Method for purifying thermally stable salt in desulfurization amine solution

A technology of desulfurization amine solution and heat-stable salt, which is applied in the field of water treatment, can solve the problems of difficult removal of heat-stable salt, small adsorption capacity, and improvement of removal rate of heat-stable salt, and achieve easy handling, high-efficiency removal, The effect of reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

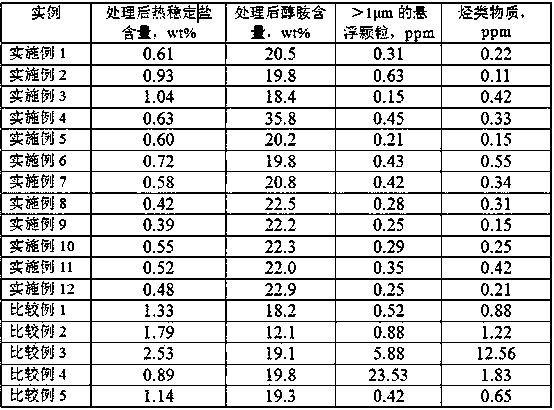

Examples

Embodiment 1

[0044] Purification treatment of desulfurized amine liquid in a refinery, with a treatment capacity of 5m 3 / h. The alcohol amine solution used is an aqueous solution of methyldiethanolamine (MDEA), wherein the mass content of methyldiethanolamine is 23%. In the desulfurization amine liquid, the mass content of heat stable salt is 5.5%, wherein the anion of heat stable salt includes CH 3 COO - , SO 4 2- , SO 3 2- , SCN - , Cl - ; The mass content of bound amine is 1.3%, and the mass content of main metal ion is 0.9%Na + , 0.2%K + , 0.3%Fe 3+ ; Among them, the content of solid suspended particles with a diameter greater than 1 μm is 2000 ppm, and the content of hydrocarbon substances is 2000 ppm.

[0045] Filter the desulfurized amine solution to remove solid suspended particles. Filtration adopts two-stage series filter element filter, the filter element precision of the filter is 10μm and 2μm, and the filtration speed is 5m 3 / h. Two-stage series element filters...

Embodiment 2

[0050] Treat the same desulfurized amine solution as in Example 1.

[0051] Filtration adopts two-stage series filter element filter, the filter element precision of the filter is 40μm and 5μm, and the filtration speed is 10m 3 / h. Two-stage series element filters are set up in two groups or more in parallel, and operate alternately. When the pressure difference between the two ends of the filter increases by 50% after filtering, switch to another group for operation. Use desalinated water to backwash the used filter, the backwash cycle is 10 days, and the backwash water speed is 20L / m 2 ·s. After filtration, the removal rate of solid suspended particles with a particle size greater than 1 μm is 91%.

[0052] The activated carbon adsorption tower is filled with coconut shell activated carbon spherical particles with a height of 2m, the particle diameter is 4mm, and the flow rate of the regenerated amine liquid is 10m 3 / h, the residence time is 90min. Two or more sets of ...

Embodiment 3

[0055] Treat the same desulfurized amine solution as in Example 1.

[0056] Filtration adopts two-stage series filter element filter, the filter element precision of the filter is 5μm and 1μm, and the filtration speed is 1m 3 / h. Two-stage series element filters are set up in two groups or more in parallel, and operate alternately. When the pressure difference between the two ends of the filter increases by 10% after filtering, switch to another group for operation. Use desalinated water to backwash the used filter, the backwash cycle is 1 day, and the backwash water speed is 5L / m 2 ·s. After filtration, the removal rate of solid suspended particles with a particle size greater than 1 μm is 97%.

[0057] The activated carbon adsorption tower is filled with coconut shell activated carbon spherical particles with a height of 1m, the particle diameter is 1mm, and the flow rate of the regenerated amine liquid is 1m 3 / h, the residence time is 30min. Two or more sets of activa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com