A plate pure shear experimental loading device

A loading device and pure shearing technology, applied in measuring devices, using stable shear force to test material strength, analyzing materials, etc., can solve the problem of affecting the pure shear stress value, the degree of influence cannot be quantitatively described, and cannot be guaranteed. Pure shear stress state and other problems, to achieve the effect of simple implementation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

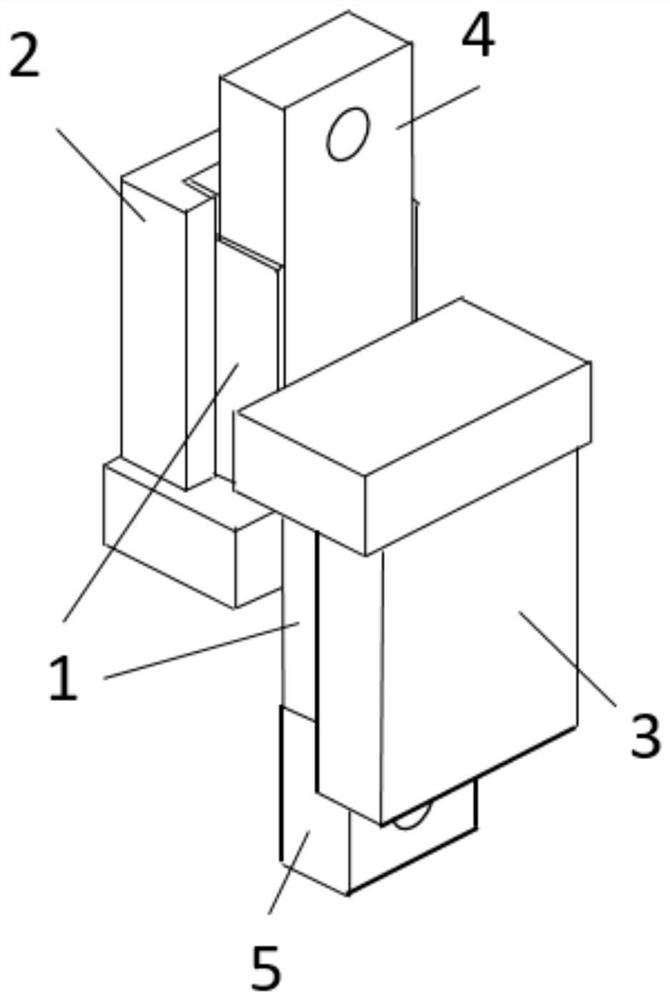

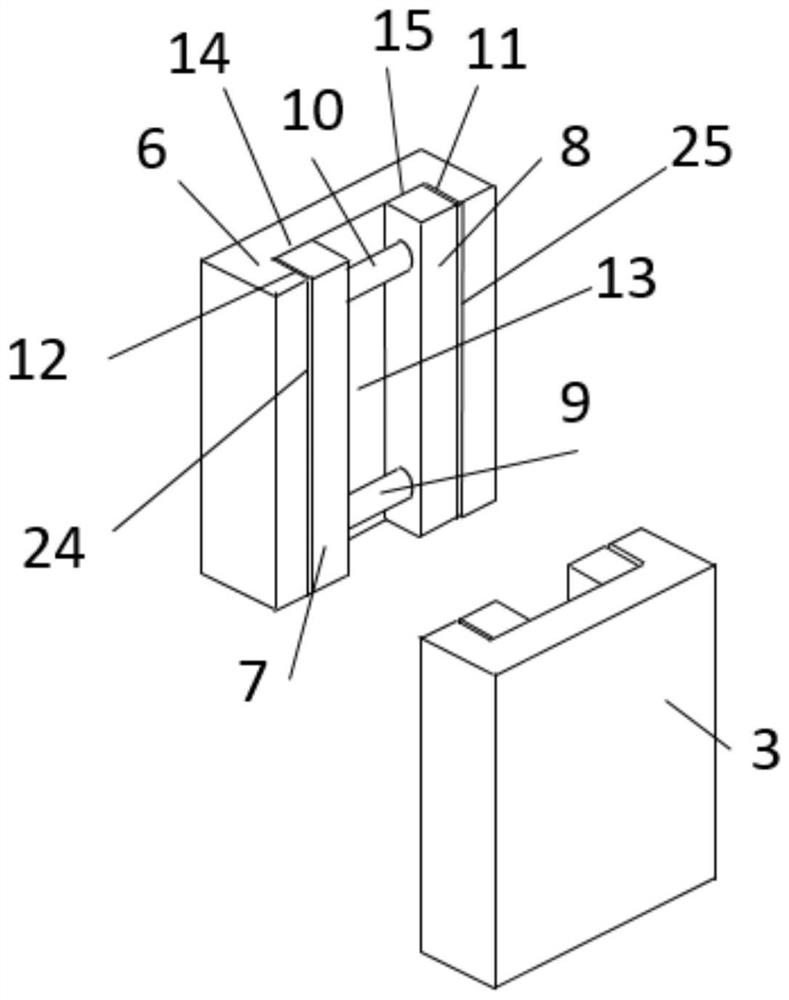

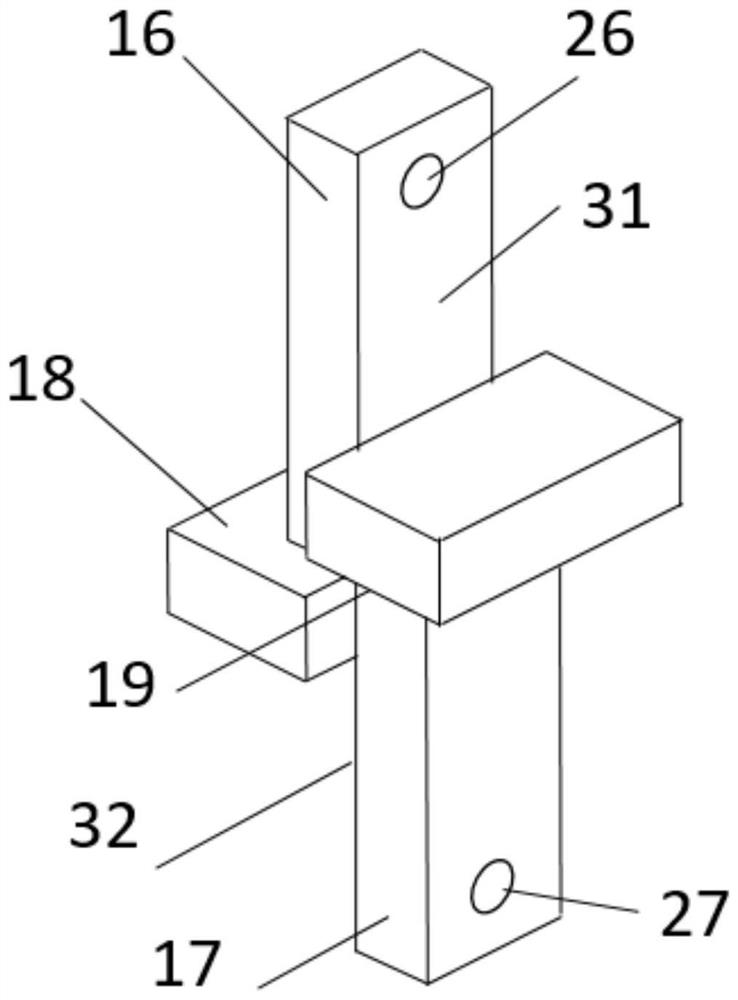

[0028] see Figure 1-4, this embodiment provides a loading device for plate pure shear experiments, including a first connection assembly 2 and a second connection assembly 3, the first connection assembly 2 and the second connection assembly 3 have the same structure and are relatively misplaced. The first connecting component 2 and the second connecting component 3 are equipped with a first moving bar 7 and a second moving bar 8 opposite to each other. The first connecting component 2 and the second connecting component 3 are equipped with a plate 1 to be tested. The first moving bar 7 and the second moving bar 8 are connected through the first locking bolt system 10 and the second locking bolt system 9, and the inside of the first connecting assembly 2 is provided with a U-shaped structure Locate the inner surface 13, the left locking surface 24 of the first moving bar and the right locking surface 25 of the second moving bar, the positioning of the plate end positioning su...

Embodiment 2

[0037] On the basis of Example 1, for the connection of the plate 1 to be tested with the first connection assembly 2 and the second connection assembly 3, first, a pair of plate 1 to be tested is placed between the first connection assembly 2 and the second connection assembly 3 In the opening, since the first connecting component 2 and the second connecting component 3 operate in the same manner, here only the fixing process of the first connecting component 2 and the panel 1 to be tested is described as an example.

[0038] The plate 1 to be tested is placed in the first connection assembly 2, so that its positioning surface 22 is close to the positioning inner surface 13 of the first connection assembly 2, and then the first moving bar 7 and the second moving bar 8 are adjusted so that The right inner surface 11 of the first connection assembly, the left inner surface 12 of the first connection assembly is close to the inner surface 20 of the upper half of the plate 1 to be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com