Boiler scale removing device

A technology for removing device and boiler scale, applied in boiler cleaning devices, lighting and heating equipment, fluid heaters, etc., can solve the problems of low removal efficiency, insufficient removal, and laborious cleaning, so as to achieve good removal effect and improve cleaning efficiency. and cleanliness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

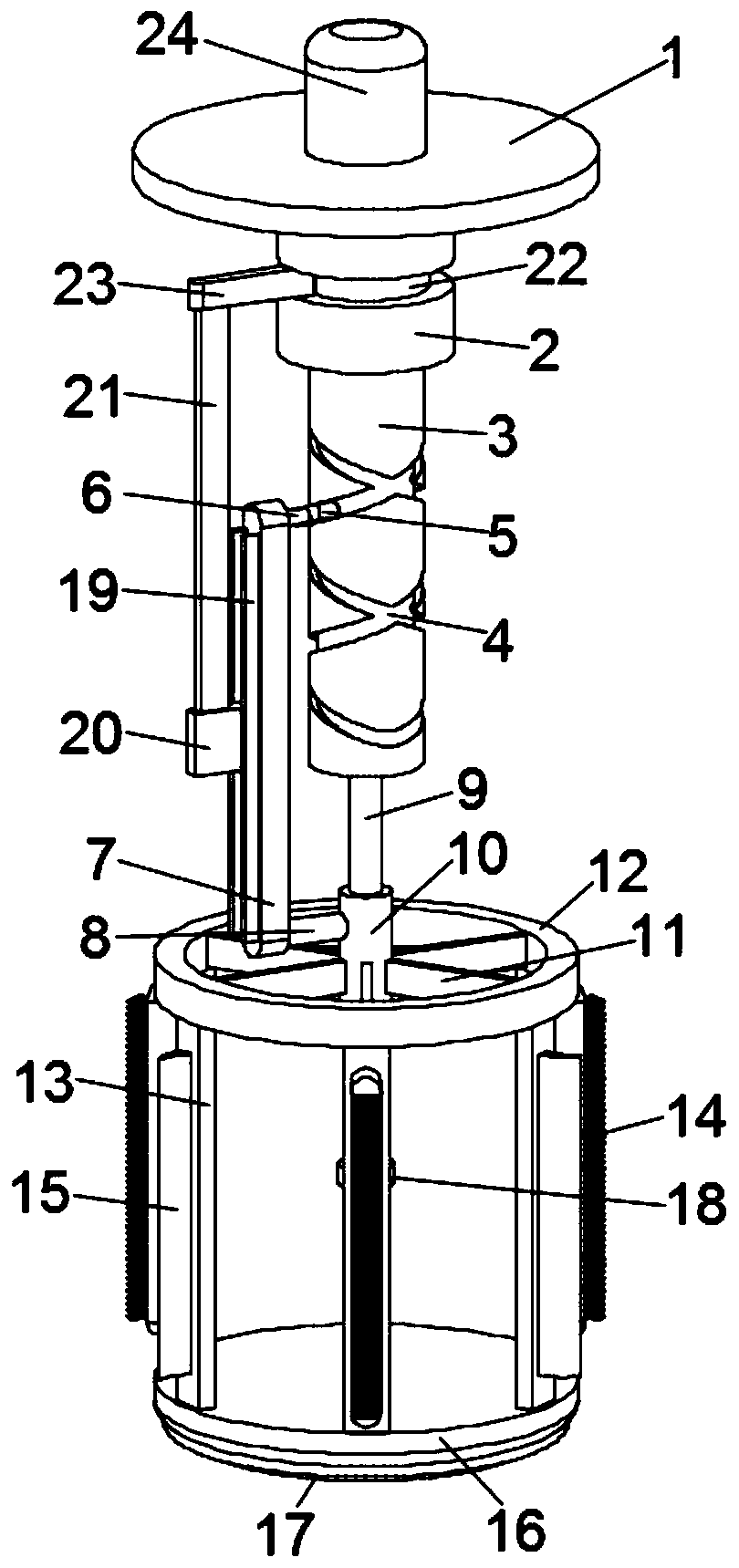

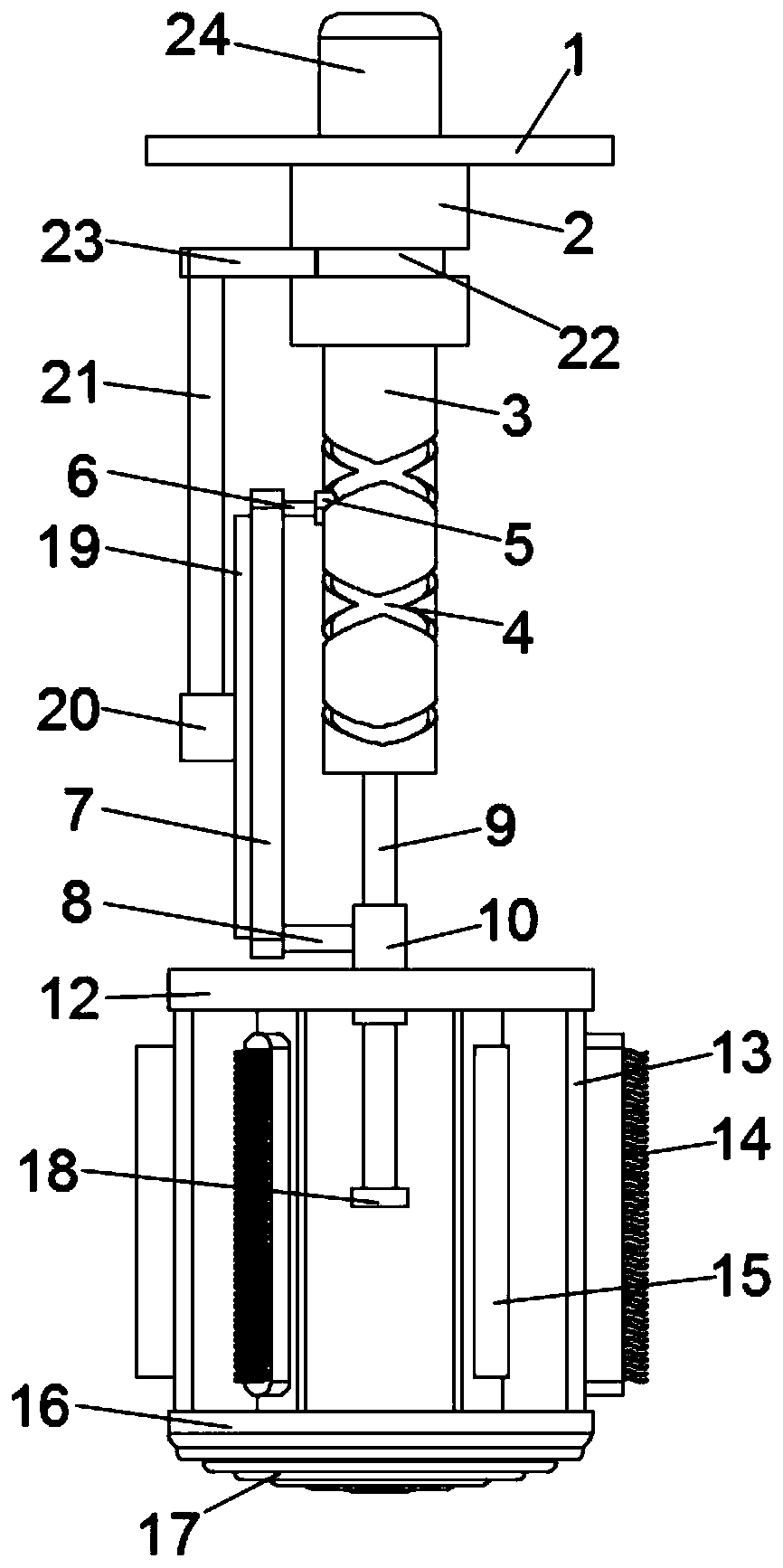

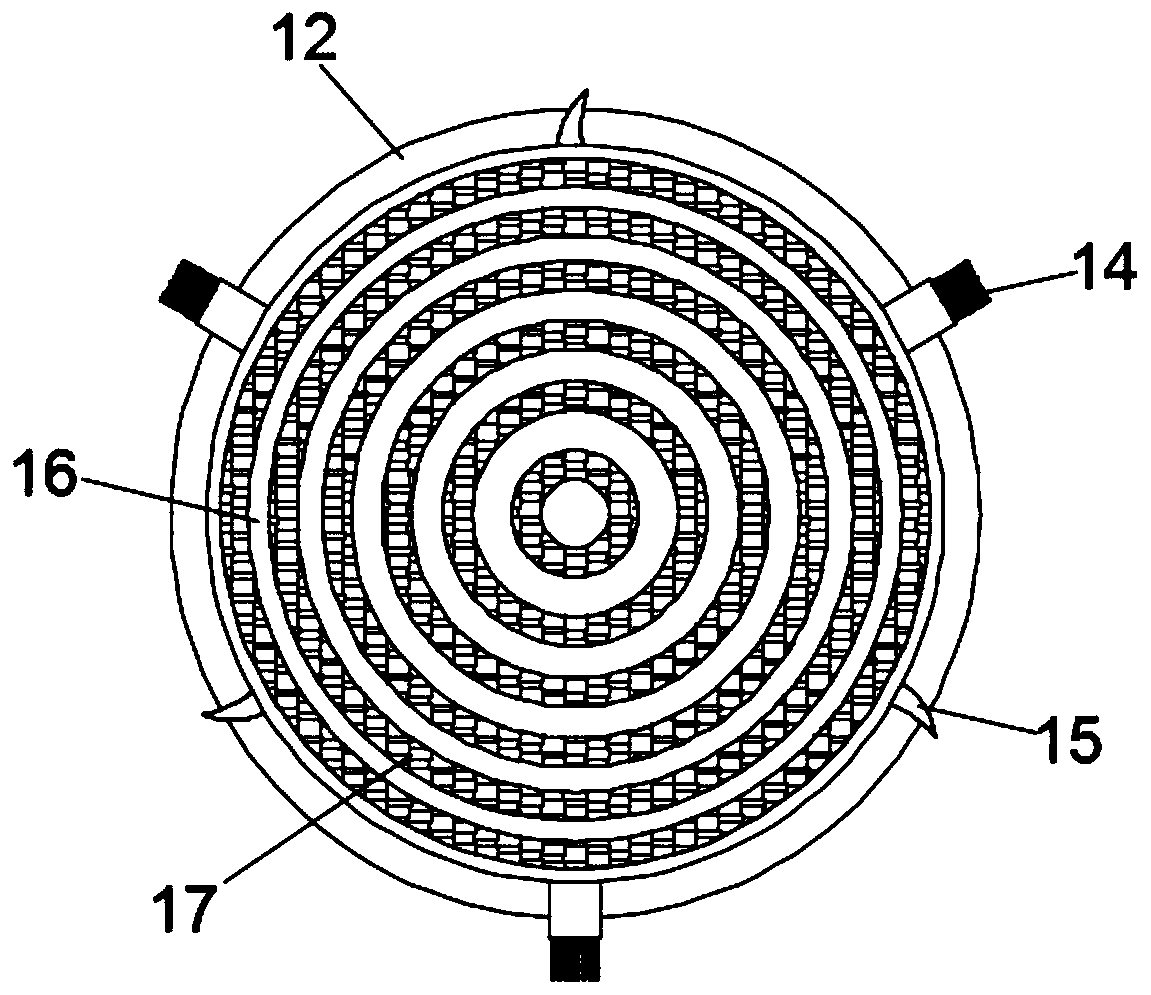

[0023] see figure 1 , a boiler scale removal device, comprising a mounting plate 1 and a base 2, the base 2 is fixed on the lower end surface of the mounting plate 1, a reciprocating screw rod 3 is fixed on the bottom of the base 2, and a reciprocating screw rod 3 is provided on the reciprocating screw rod 3 Groove 4, crescent pin 5 is movably embedded in the reciprocating groove 4, a fixed rod 9 is vertically installed at the bottom of the reciprocating screw rod 4, and a sliding sleeve 10 is provided on the movable sleeve of the fixed rod 9, and the sliding sleeve 10 and the crescent pin 5 are connected with a transmission assembly, and there are several support plates 11 evenly distributed in the circumferential direction under the sliding sleeve 10, and a turret 12 is fixed on the periphery of the support plate 11, and a number of Fixed plate 13, cleaning brush 14 and scraper 15 are installed alternately on the adjacent fixed plate 13, chassis 16 is installed on the bottom...

Embodiment 2

[0033] A boiler scale removal device, comprising a mounting plate 1 and a base 2, the base 2 is fixed on the lower end surface of the mounting plate 1, a reciprocating screw rod 3 is fixed on the bottom of the base 2, and a reciprocating groove is opened on the reciprocating screw rod 3 4. A crescent pin 5 is movably embedded in the reciprocating groove 4, a fixed rod 9 is installed vertically on the bottom of the reciprocating screw rod 4, and a sliding sleeve 10 is provided on the movable sleeve of the fixed rod 9, and the sliding sleeve 10 There is a transmission assembly connected between the crescent pin 5, a number of supporting plates 11 are evenly distributed in the circumferential direction under the sliding sleeve 10, a turret 12 is fixed on the periphery of the supporting plate 11, and a number of fixing plates are evenly distributed on the lower end surface of the turret 12. plate 13, cleaning brushes 14 and scrapers 15 are installed alternately on the adjacent fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com