Glass fiber impregnating agent, sound-absorbing glass fiber and filling process thereof

A glass fiber and sizing technology, which is used in mufflers, engine components, machines/engines, etc., can solve the problem of unsatisfactory quantity and content, and achieve the effect of reducing automobile noise, ensuring dispersion and reducing emissions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

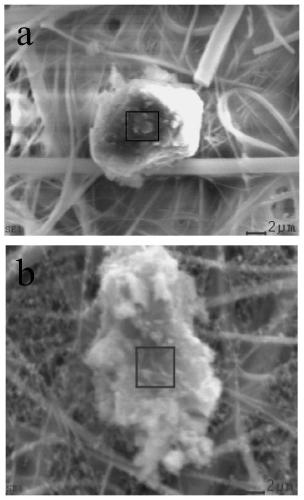

Image

Examples

Embodiment 1

[0029] Prepare 4 different glass fiber sizing agents I to IV according to the different formula combinations in Table 1. The preparation method is as follows: first, add water and a pH regulator to the coupling agent to completely hydrolyze the coupling agent; Add lubricant, antistatic agent and film-forming agent, and stir evenly; finally add remaining water, stir evenly to obtain the glass fiber sizing agent.

[0030] Table 1 The formulation combinations of different glass fiber sizing agents

[0031]

[0032]

Embodiment 2

[0034] Preparation of sound-absorbing fiberglass:

[0035] The glass fiber sizing agents I-IV prepared in Example 1 were coated on the glass fiber matrix at a mass percentage of 0.5% to form sound-absorbing glass fibers 1#-4#.

Embodiment 3

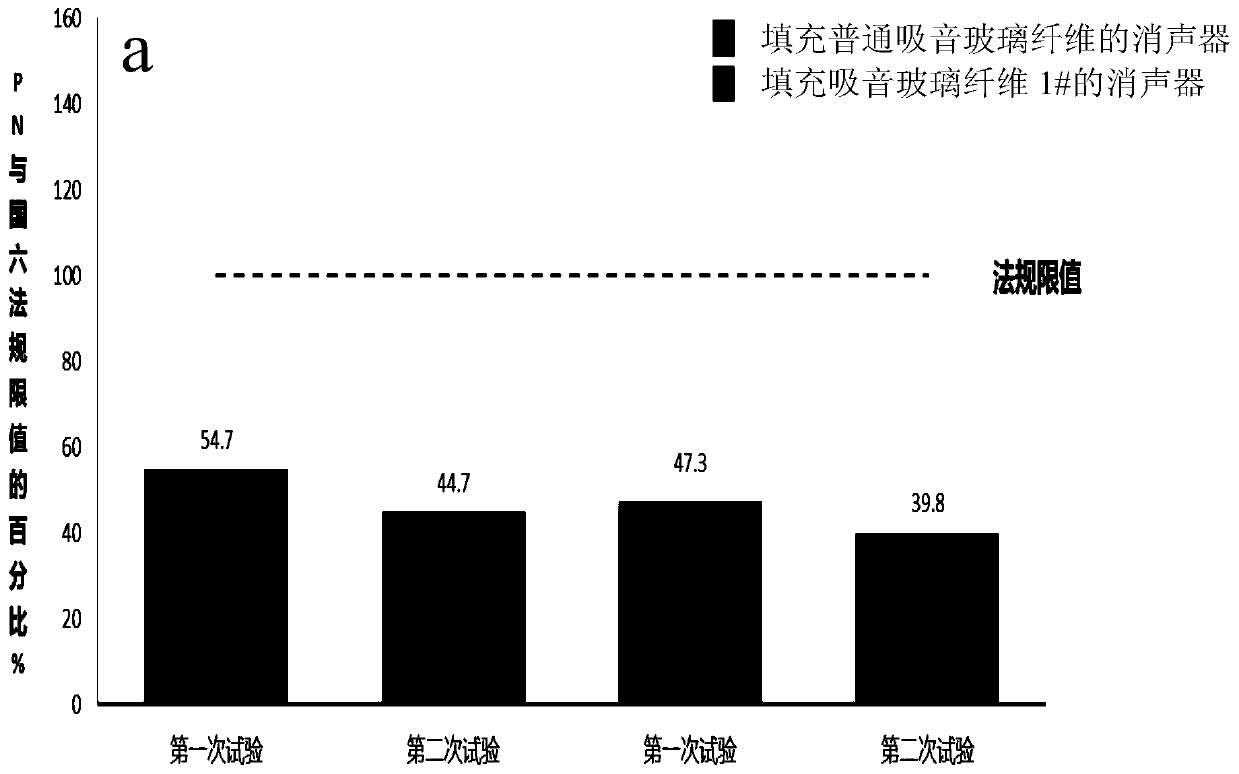

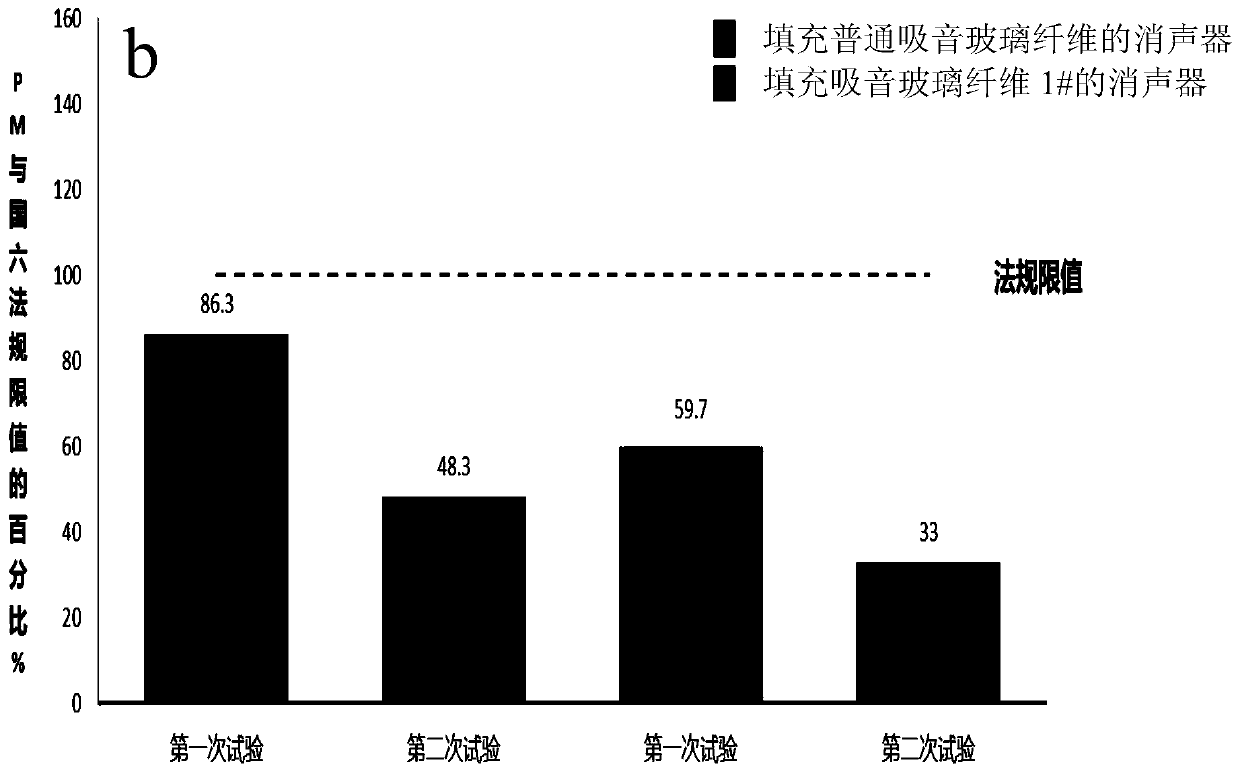

[0037] Fill the 4 kinds of sound-absorbing glass fibers 1#~4# prepared in Example 2 into the muffler cylinder to form 4 different tail gas treatment products I~IV, wherein the filling process is: the puffing pressure is set to 200KPa, and the puffing speed is 6000mm / s, working temperature 10℃, keep relative humidity ≤60%.

[0038] At the same time, the ordinary glass fiber was filled into the muffler cylinder according to the ordinary filling method to form the exhaust gas treatment product V, which was used as the control group.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com