Real-time deviation correction method based on robot gluing

A robot and gluing technology, applied to the device and coating of the surface coating liquid, to achieve the effect of ensuring reliability, reducing labor costs, and realizing control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below with reference to the embodiments and accompanying drawings, but the embodiments of the present invention are not limited thereto.

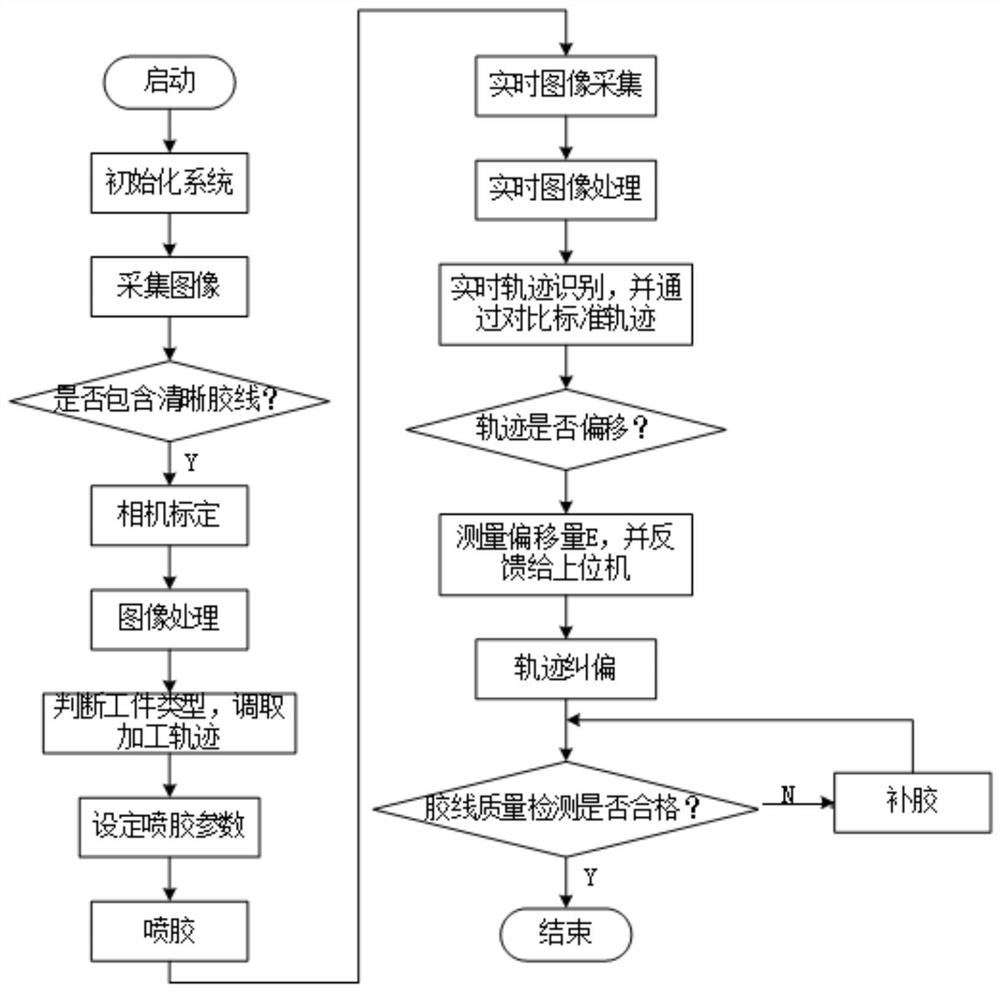

[0016] Such as figure 1 As shown, the present invention proposes a real-time deviation correction method for robot gluing based on machine vision, intends to develop a set of devices integrating on-line monitoring and deviation correction system, image acquisition device and gluing robot, and proposes a set of integrated algorithms, completely The software automatically compares and judges the real-time gluing curve with the preset standard and simulated ideal trend, instead of manually completing the empirical judgment task, and subdivides the deviation detection part into two aspects of comparison work, which is extremely Greatly improve the ability and accuracy of detection deviation, the algorithm mainly includes the following work: first complete the work of gluing image ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com