Automatic insulation paper inserting machine for motor stator

A motor stator and insulating paper technology, applied in the direction of laying solid insulation, etc., can solve the problems of low processing efficiency, high motor production cost, low production efficiency, etc., and achieve the effect of high paper insertion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

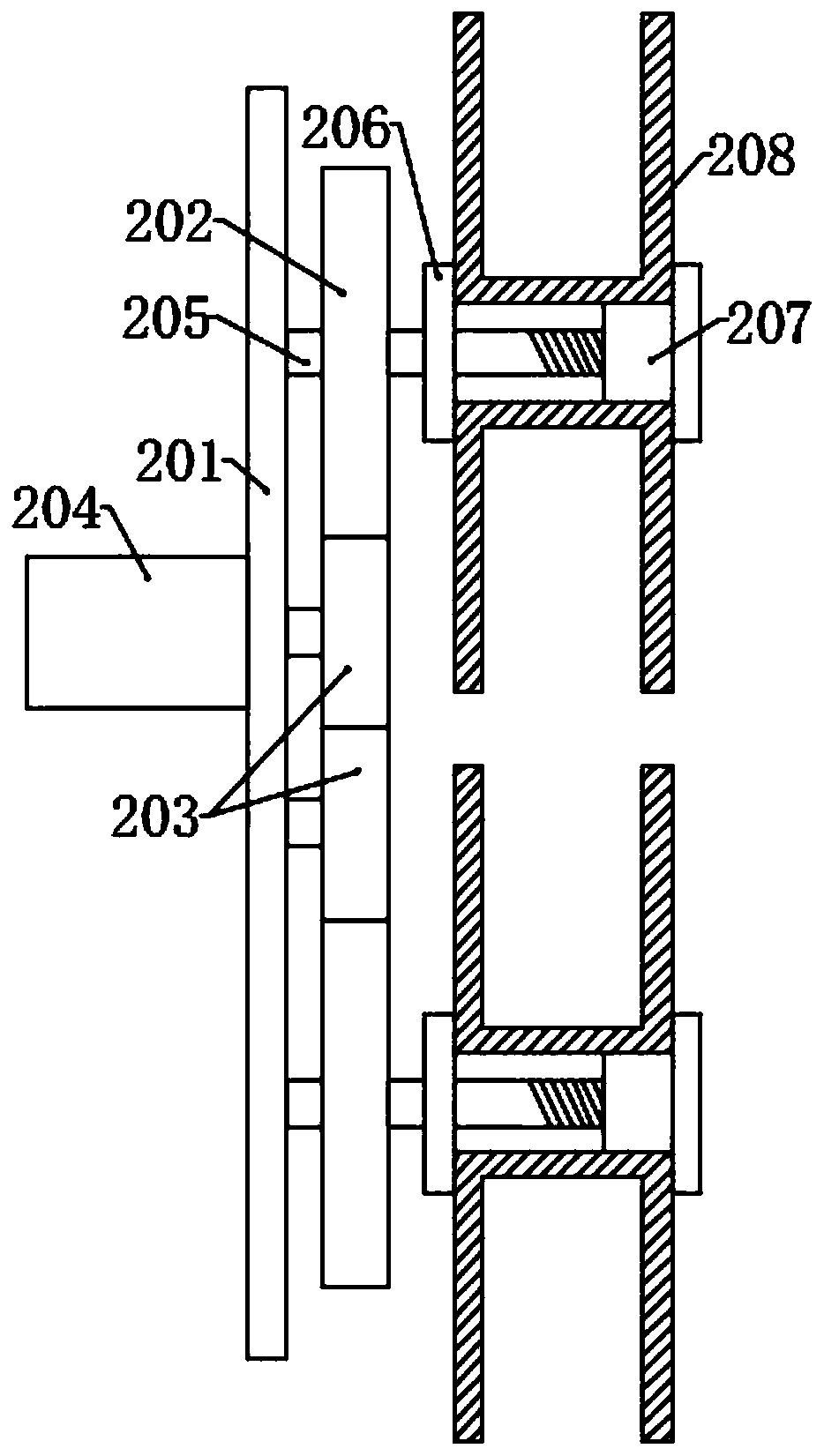

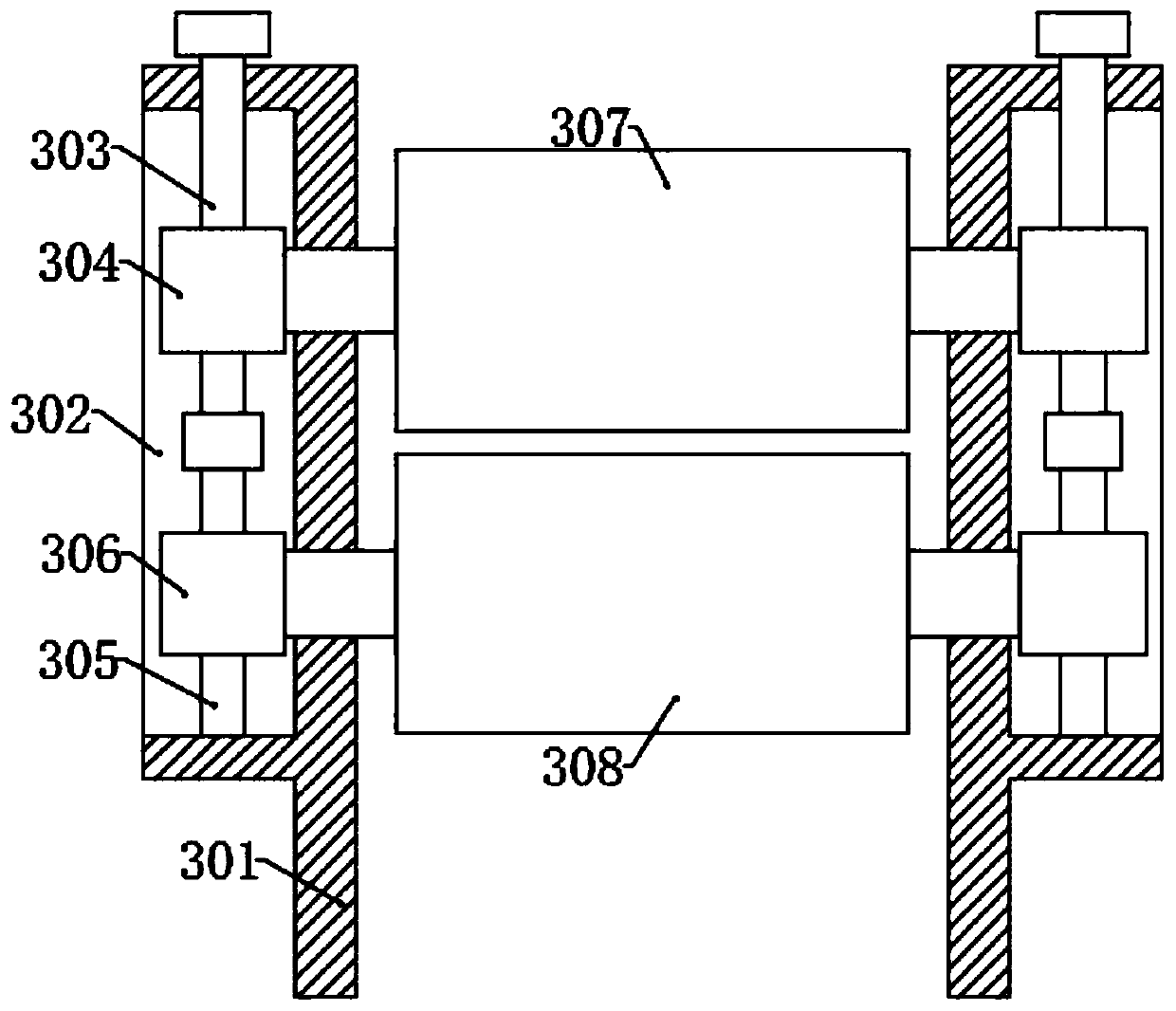

[0035] Please refer to the accompanying drawings, the present invention provides a technical solution: an automatic paper insertion machine for insulating paper for motor stators, including a support mechanism 1 and a paper release mechanism 2, the support mechanism 1 includes a bottom plate 101, and four corners of the bottom surface of the top plate 105 A lower support bar 103 is fixed, an upper support bar 104 is fixed at the four corners of the top surface, and a top plate 105 is fixed through the upper support bar 104. The paper release mechanism 2 is arranged on the top plate 105, and the top surface of the bottom plate 101 is provided with a The stator fixing mechanism 6, and one side of the stator fixing mechanism 6 is provided with the first forming mechanism 5, the first preloading mechanism 4 and the first guiding mechanism 3 sequentially from the inside to the outside, and the other side is sequentially provided with the second Forming mechanism 7, the second pre-pr...

Embodiment 2

[0044] On the basis of Embodiment 1, the stator fixing mechanism 6 further includes a rotating plate 12, on which a plurality of fixed ring plates 11 are evenly arranged along the circumferential direction, and the fixed ring plates 11 are connected with a driving gear 1106 and a gear motor, A first motor is connected to the center of the rotating plate 12 .

[0045] A plurality of fixed ring plates 11 on the rotating plate 12 may be able to fix multiple electrons at the same time. When one of the stators is inserted into the paper, the rotating plate 12 is rotated by the first motor, and the paper is inserted into the next stator, so that the multiple stators Continuous processing improves work efficiency.

Embodiment 3

[0047]On the basis of Embodiment 2, the stator fixing mechanism 6 also includes a rotating shaft 1202, and the base plate 101 is provided with a rotating groove corresponding to the stator fixing mechanism 6, and the bottom surface of the base plate 101 is fixed with a turret, and the rotating shaft 1202 and The turret is rotatably connected, and one end of the rotating shaft 1202 is connected with a second motor, and four rotating rods 1201 are fixed along the circumferential direction on the rotating shaft 1202, and the outer end of the rotating rod 1201 is rotatably connected with a rotating plate 12 .

[0048] More stators are further fixed by the four rotating plates 12 and the fixed ring plate 11 on the rotating plate 12, and the rotating plate 12 on the upper part of the rotating shaft 1202 is in the working state of continuous paper insertion, while the rotating plates 12 on both sides are respectively in In the state of loading and unloading, the working state is switc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com