Continuous feeding system for automobile trim electroplating and feeding device thereof

A technology for automotive trim parts and feeding devices, which is applied in the direction of electrolysis process, electrolysis components, cells, etc., can solve the problems of limited application range, adjustment position of conveying device, transportation of plating trim parts in difficult electroplating pools, etc., and achieves wide application range , good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

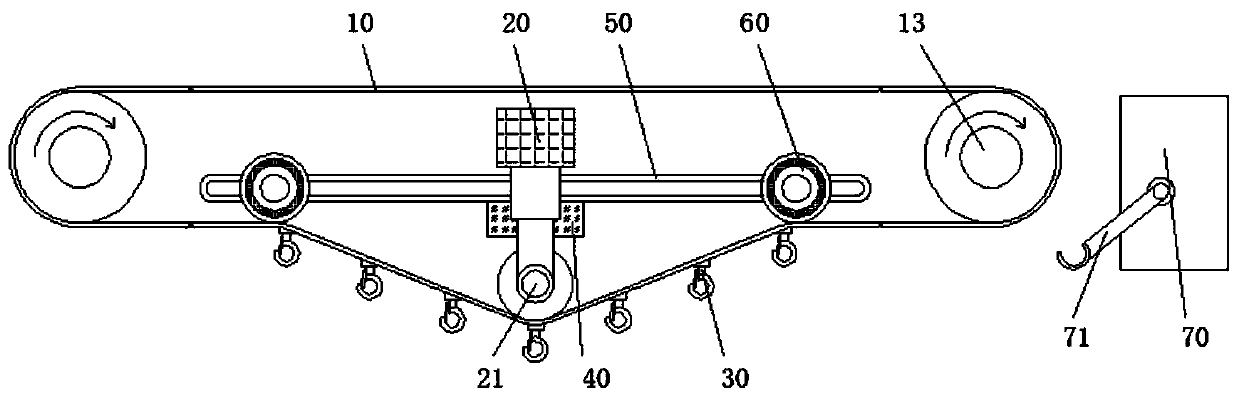

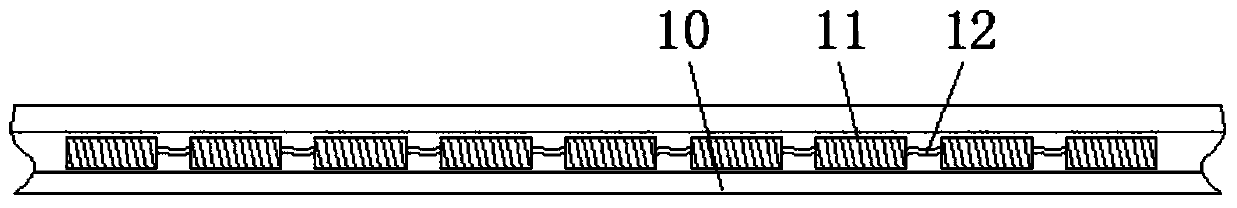

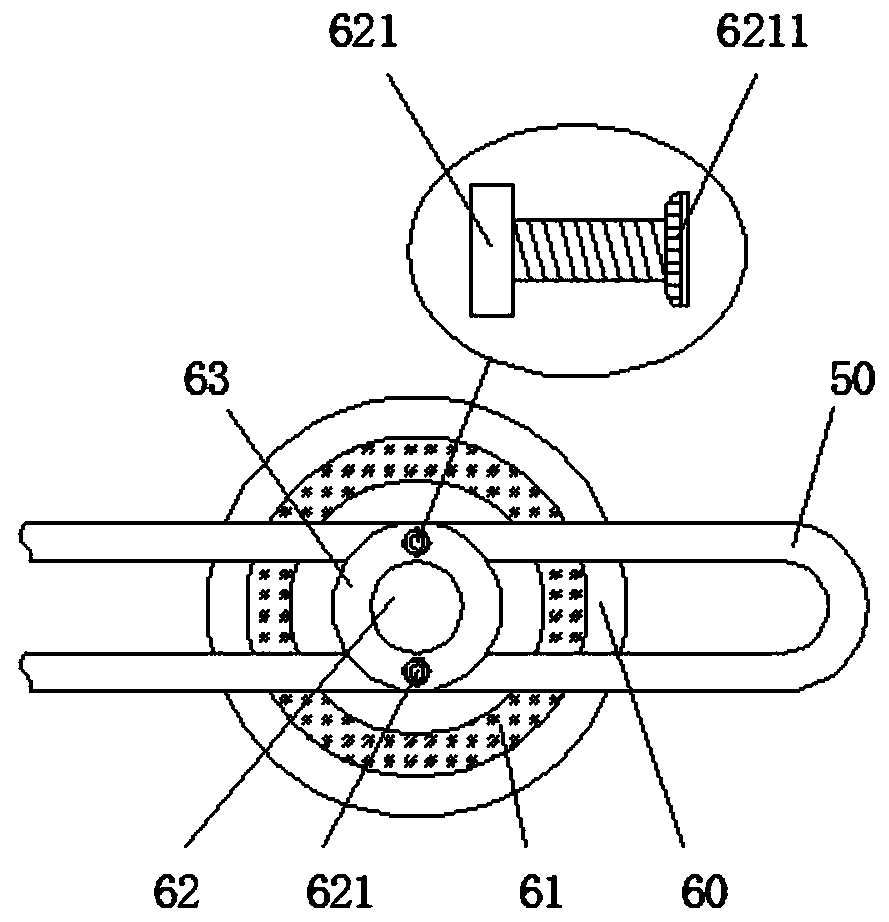

[0026] Such as figure 1 As shown, a continuous feeding device for automotive trim electroplating described in this embodiment includes a transmission belt 10, a hydraulic rod 20, a suspension mechanism 30, a sliding suspension 50, a suction limit wheel 60 and a motor 70, and the transmission belt The middle position of both sides of the 10 is provided with a rotating wheel 13, the rotating wheel 13 on one side is provided with a motor to control its rotation, the middle position of the transmission belt 10 is provided with a hydraulic rod 20, and the output shaft of the hydraulic rod 20 The bottom is rotatably connected to the limit wheel 21, the limit wheel 21 is in contact with the upper edge of the transmission belt 10, the middle position of the transmission belt 10 is fixed with a sliding suspension 50, and the sliding suspension 50 is located on both sides of the hydraulic rod 20 and is slidingly connected with The suction limiting wheel 60 is used to absorb the transmis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com