Thermally insulated synthetic resin container, thermally insulated synthetic resin lid and manufacturing method therefor

A synthetic resin and container technology, applied in the fields of heat-insulating synthetic resin containers and heat-insulating synthetic resin covers, can solve problems such as increased manufacturing costs, and achieve the effects of simplified manufacturing, reduced manufacturing costs, and high effective volume ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

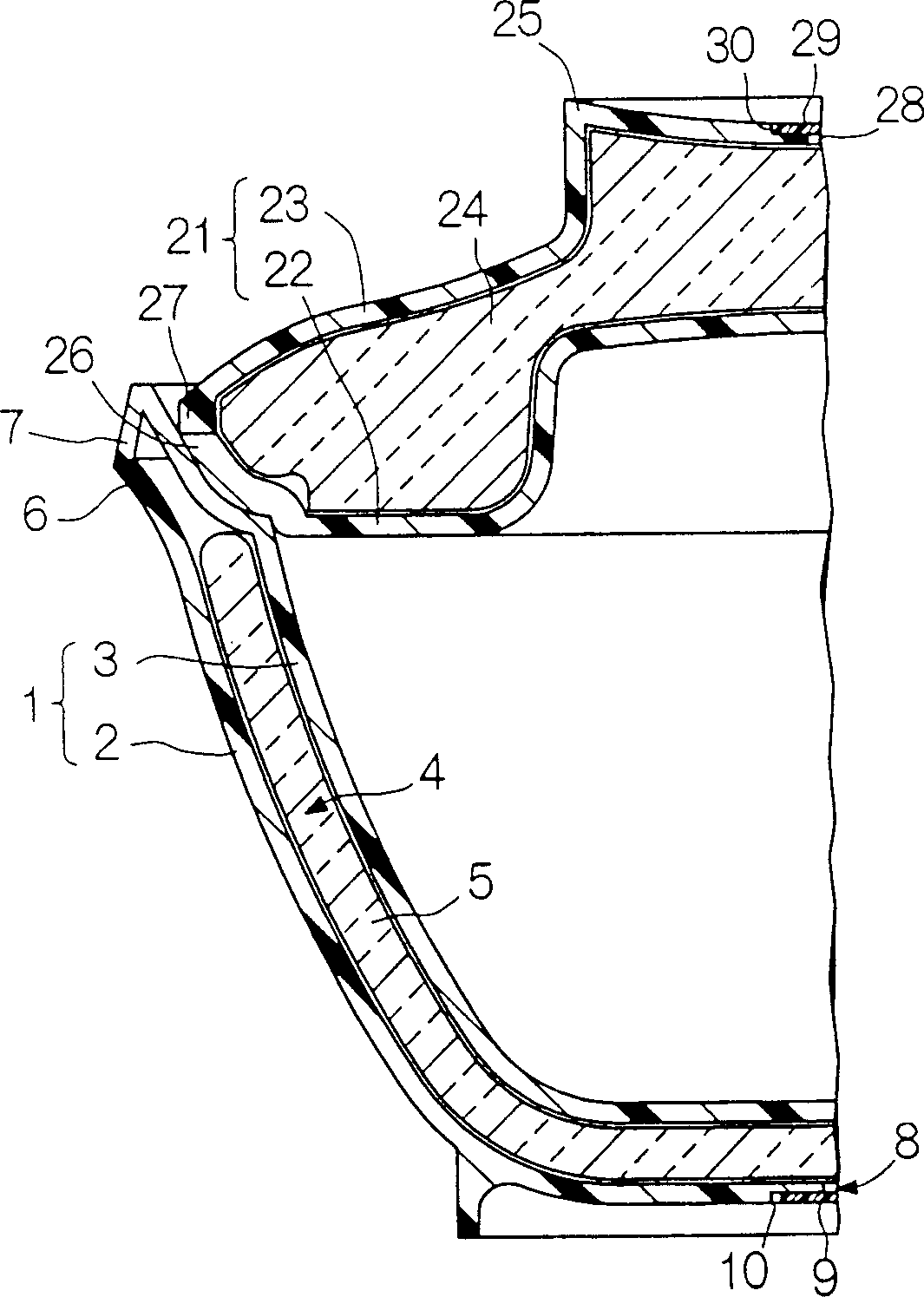

[0037] figure 1 A first embodiment of a heat-insulating synthetic resin container (hereinafter referred to as a heat-insulating container) and a heat-insulating synthetic resin cover (hereinafter, a heat-insulating cover) according to the present invention, which is a partition The hot tableware includes a heat-insulating container 1 and a heat-insulating cover 21 covering the upper opening of the heat-insulating container 1 .

[0038] The insulated container 1 is formed as a double-walled bowl, which includes an outer container 2 and an inner container 3 . The diameter of the inner surface of the outer container 2 is larger than the diameter of the outer surface of the inner container 3 , and a heat insulating material 5 is filled in the space between the outer container 2 and the inner container 3 to form a heat insulating layer 4 . The outer container 2 and the inner container 3 are made of a synthetic resin having chemical resistance and gas barrier properties by injectio...

example 1

[0087] manufacture figure 1 Insulated container 1 shown. The outer container 2 and the inner container 3 having a thickness of 2 mm were injection-molded with polyethylene terephthalate (manufactured by Sanleng Chemical Co., Ltd.). At this time, the width of the space between the outer and inner containers 2 and 3 was 5 mm. Further, on the outer surface of the inner container 3 and the inner surface of the outer container 2, such as Figure 5 The radially shallow grooves 11 are shown, thereby minimizing flow resistance when evacuated and filled with a low thermal conductivity gas.

[0088] Polyethylene is used as insulating material 5 . It was moulded to a thickness of 5mm and had a connected lattice structure.

[0089] The heat insulating material 5 is provided between the outer container 2 and the inner container 3, and the outer container edge portion 6 and the inner container edge portion 7 are connected integrally by a vibration welding machine.

[0090] After that, ...

example 2

[0094] as figure 1 In another aspect of the illustrated insulated container 1, an outer container 2 and an inner container 3 are molded using multi-colored plastics to make an insulated container in which the inner and outer layers are made of different types of synthetic resins.

[0095] The outer container 2 and the inner container 3 were made by integral two-color molding, and the atmospheric side of the outer container 2 was a 1.5 mm thick cyclopolyolefin (trade name: APEL, manufactured by Mitsui Chemical Co., Ltd.), and the heat insulating layer side was 1.5mm thick polyketone (manufactured by Shell Japan Ltd.). At this time, the thickness of the space between the outer container 2 and the inner container 3 was 5 mm. Also, on the outer surface of the inner container 3 and the inner surface of the outer container 2, such as Figure 5 The radially shallow grooves 11 are shown to minimize flow resistance when evacuating and filling with a low thermal conductivity gas.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com