Intelligent warehousing system for prebaked anode carbon blocks

A technology of intelligent storage and prebaked anodes, which is applied in the direction of conveyors, storage devices, transportation and packaging, etc., can solve the problem that the height of the workshop is not effectively utilized, the stacking height of prebaked anode carbon block storage is limited, and multi-specification carbon blocks Difficult stacking and other issues, to avoid the different lengths of storage, avoid the risk of collapse, and improve product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

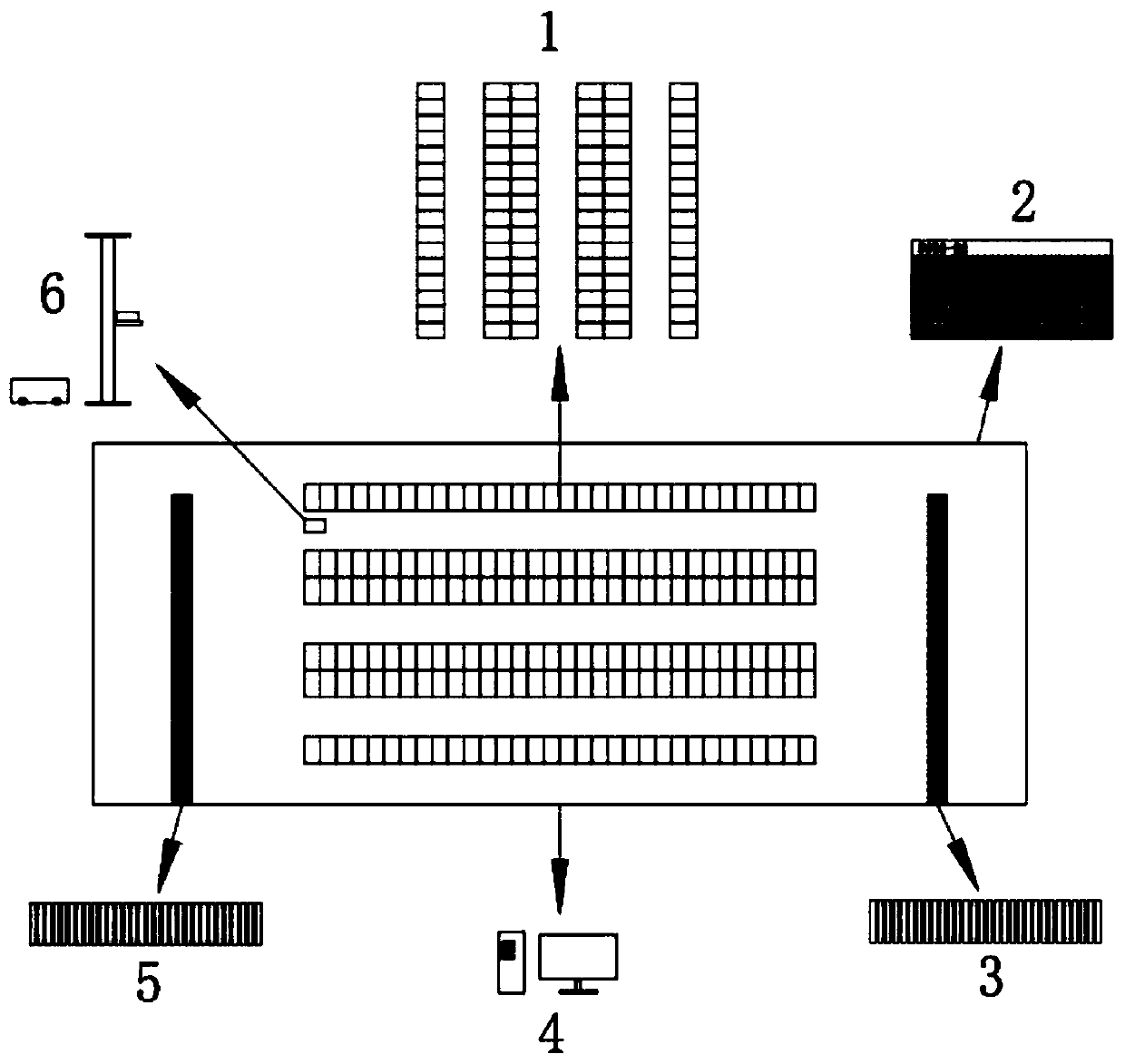

[0012] Such as figure 1 As shown, the present invention is implemented in this way: the prebaked anode carbon block intelligent storage system of the present invention is transported to the prebaked anode carbon block intelligent storage warehouse by the chain plate conveyor from the prebaked anode block from the anode roasting workshop. After the identification code is completed on the chain conveyor 5, the intelligent dispatching control system 4 dispatches the conveying and lifting system 6 to send the carbon block to the designated storage position of the carbon block storage rack 1 for storage. When the carbon block needs to be out of the warehouse, the intelligent dispatching control system 4 dispatches The conveying and lifting system 6 takes out the designated carbon b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com