Garbage transfer station

A garbage transfer station and garbage technology, which is applied in garbage collection, garbage transfer, loading/unloading, etc., can solve the problems of small amount of extruded garbage material, easy leakage of garbage material, easy to emit odor, etc., so as to prevent odor. The effect of dispersing and improving the effective volume ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

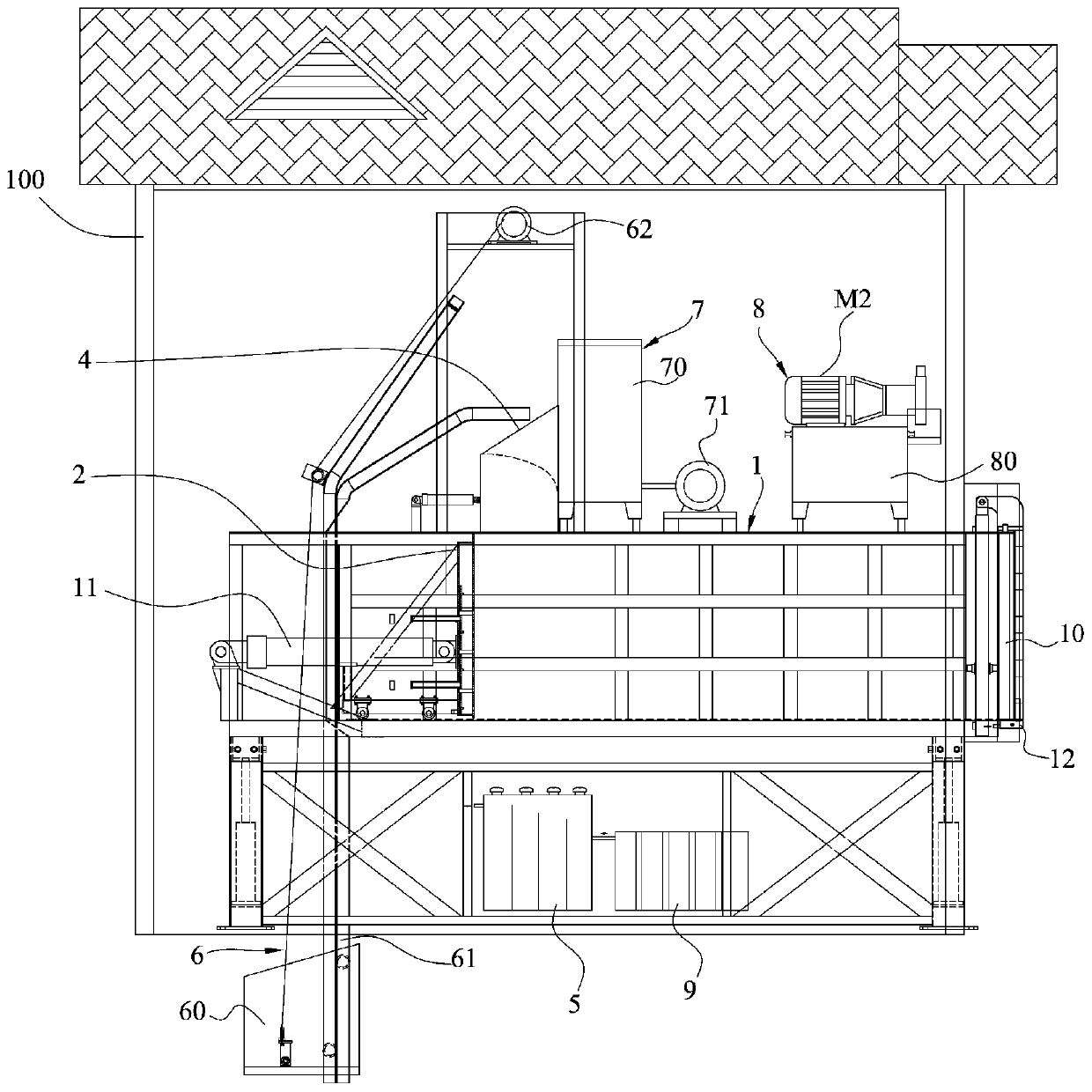

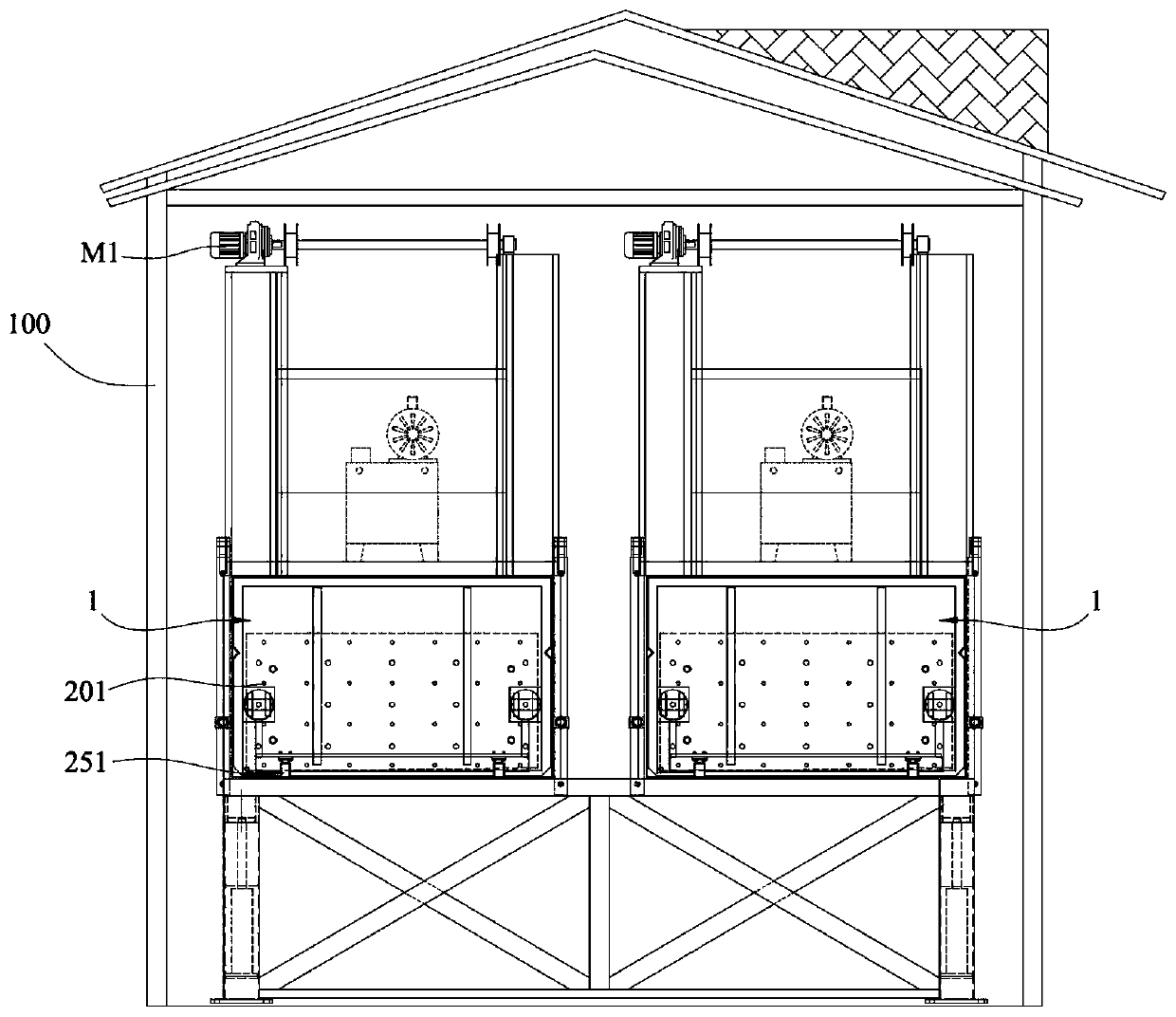

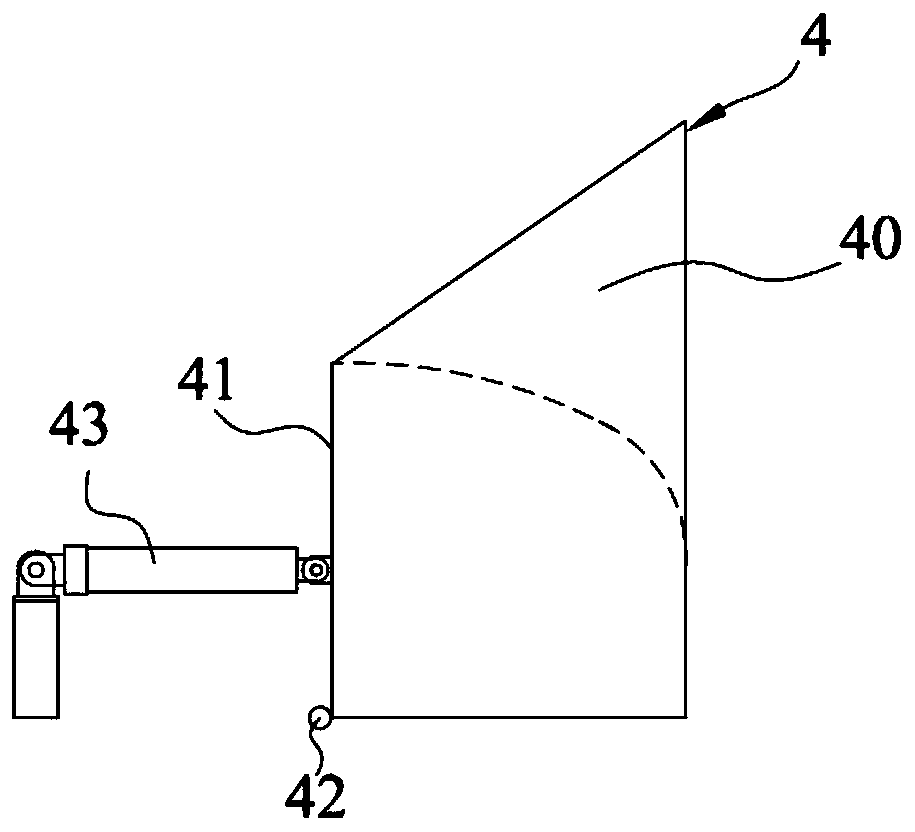

[0043] refer to figure 1 The preferred first embodiment of the present invention provides a garbage transfer station, which includes a protective cover 100, a compression box 1 is provided in the protective cover 100, and a push blade 2 for squeezing materials to be processed is provided in the compression box 1, A feeding box 4 is arranged above the compression box 1, and a feeding mechanism 6 for collecting and lifting waste materials to be treated in the ground or pits into the compression box 1 is arranged behind the compression box 1, and a deodorizing mechanism is arranged above the compression box 1 7 and the hydraulic station 8, a sewage settling box 5 and a sewage treatment box 9 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com