 8, connecting hose 10, automatic air volume The adjusting plate 11 and the circulation pump 13 are assembled; the upper end of the all-in-one machine housing 2 has an air outlet airtightly connected with the air inlet fan 4, and the air intake fan 4 is installed on the outside of the air outlet at the upper end of the all-in-one machine shell 2, and the all-in-one machine shell 2 There is an air inlet for dehumidification inside the house that is airtightly connected to the surface cooling and dehumidifying device 6 on one side of the lower end. The side is provided with an out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com