C-Bi2O3-CuO-ZnO adsorbing material and preparation method and application thereof

A c-bi2o3-cuo-zno, adsorption material technology, applied in chemical instruments and methods, adsorption water/sewage treatment, water/sludge/sewage treatment, etc. and other problems, to achieve the effect of overcoming uneven heating, good adsorption and removal effect, and no temperature gradient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A C-Bi 2 o 3 -The preparation method of CuO-ZnO adsorption material, comprises the following steps:

[0028] S1, adding bismuth nitrate, copper nitrate, zinc acetate and gac into 50mL concentration is in the dilute nitric acid solution of 0.15mol / L, makes bismuth nitrate, copper nitrate, zinc acetate dissolve, obtains mixed solution;

[0029] S2. Adjust the pH of the mixed solution in step S1 to 5-12 with an ammonia solution to obtain a reaction solution;

[0030] S3. Under stirring and microwave conditions, the reaction solution described in step S2 was hydrothermally reacted at 100°C for 20 minutes. The reaction vessel was the XH-800SP multifunctional microwave hydrothermal parallel synthesizer reactor produced by Beijing Xianghu Technology Co., Ltd., tank The body pressure is 3Mpa; then dry at 150°C for 3h to obtain C-Bi 2 o 3 -CuO-ZnO adsorption material, where the microwave power is 1000W.

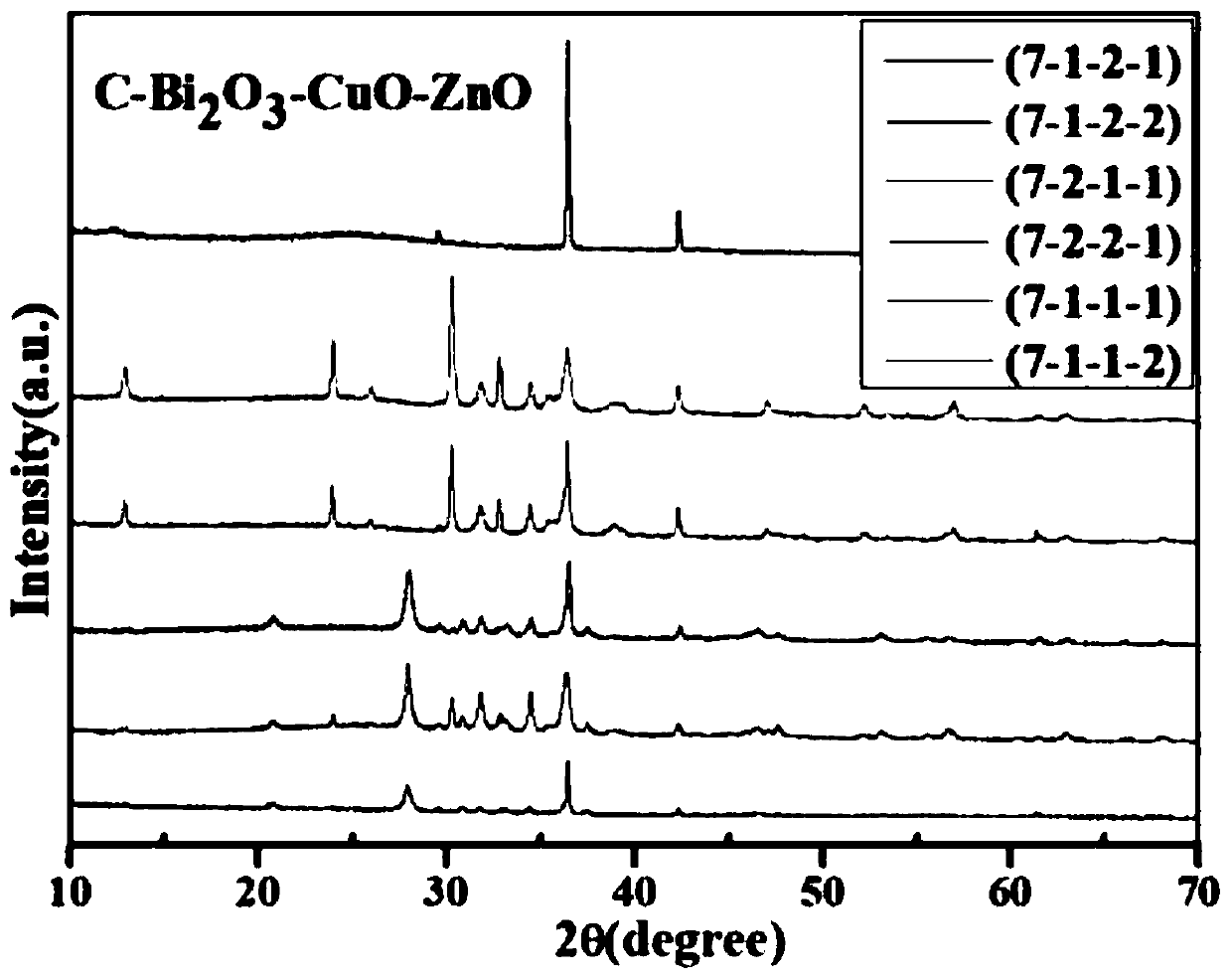

[0031] According to the above preparation method, C-Bi 2 o 3 -CuO-Z...

Embodiment 2

[0033] A C-Bi 2 o 3 -The preparation method of CuO-ZnO adsorption material, comprises the following steps:

[0034] S1, adding bismuth nitrate, copper nitrate, zinc acetate and gac into 50mL concentration is in the dilute nitric acid solution of 0.15mol / L, makes bismuth nitrate, copper nitrate, zinc acetate dissolve, obtains mixed solution;

[0035] S2. Adjust the pH of the mixed solution in step S1 to 5-12 with an ammonia solution to obtain a reaction solution;

[0036] S3. Under stirring and microwave conditions, the reaction solution described in step S2 was hydrothermally reacted at 100°C for 20 minutes. The reaction vessel was the XH-800SP multifunctional microwave hydrothermal parallel synthesizer reactor produced by Beijing Xianghu Technology Co., Ltd., tank The body pressure is 3Mpa; then dry at 150°C for 3h to obtain C-Bi 2 o 3 -CuO-ZnO adsorption material, where the microwave power is 1000W.

[0037] According to the above preparation method, C-Bi 2 o 3 -CuO-Z...

Embodiment 3

[0039] A C-Bi 2 o 3 -The preparation method of CuO-ZnO adsorption material, comprises the following steps:

[0040] S1, adding bismuth nitrate, copper nitrate, zinc acetate and gac into 50mL concentration is in the dilute nitric acid solution of 0.15mol / L, makes bismuth nitrate, copper nitrate, zinc acetate dissolve, obtains mixed solution;

[0041] S2. Adjust the pH of the mixed solution in step S1 to 5-12 with an ammonia solution to obtain a reaction solution;

[0042] S3. Under stirring and microwave conditions, the reaction solution described in step S2 was hydrothermally reacted at 100°C for 20 minutes. The reaction vessel was the XH-800SP multifunctional microwave hydrothermal parallel synthesizer reactor produced by Beijing Xianghu Technology Co., Ltd., tank The body pressure is 3Mpa; then dry at 150°C for 3h to obtain C-Bi 2 o 3 -CuO-ZnO adsorption material, where the microwave power is 1000W.

[0043] According to the above preparation method, C-Bi 2 o 3 -CuO-Z...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com