Temperature-swing adsorption process

一种变温吸附、吸附剂的技术,应用在分离方法、化学仪器和方法、弥散粒子分离等方向,能够解决吸附材料不常见、昂贵等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

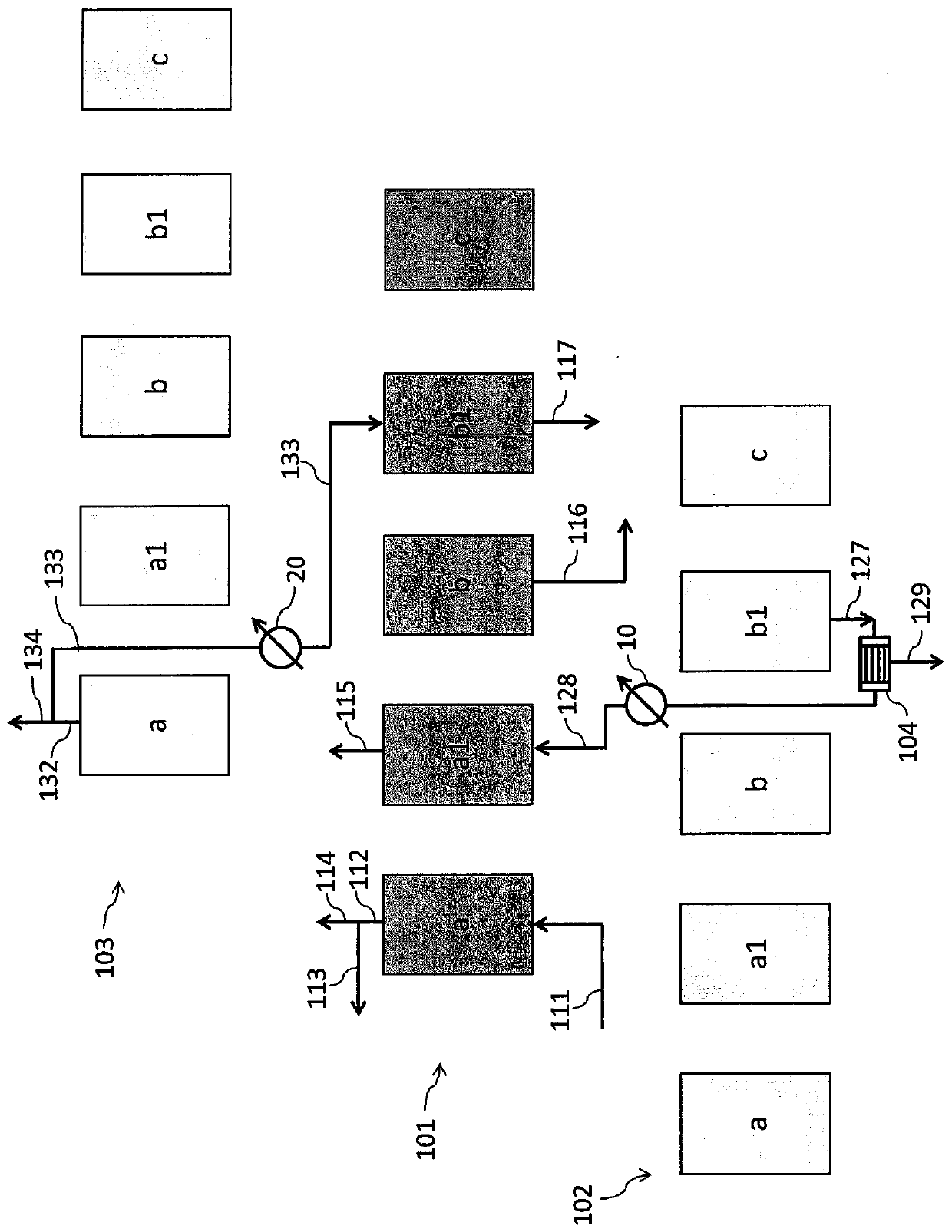

[0103] figure 1 Example of

[0104] refer to figure 1 , the method of the present invention is carried out in a plurality of reactors, for example, including reactors 101 , 102 , 103 . Each reactor 101-103 contains a fixed bed of an adsorbent for the component of interest, for example, zeolite 13X for the adsorption of carbon dioxide.

[0105] Each reactor carries out multiple steps, namely: first adsorption step (a), second adsorption step (a1), desorption step (b), purging step (b1), conditioning step (c) and condensation step. The reactors are interconnected and in some of the process steps a reactor can exchange one or more gas streams with one or more other reactors. exist figure 1 In , boxes (a), (a1), (b), (b1), (c) represent the reactors 101 , 102, 103 when the process steps are carried out.

[0106] During the first adsorption step (a), the gas to be treated (eg flue gas) is introduced into the reactor, the target component is adsorbed, an off-gas stream is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com